Rail outline detection method based on abrasion value

A detection method and wear value technology, applied in the direction of railway vehicle shape measuring device, railway car body parts, railway auxiliary equipment, etc., can solve the problems of limited measurement range, inability to obtain part data of rail waist, and difficulty in alignment of measurement results, etc., to achieve The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

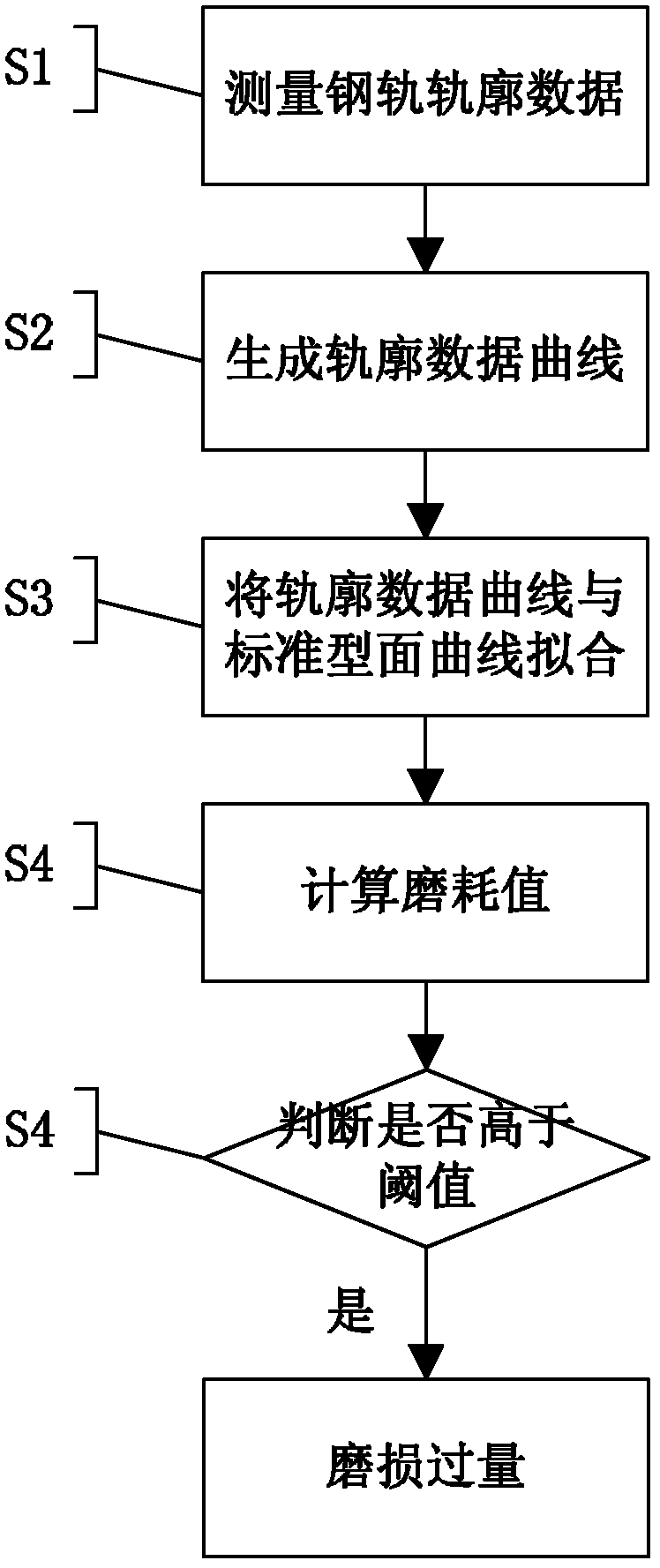

[0029] A rail profile detection method based on wear value, its processing flow is as follows figure 1 shown, including the following steps:

[0030] Step S1: Measure the rail profile data by the rail profile measuring instrument, the measured data does not include the data of the rail waist part, and send it to the data processing device;

[0031] Step S2: the data processing device generates a rail profile data curve through the rail profile data;

[0032] Step S3: Fitting the rail profile data curve with the standard profile curve, the principle of fitting is that there is basically no wear on the outer side and lower part of the rail head;

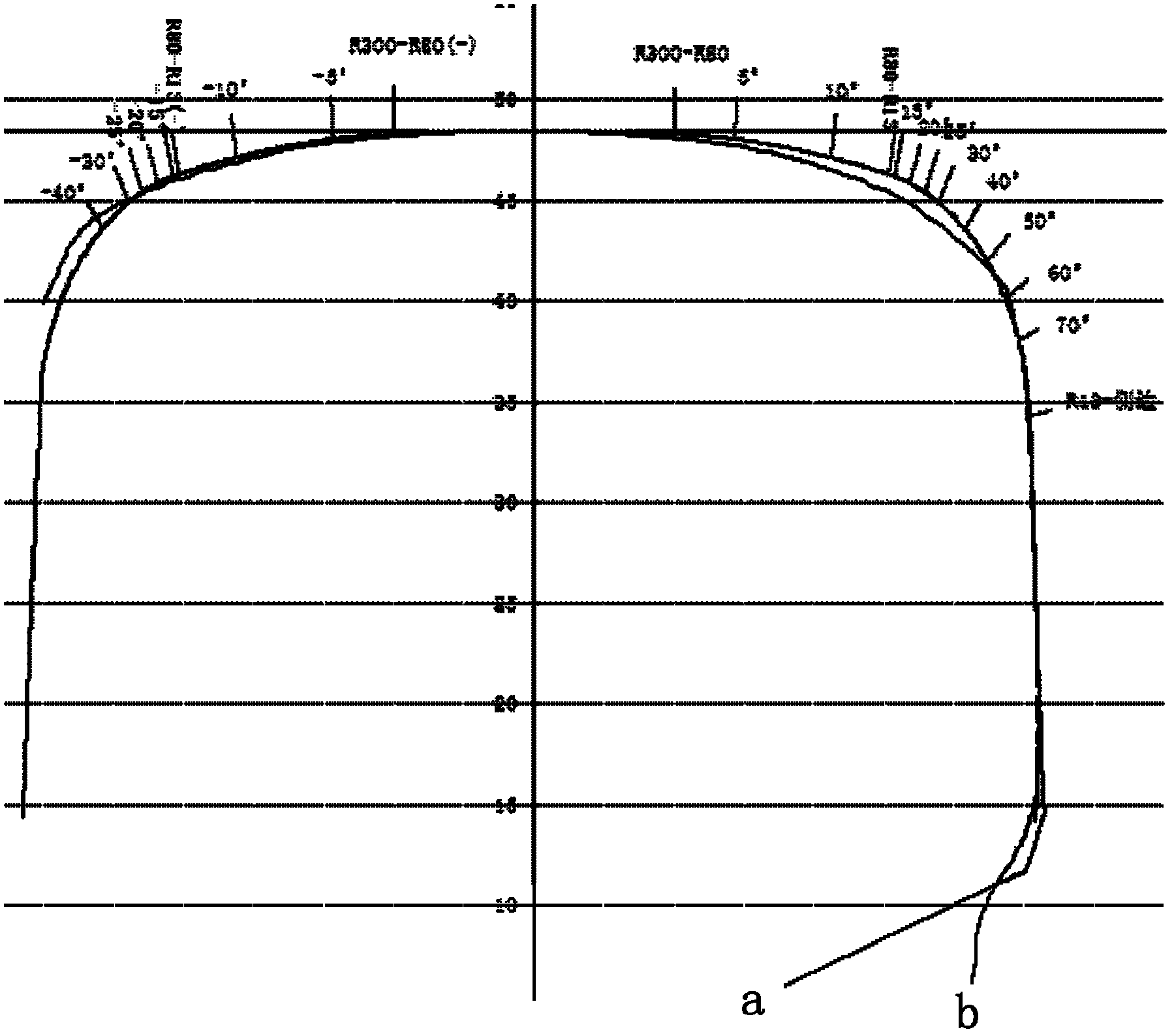

[0033] Step S4: Calculate the wear value at each position on the top of the rail according to the fitted contour data curve, and each position is marked by the angle between the tangent line of the point and the horizontal plane, and the angle range is 1-90°, such as figure 2 angle indicated in .

[0034] Step S5: Comparing the obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com