Electronic scale type hydraulic carrying vehicle

An electronic scale and truck technology, applied in the direction of lifting device, etc., can solve the problems of large transmission noise of accessories, weak fastening force, uneven weighing of the weighing fork, etc., to reduce transmission noise, stable connection, weighing Heavy and accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Example 1

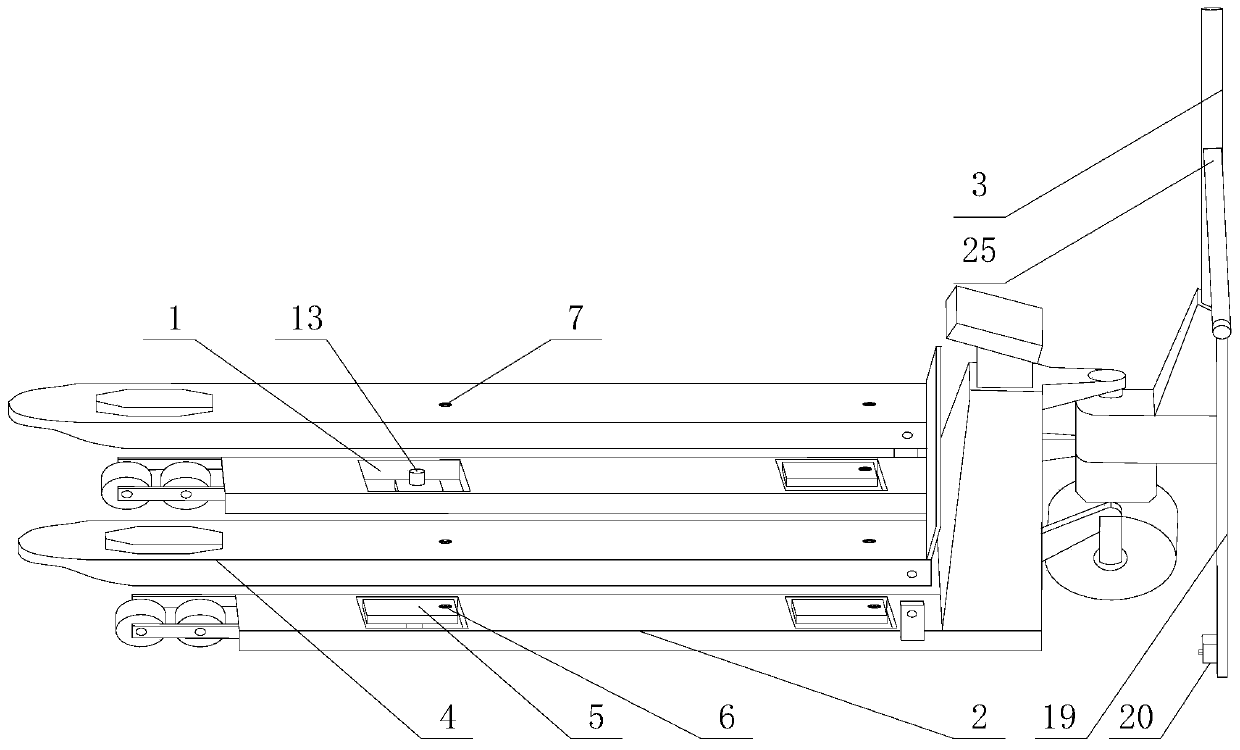

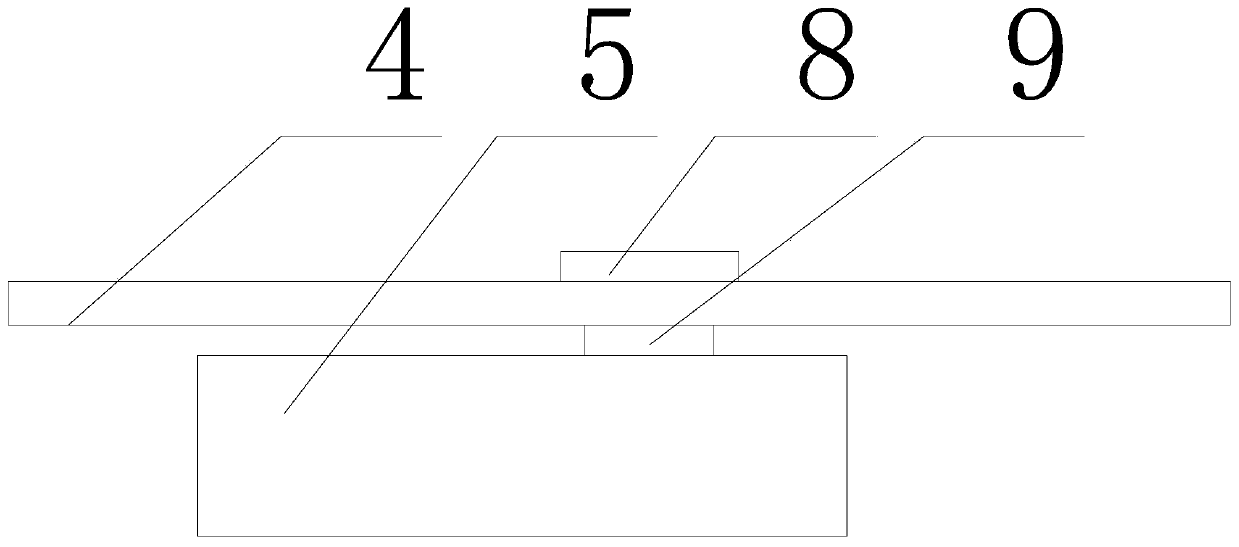

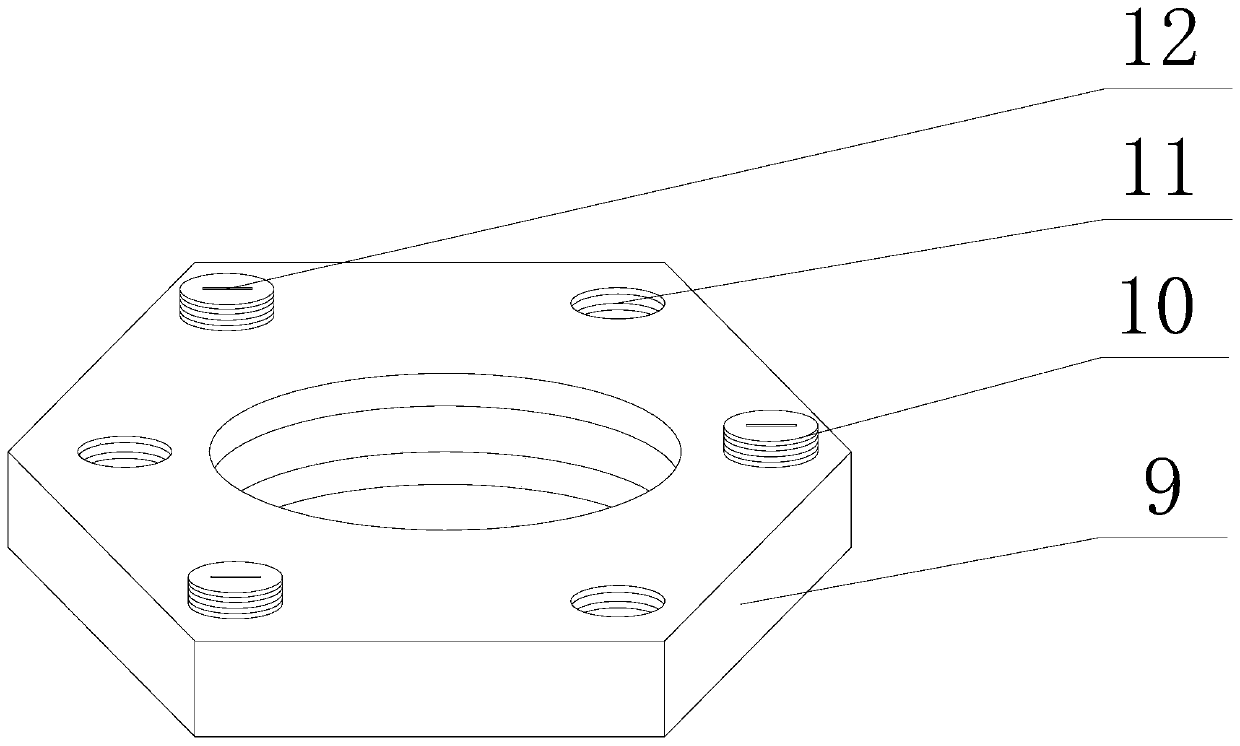

[0030] Such as Figure 1-Figure 3 As shown, this embodiment includes a frame 2, a weighing fork 4, and a plurality of limit bolts 8. The frame 2 is provided with a plurality of load cells 5, and the load cell 5 is provided with threads. Hole 6, the weighing fork 4 is provided with a plurality of first threaded holes 7, and the limit bolt 8 passes through the first threaded hole 7 and enters the threaded hole 6 to perform the weighing fork 4 and the load cell 5 Fastening, a nut 9 is arranged between the weighing fork 4 and the load cell 5, and the nut 9 is sleeved on the limit bolt 8. In this embodiment, there are four load cells 5, the frame 2 is a U-shaped frame, and two horizontal sections of the frame 2 are respectively provided with two load cells 5, in order to adjust the height of the ends of the fork 4. It can still be accurately adjusted when the height of the nut 9 is not an integer multiple of the height. In this embodiment, a plurality of threaded ...

Example Embodiment

[0031] Example 2

[0032] In order to enable the device to accurately weigh goods on a sloping ground, this embodiment is further limited on the basis of embodiment 1, such as Figure 4 As shown, in this embodiment, the frame 2 is a U-shaped frame, the weighing fork 4 has a U-shaped structure that matches the frame 2, and the front end of the weighing fork 4 is hinged on the frame 2, and Two blind holes 1 are respectively provided on the two horizontal sections of the frame 2. A load cell 5 is placed in each blind hole 1, and a cylinder 13 is provided in the blind hole 1 near the rear side of the horizontal section. The output terminal of 13 is hinged with the load cell 5. In this embodiment, protrusions are provided on the two horizontal sections of the frame 2, and the rotating shaft passes through the two protrusions and the weighing fork 4 to realize that the weighing fork 4 is hinged on the frame 2, in order to enable the staff to accurately Adjust the weighing fork 4 in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com