X-ray transmission inspection method

An inspection method and X-ray technology, applied in the field of X-ray transmission inspection, can solve the problems of a large number of images, need an X-ray generator, increase inspection costs, etc., and achieve the effects of high recognition rate, simple and fast process, and saving inspection costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

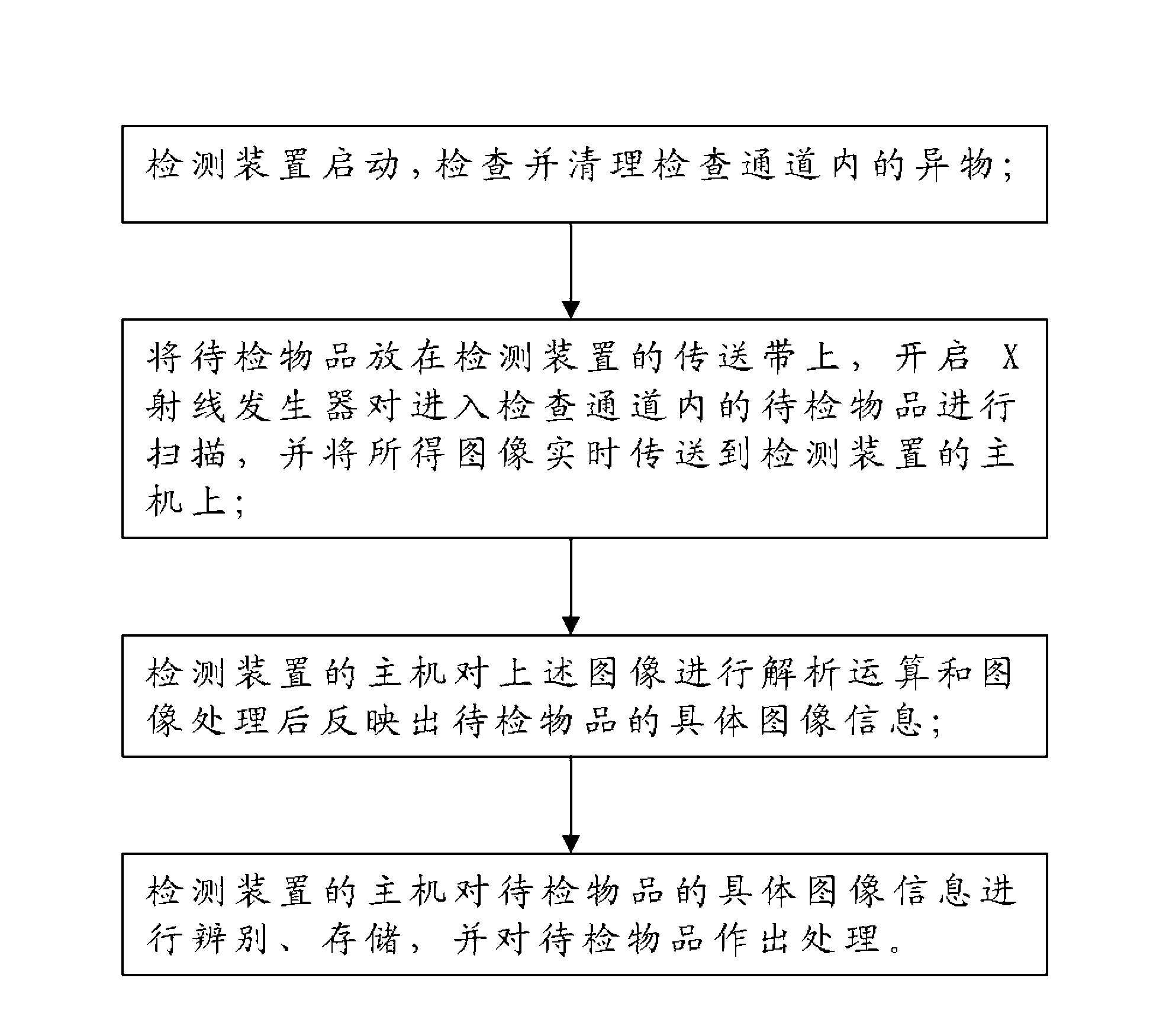

[0015] Such as figure 1 As shown, the X-ray transmission inspection method of the present invention comprises the following steps:

[0016] (1) Start the detection device, check and clean up the foreign matter in the inspection channel;

[0017] (2) Put the items to be inspected on the conveyor belt of the inspection device, turn on the X-ray generator to scan the articles to be inspected entering the inspection channel, and transmit the obtained images to the host of the inspection device in real time;

[0018] (3) The host computer of the detection device performs analysis, calculation and image processing on the above images to reflect the specific image information of the items to be inspected;

[0019] (4) The host computer of the detection device identifies and stores the specific image information of the items to be inspected, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com