Online automatic real-time centering method and device for cold drawing forming

A centering device and automatic technology, applied in the field of centering methods and devices, which can solve the problems of inconsistent finished product specifications, equipment deviation, defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the drawings.

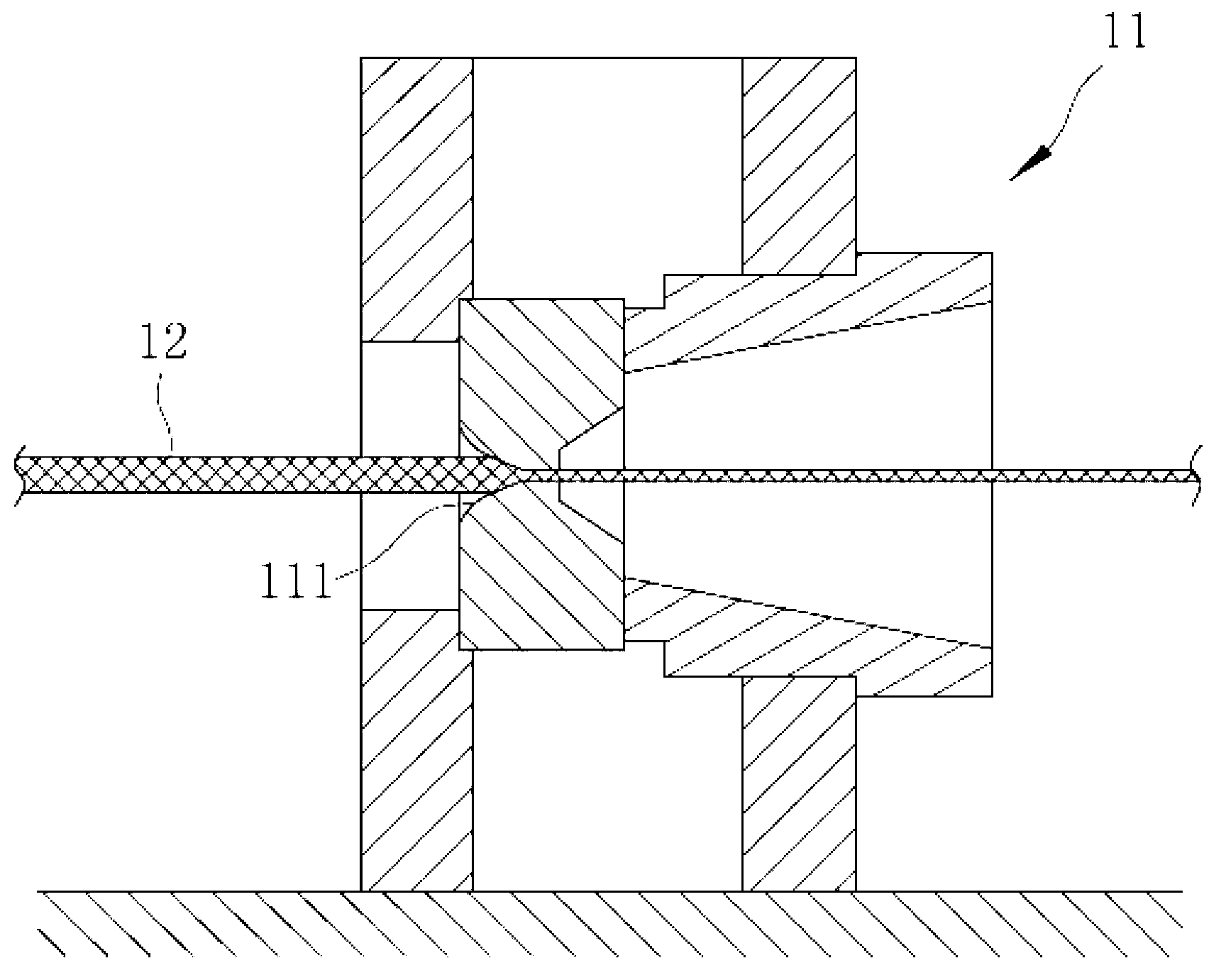

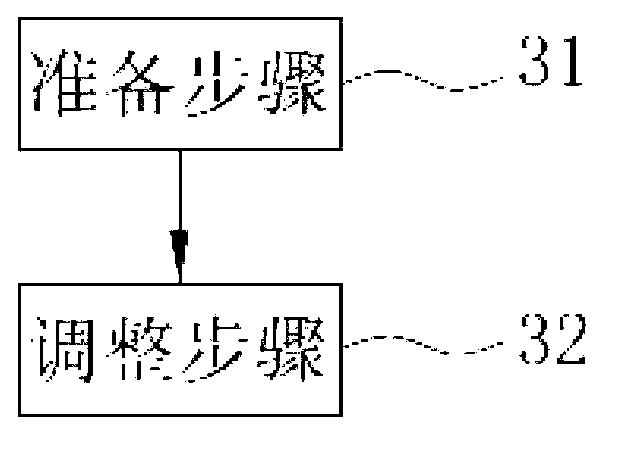

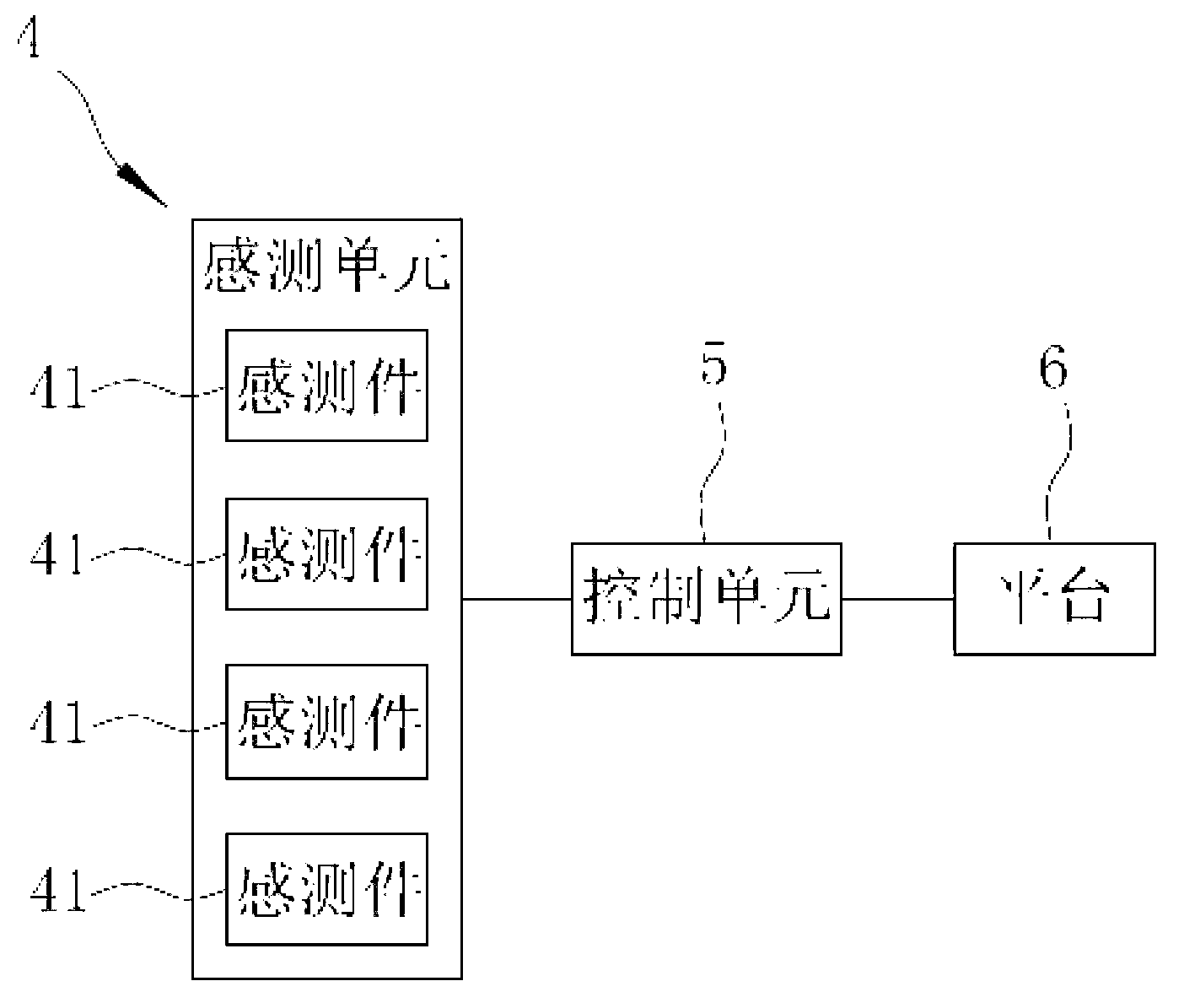

[0028] refer to figure 2 , is a preferred embodiment of the online automatic real-time centering method for cold drawing forming of the present invention, comprising a preparation step 31 and an adjustment step 32, and image 3 It is an online automatic real-time centering device for performing the above-mentioned centering method. Such as Figure 4 As shown, the above-mentioned centering method is used to detect the accuracy of drawing the wire 200 by a wire drawing module. The wire drawing module includes a feeder (not shown) that provides the wire 200, a The cold drawing machine 21 arranged at intervals, and a cold drawing die 22 arranged between the feeder and the cold drawing machine 21, the cold drawing die 22 has a perforation 221 for the wire 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com