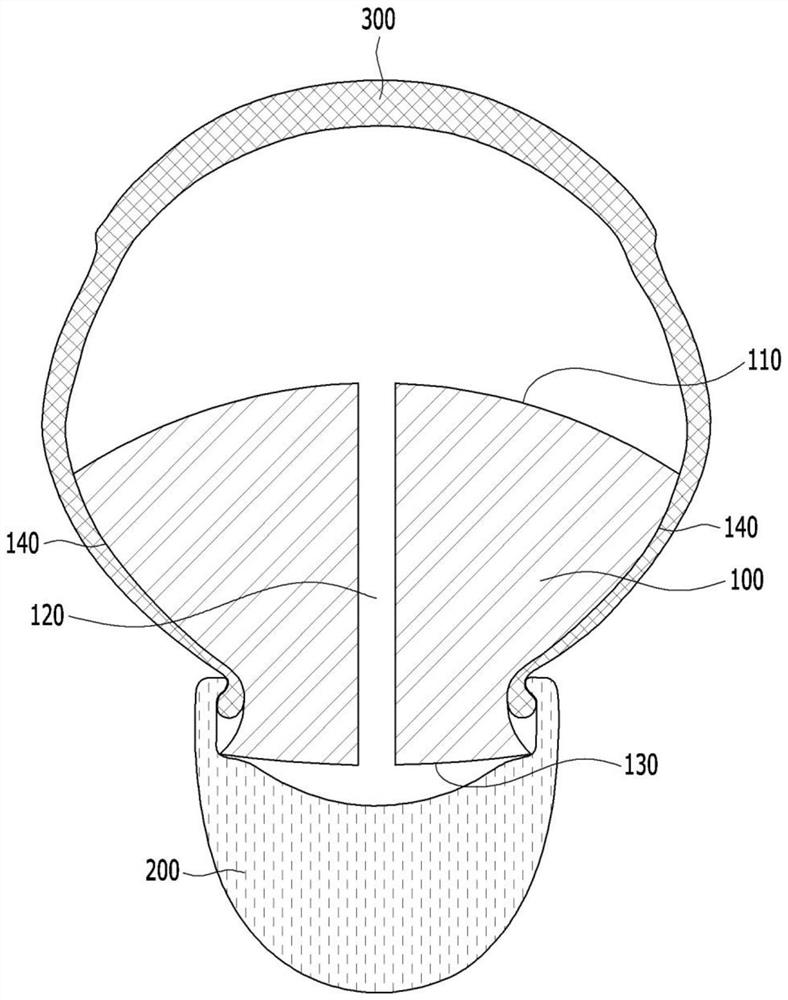

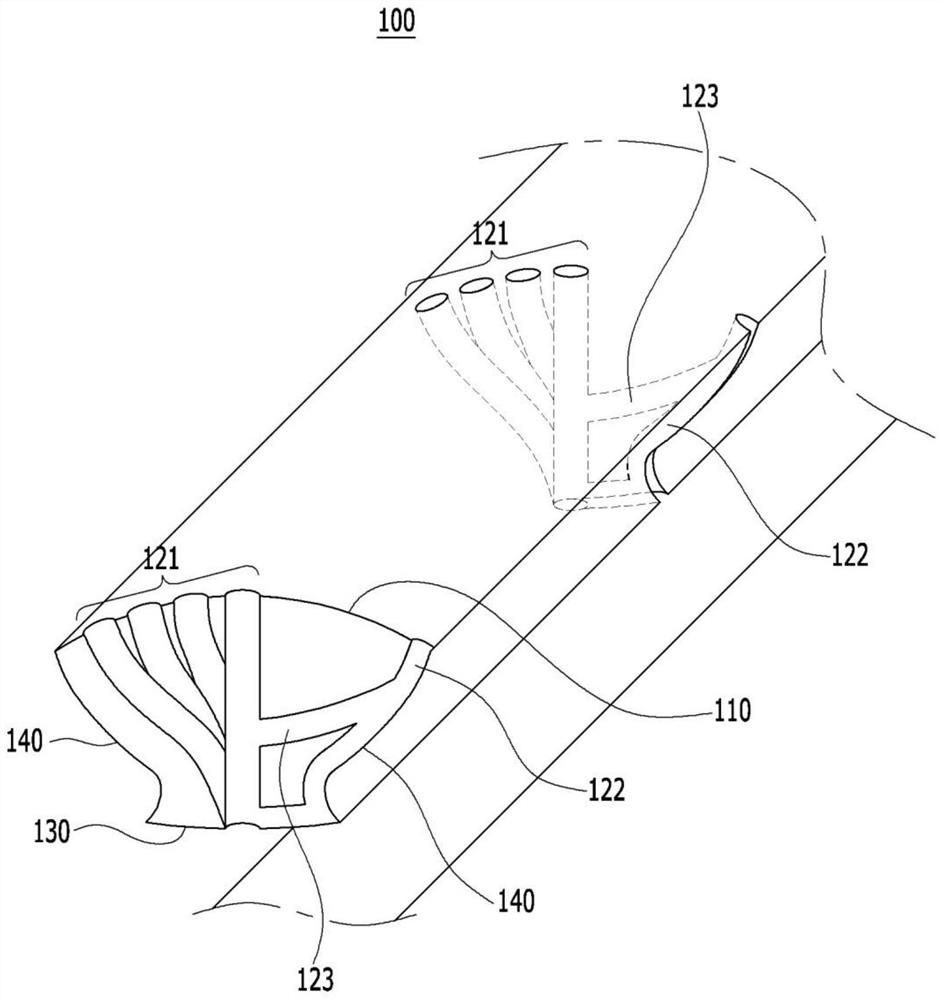

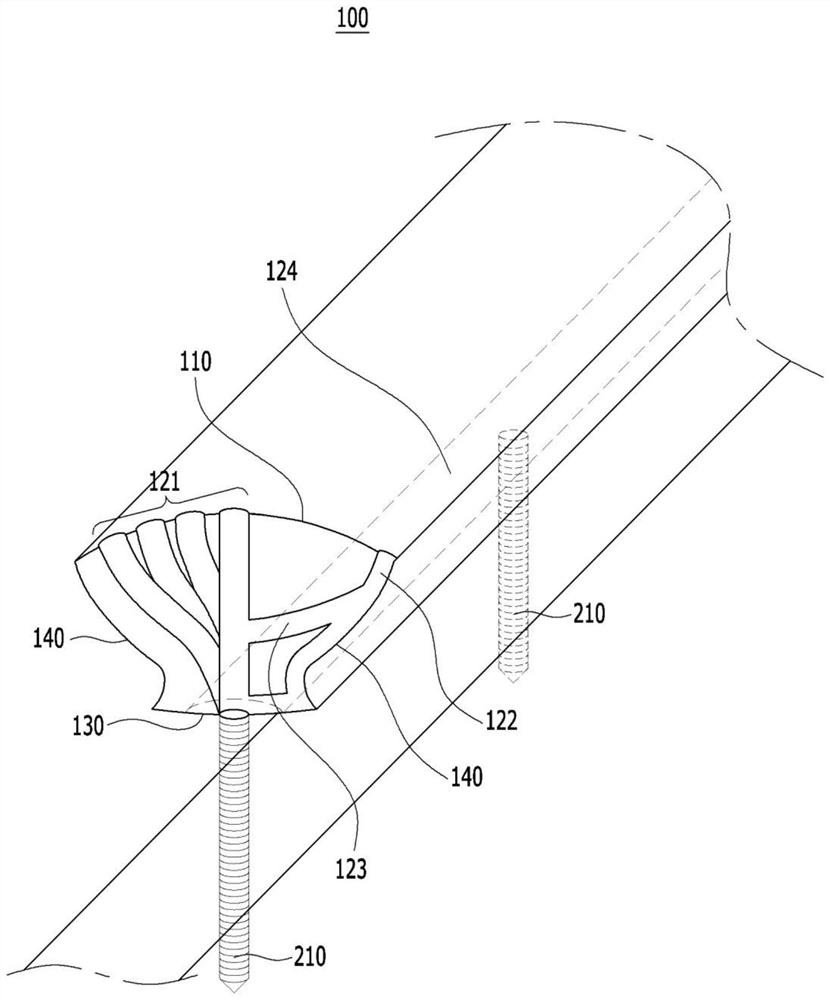

Tire insert

A technology of tires and inserts, applied to tire parts, pneumatic tires, bicycle tires, etc., can solve problems such as internal fluid circulation of tubeless tires, etc., and achieve easy installation, good shock absorption, and excellent rolling resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0119] As the conditions of Example 1, a Maxxis-Minion DHR 2 (27.5×2.3) tire was used, and the air pressure inside the tire was set at 10 psi.

[0120] In the experimental method of Example 1, the tire incorporating the insert was mounted on a pressure measuring device called a Load Cell, and 5 kg was dropped above the tire at a height of 300 mm The weight of the weight, and the force or load (kgf) applied to the load cell is measured by time, and the maximum load point (kgf) is selected as an index for evaluating the shock absorption performance.

[0121] The vibration in Example 1 was measured by rotating the drum with the tire in contact with the drum, and using a vibration measuring instrument capable of measuring in units of μm. At this time, the speed of the drum is 20 km / h, and the weight is 45 kg. The vibration was measured for 10 minutes after the start of driving to obtain an average value. For reference, the vibration measurement values in Table 1 below are disp...

Embodiment 2

[0141] As the conditions of Example 2, a Maxxis-Minion DHR 2 (27.5×2.3) tire was used, and the air pressure inside the tire was set at 10 psi. In addition, experiments were performed by adjusting the horizontal major diameter of the tire to 55 mm and adjusting the horizontal major diameter of the insert to a range of 5.5 mm to 110 mm. That is, using the ratio of the horizontal major diameter of the tire to the horizontal major diameter of the insert (w i / w t ) within the range of 0.1 to 2 for every 0.1 insert.

[0142] The hardness of Example 2 was adjusted with the expansion ratio under the same compounding conditions. In addition, the hardness of the insert 100 was measured by using a hardness testing method based on ASTM D2240. Inserts are used that increase hardness by 10 according to the amount of foaming within the range of Shore C hardness of 10 or more, Shore C hardness of 90 or less, Shore A hardness of 10 or more, and Shore A hardness of 90 or less.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com