Light guide plate and backlight unit with same

A technology of backlight module and light guide plate, which is applied in the field of backlight module and can solve the problem of small light output range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

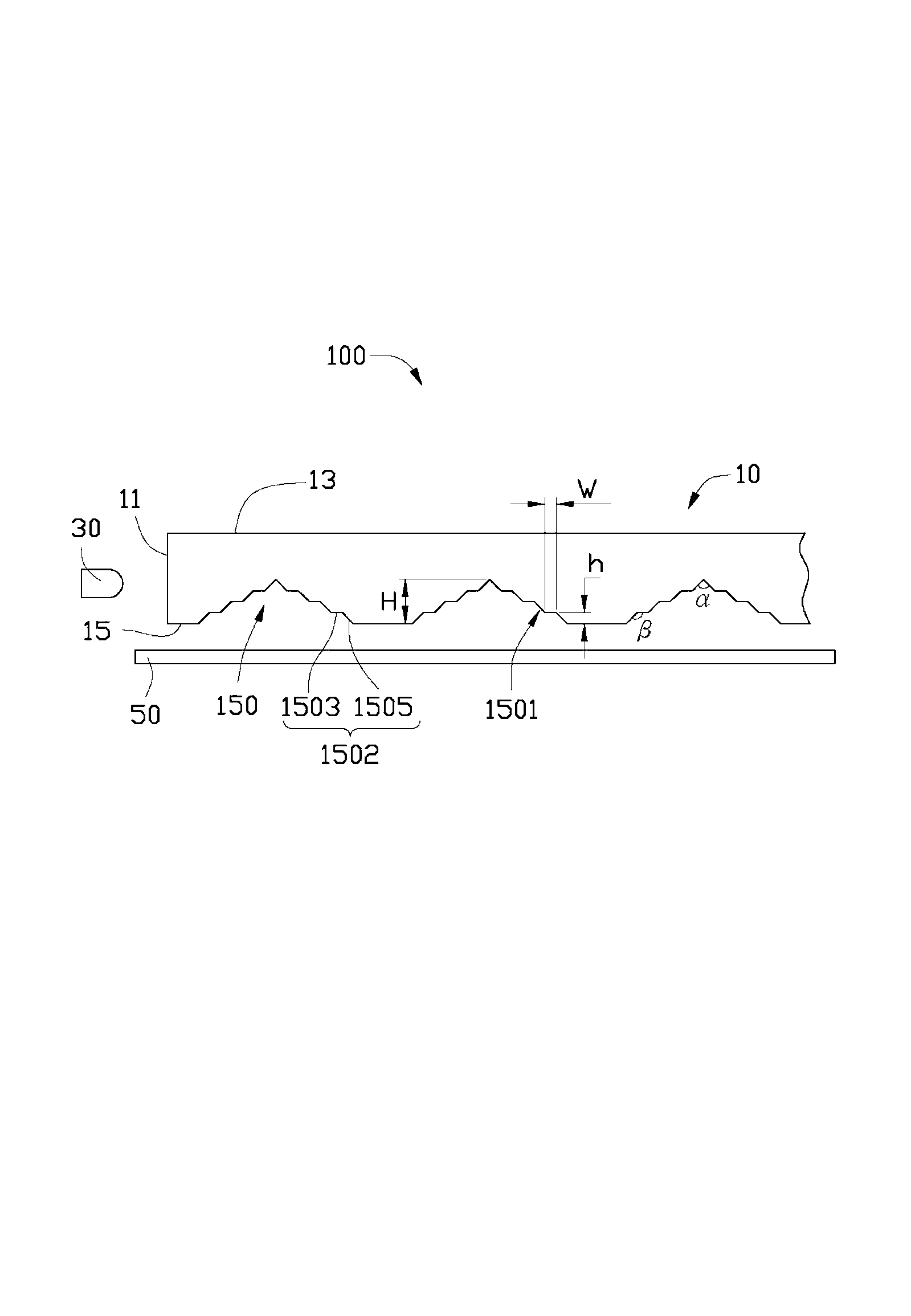

[0015] see figure 1 , the backlight module 100 according to Embodiment 1 of the present invention includes a light guide plate 10 , a light source 30 and a reflector 50 .

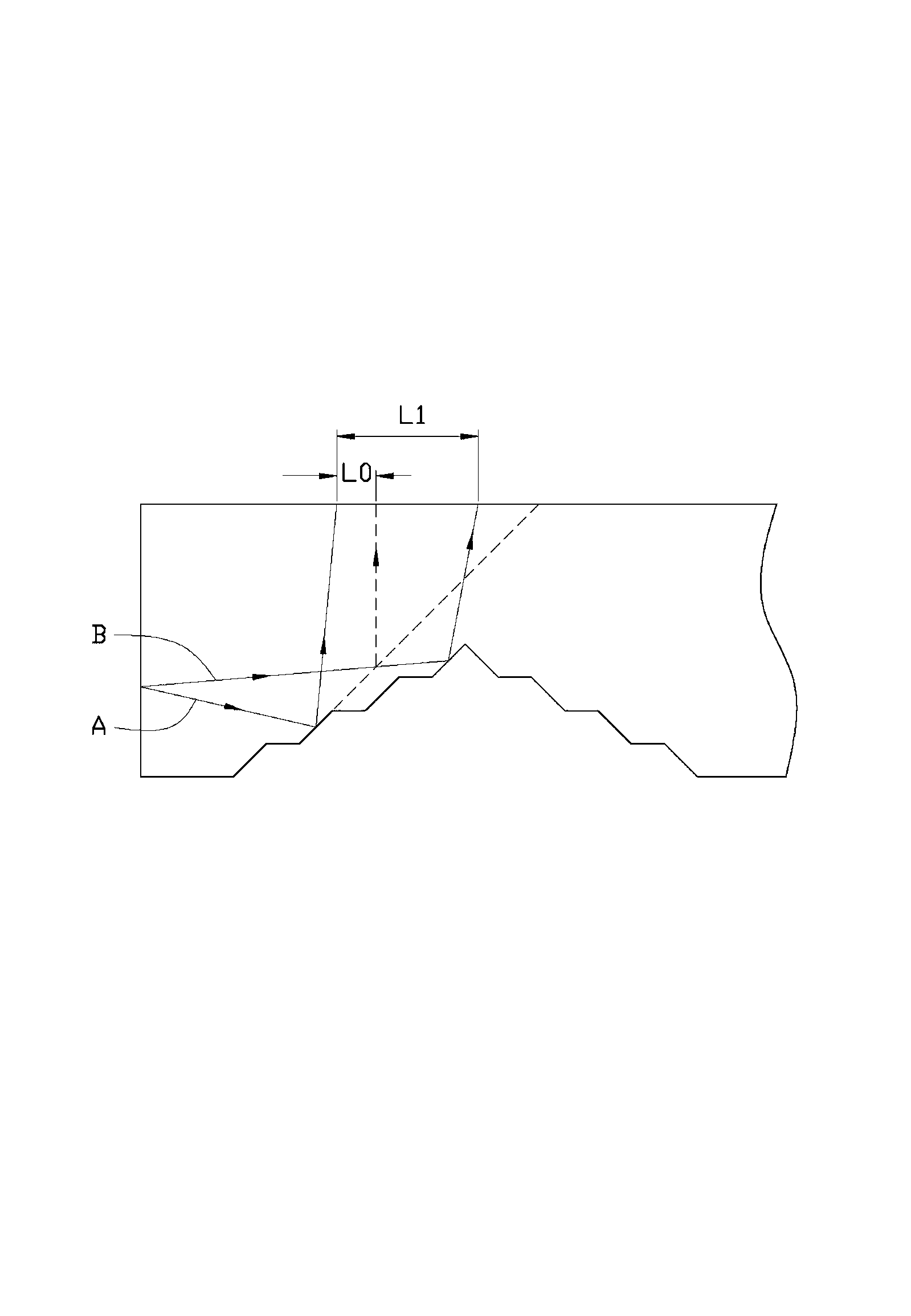

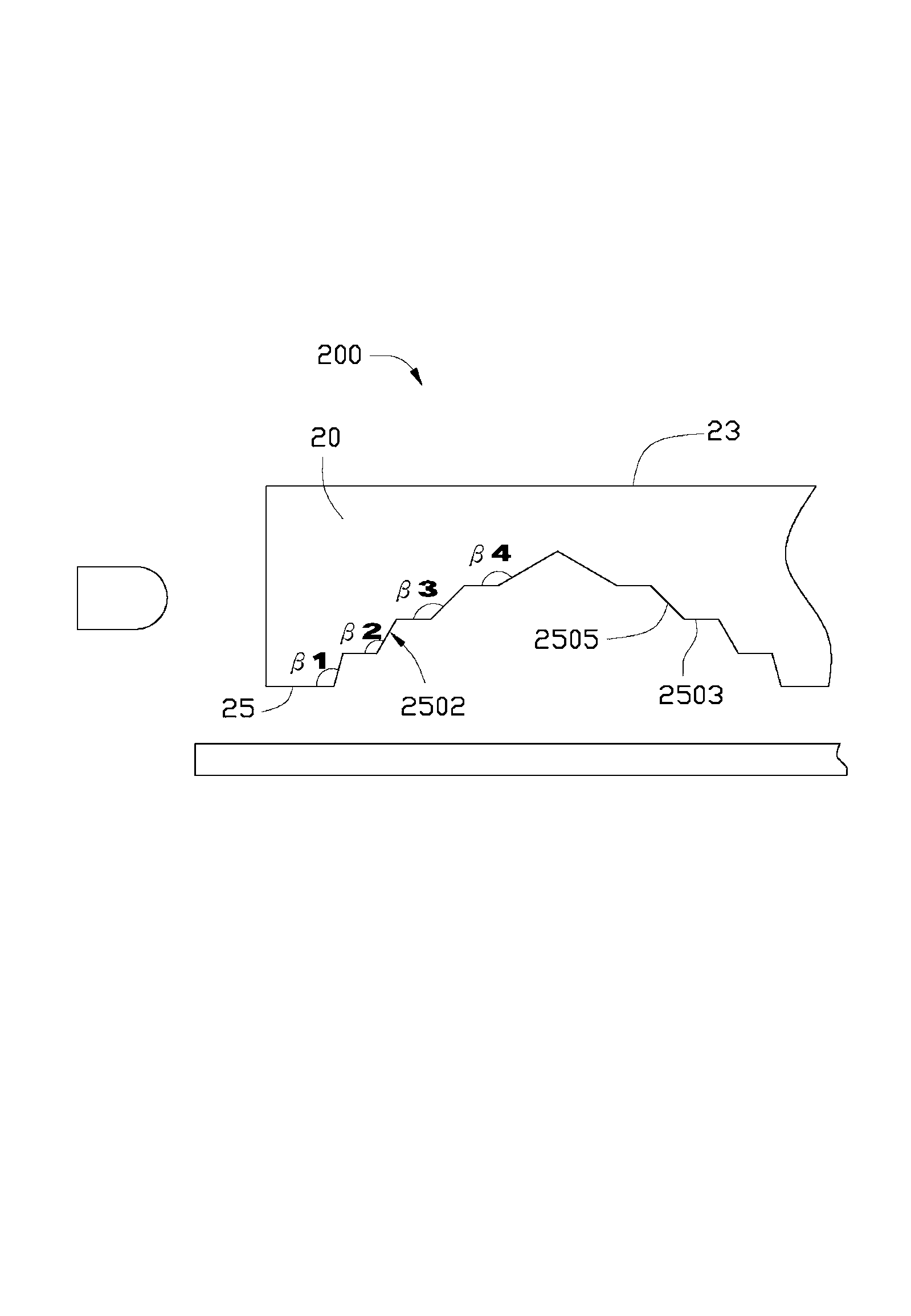

[0016] The light guide plate 10 is substantially in the shape of a rectangular plate, and has an incident surface 11 , an outgoing surface 13 , and a reflective surface 15 opposite to the outgoing surface 13 . The incident surface 11 connects the outgoing surface 13 and the reflective surface 15 , light enters the light guide plate 10 from the incident surface 11 , is reflected by the reflective surface 15 , and exits from the outgoing surface 13 . A plurality of parallel microstructures 150 recessed toward the inside of the light guide plate 10 are formed on the reflective surface 15 . The microstructure 150 is an elongated groove with a substantially inverted V-shaped cross section. The microstructure 150 is formed with two substantially symmetrical sidewalls 1501 , each sidewall 1501 includes a plurali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com