Spring manipulater used for breaker and breaker

A technology of breakers and manipulators, which is applied in the direction of convenient operation, contact operating mechanism, high-voltage air circuit breaker, etc. It can solve the problems such as the decrease of contact moving speed, the increase of driving force transmission loss, and the difficulty in increasing the rotation speed of the main rod. Achieve the effect of reducing the number of connections and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

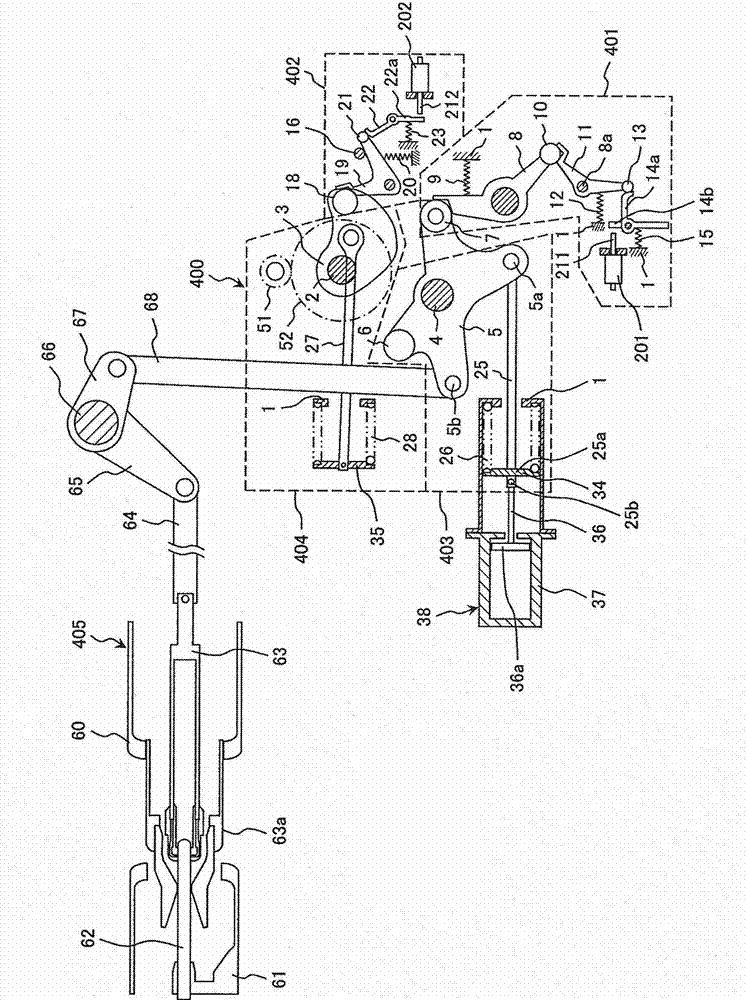

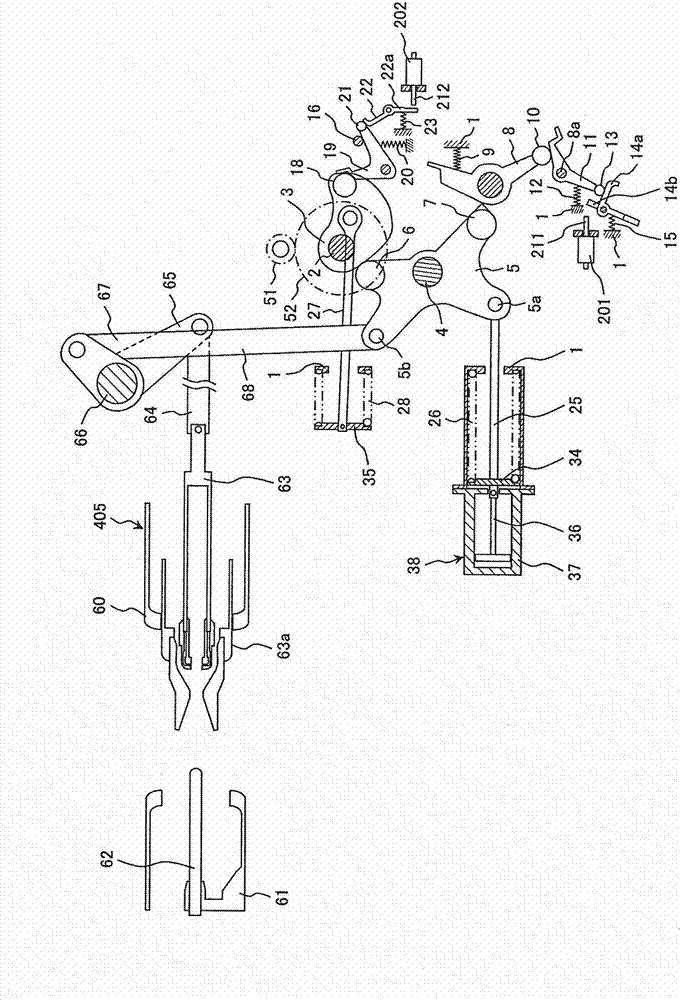

[0045] First, use Image 6 An air circuit breaker which is an embodiment of the breaker of the present invention will be described. As shown in the figure, the cylindrical grounded container 103 of the air circuit breaker 100 is installed on a stand 105 . Insulating gas, such as SF 6 For gas (sulfur hexafluoride gas), sleeves 101 and 102 protrude obliquely upward from an axially intermediate portion of a cylindrical grounded container 103 . Conductors that connect electric wires in substations and switching stations to form circuits are housed in sleeves 101 and 102 . In addition, an operation box 104 for accommodating an operation portion of the air circuit breaker 100 is attached to a side portion of the stand 105 .

[0046] In the air circuit breaker 100 configured in this way, for example, power is supplied to the sleeve 102 on the upstream side from a system not shown when energized. Then, it is guided from the sleeve 102 to the contact in the ground container 103 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com