Recycling method of polyolefin pipe containing hot melt adhesive

A technology of polyolefin and hot melt adhesive, which is applied in the field of power material recycling process, can solve the problems of not providing heat shrinkable sleeve recycling, etc., and achieve the effects of reducing cost risk, easy operation and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

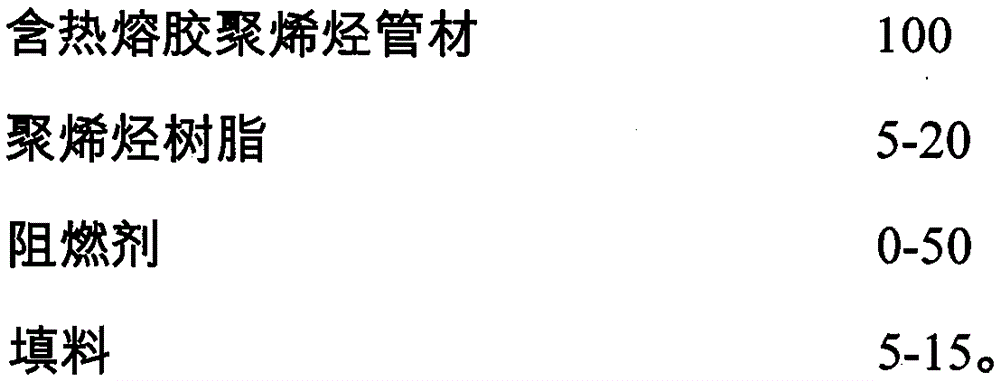

[0021] According to the ratio of parts by weight, including:

[0022]

Embodiment 2

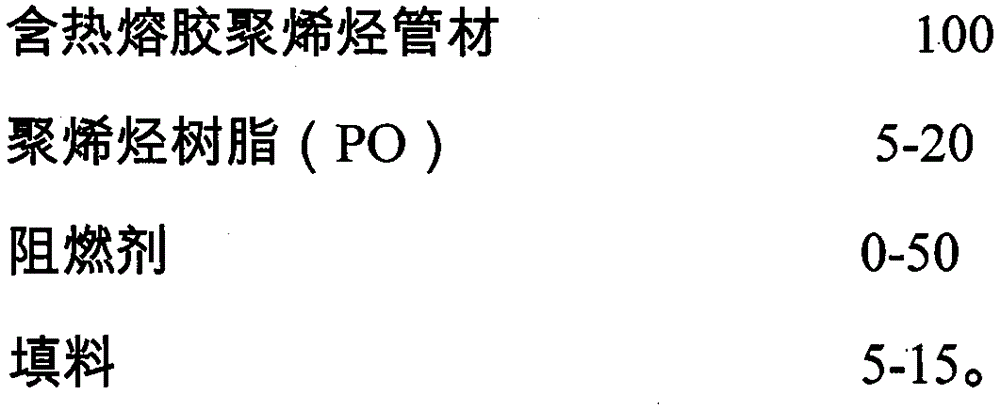

[0023] Embodiment 2: according to the ratio of parts by weight, including:

[0024]

Embodiment 3

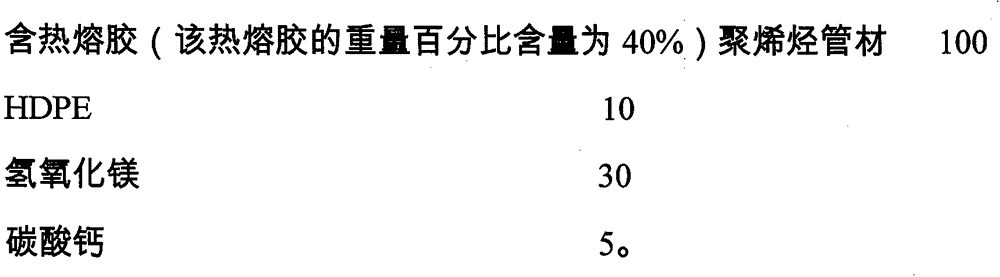

[0025] Embodiment 3: according to the ratio in parts by weight, including:

[0026]

[0027] The embodiment of the present invention provides a method for recycling polyolefin pipes containing hot melt adhesive, which is characterized in that it comprises the following steps:

[0028] Masterbatch processing steps: unirradiated recovered pipes containing hot-melt adhesive heat-shrinkable sleeves are compounded according to the components in the above-mentioned embodiment 1, 2 or 3, and re-granulated by a single-screw banburying extruder. That is: After the internal mixer is melted and blended at 100-150 ° C, the single-screw extruder is used to granulate;

[0029] Extrusion step: Add the recycled masterbatch obtained by the above method to the corresponding outer layer polyolefin masterbatch at a ratio of 0-15%. The added amount of the recycled masterbatch is not 0. After mechanical mixing, use a single Screw extruder (with corresponding die and mandrel) to extrude at 100-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com