System and method for installing lifting rigging

A technology for hoisting slings and hoisting ropes, which is applied in the direction of transportation, packaging, and load hanging components, etc., which can solve the problems of high cost and complicated operation, and achieve the effects of easy operation, simple method, and no need for auxiliary cranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

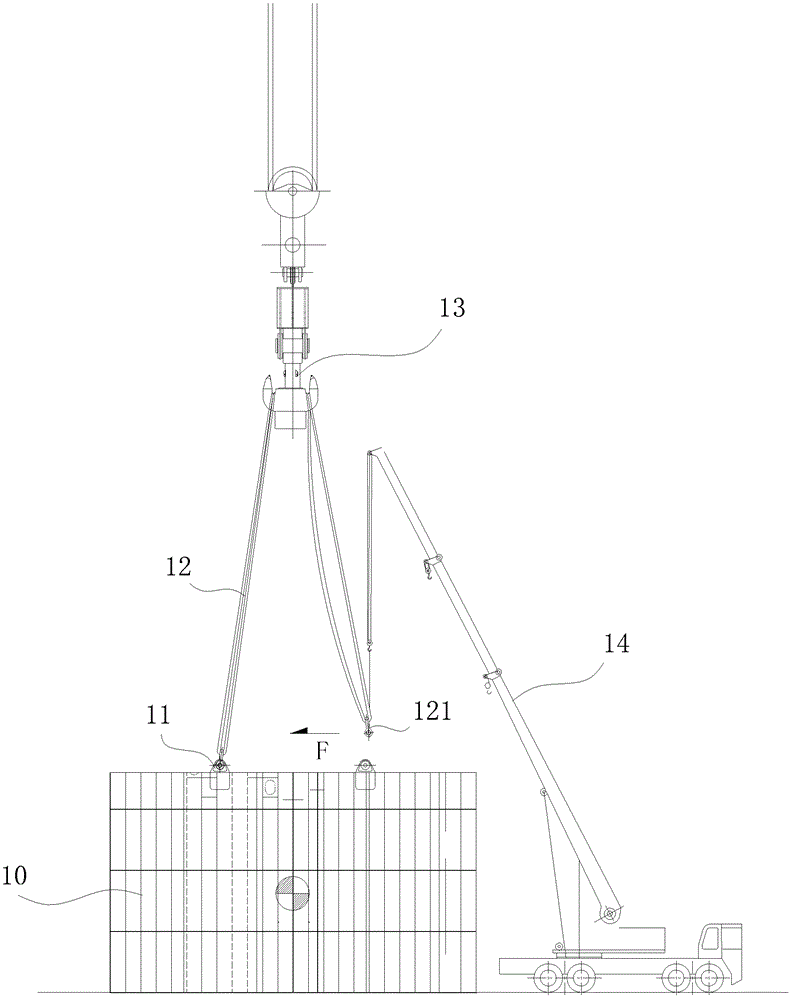

[0027] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments. In the following embodiments, the heavy-duty hoisting rigging and the column hoisting of a semi-submersible lifting platform are taken as an example (4 hoisting points are selected) to describe the tooling structure, system and method of the present invention in detail. However, it can be understood that this is not a limitation of the present invention, and the tooling structure, system and method of the present invention are also applicable to the installation of other hoisting slings, and the hoisting point of the suspended object is not limited to There are 4, and the distribution of its lifting points is not limited to symmetrical distribution. According to the structure of the actual suspended object, the number and distribution of its lifting points can be designed differently.

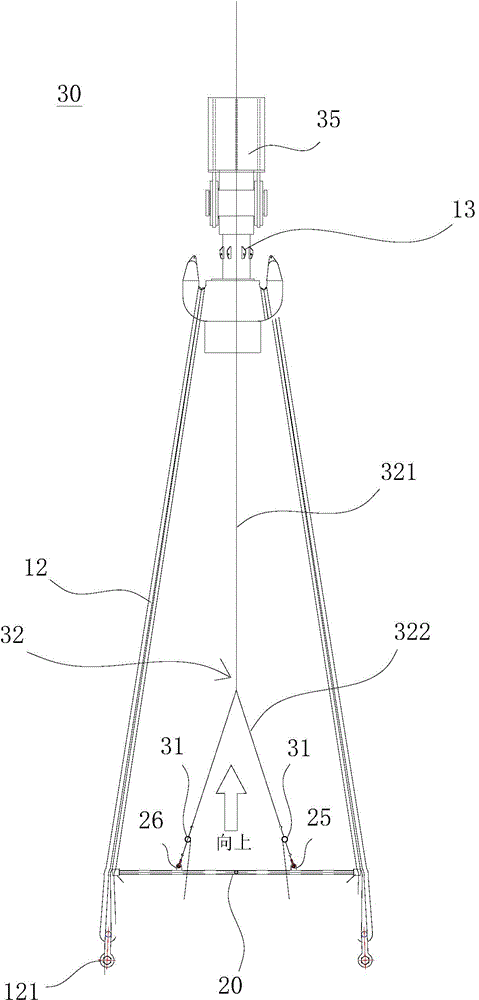

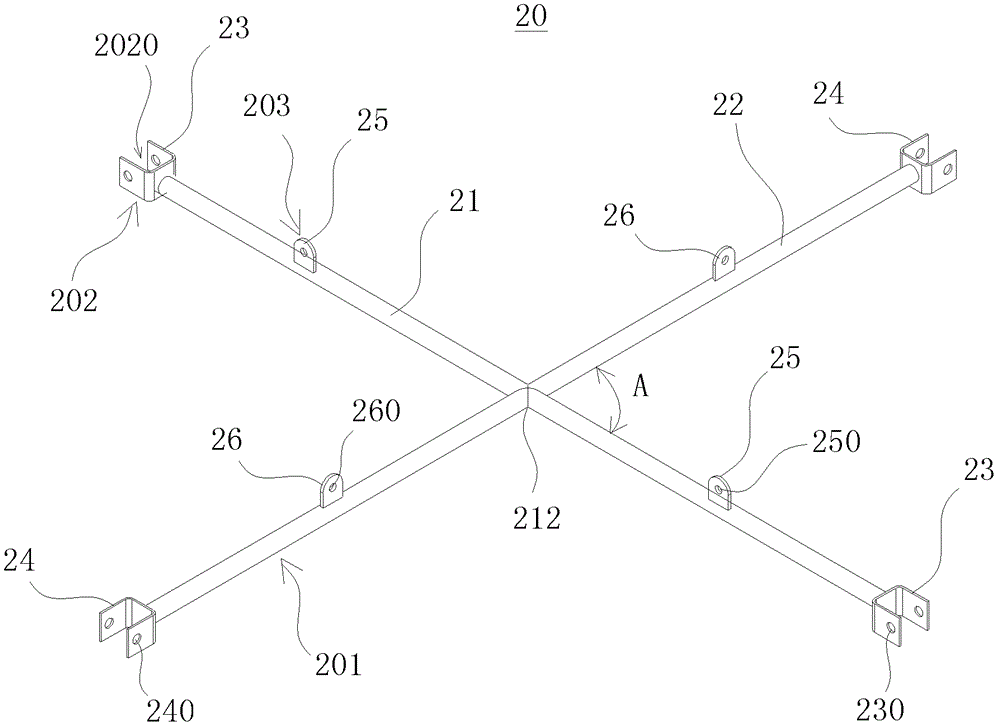

[0028] Such as Figure 2A As shown, the structure of a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com