Packing case

A packaging box and box body technology is applied in the field of packaging boxes with a blocking angle structure on the inside, which can solve the problems of limited impact force on the side wall and easy damage to the side wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

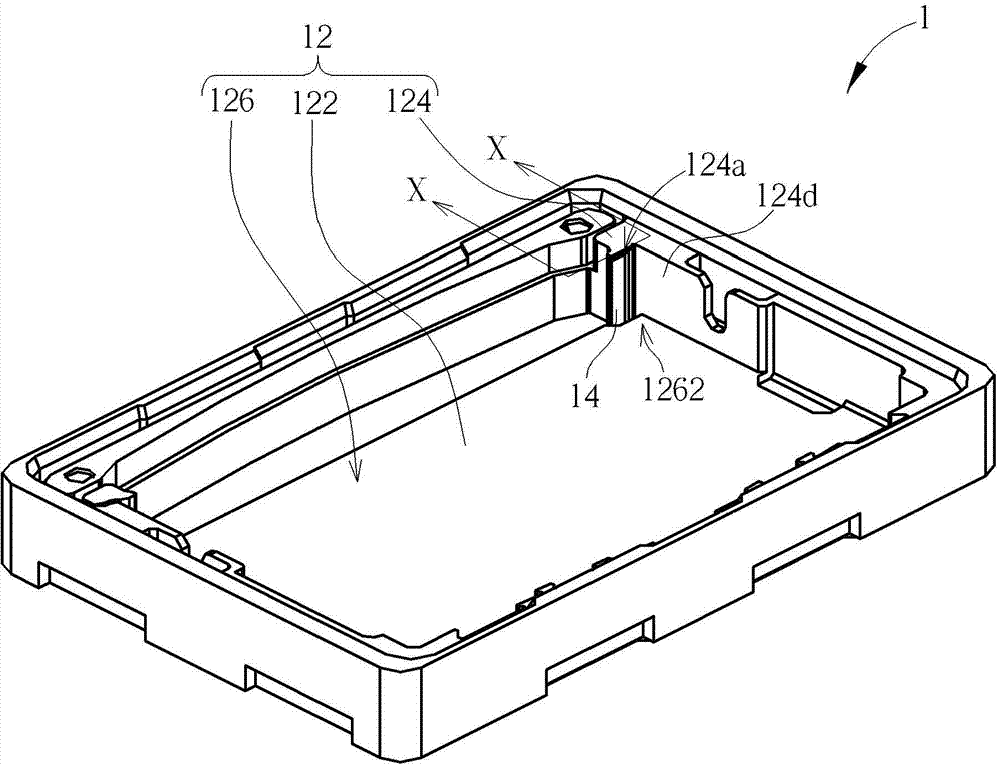

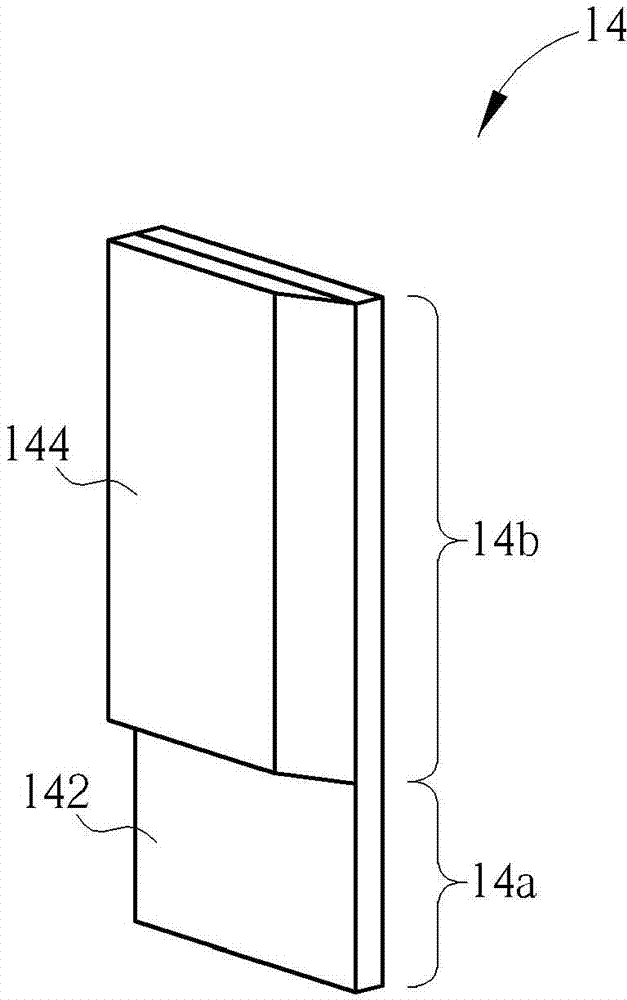

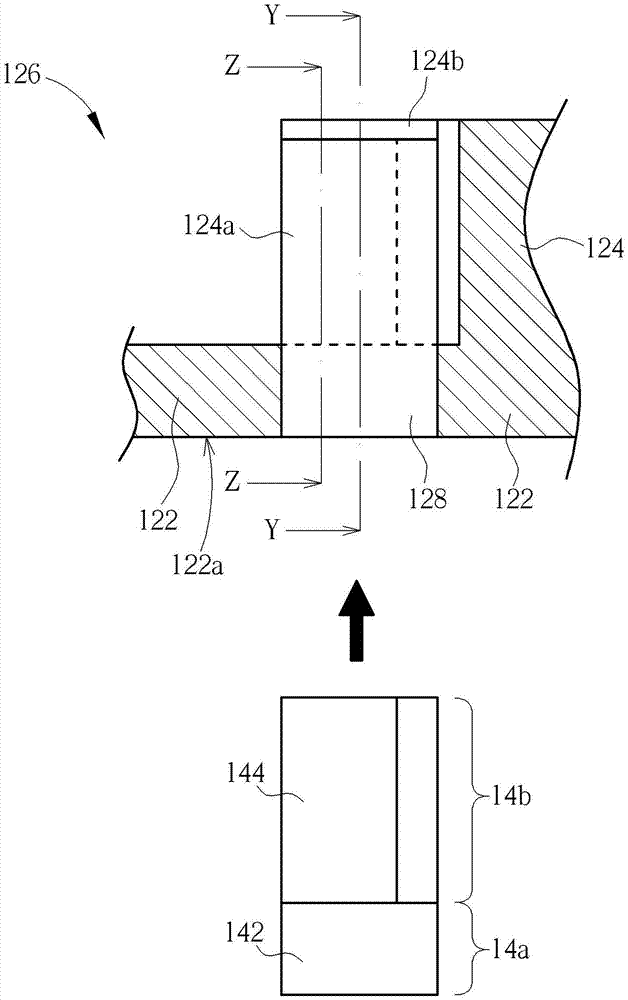

[0044] see figure 1 , which is a schematic diagram of a packing box 1 according to a preferred embodiment of the present invention. The packaging box 1 includes a box body 12 and a corner piece 14 . The box body 12 includes a bottom 122 and a side wall structure 124. The side wall structure 124 is arranged around the bottom 122 to form a housing space 126. The housing space 126 has a corner 1262 adjacent to one of a plurality of corners of the side wall structure 124 and Between the bottom 122. The corner block 14 is disposed at the corner 1262 . In practice, the box body 12 will be packaged with a top cover, but the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com