Tension detection device

A technology of tension detection and tension, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of inaccurate and controllable tension adjustment values, and achieve improved work efficiency and stable construction performance, ease of operation, increased accuracy and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

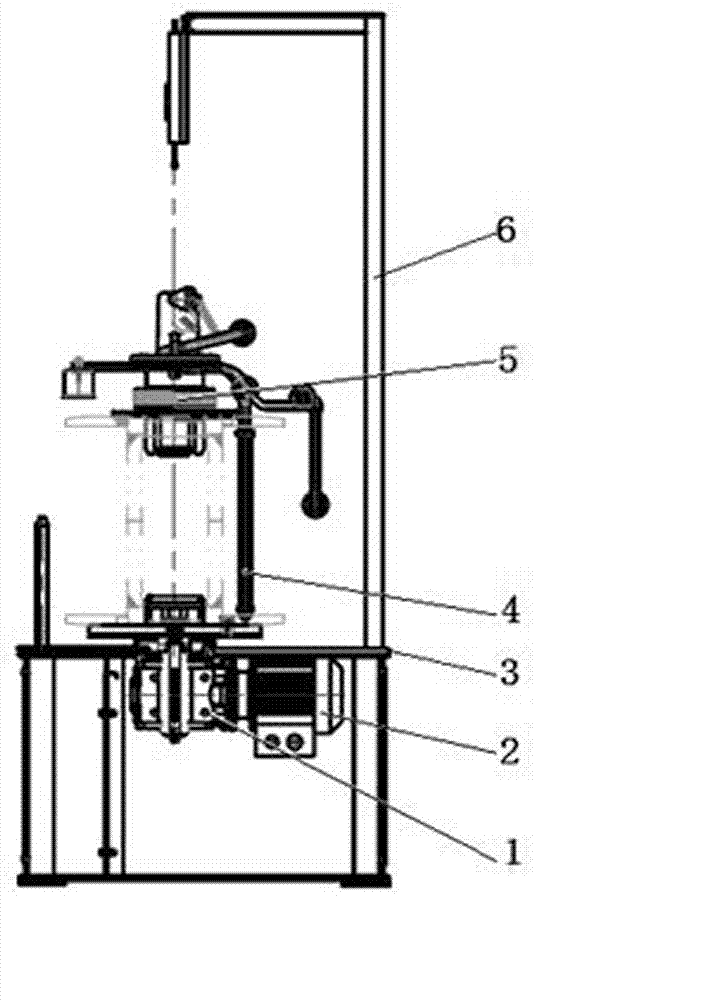

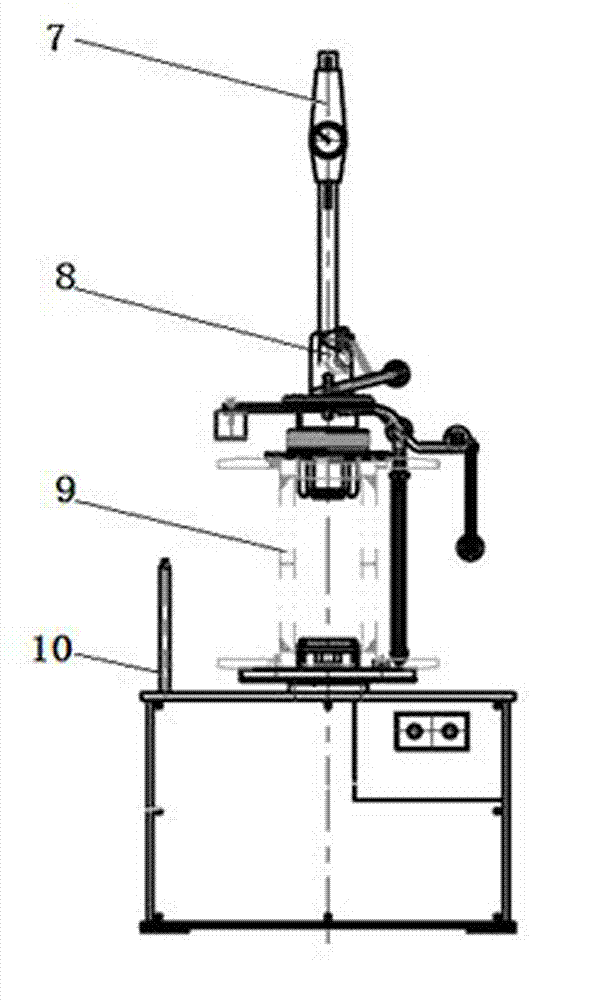

[0010] The tension detection device includes a tension machine 7, a wire payoff 8, a tension arm 5, a motor 2, and a reducer 1. The bracket 6 is vertically installed on the base 3. The top of the bracket 6 is hoisted with a tension machine 7. The motor 2 is connected to the reducer 1 , and installed under the base 3, the base 3 above the reducer 1 is provided with a protrusion to fix the I-shaped wheel 9, one side of the base 3 is the tension arm bobbin 4, and a tension arm bobbin 4 is provided above the tension arm bobbin 4. The arm 5 and the tension machine 7 are axially corresponding to the tension arm 5 , the top of the tension arm 5 is a wire release device 8 , and one side of the base 3 is provided with a clamping plate 10 . The motor 2 is controlled by the electric control system, and the speed of the reducer 1 is displayed by the display device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com