Plane contact device used for rapidly conducting large current

A planar contact and high current technology, applied in the direction of contact parts, base/housing, etc., can solve the problems of poor contact electrical connection, poor connection stability, high temperature rise, etc., and achieve good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

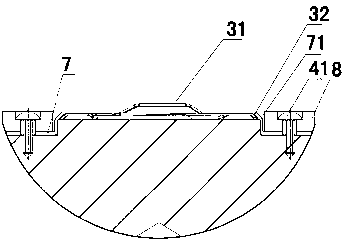

[0041] The invention discloses a touch-finger shockproof conductive device, such as Figure 1-Figure 3 As shown, there are first and second conductive bases that can communicate with each other, and the conductive surface 11 of the first base 1 is a plane. The base surface of the second base 2 is fixed with an elastic stamping conductive sheet, the elastic end of the elastic stamping conductive sheet protrudes from the second base surface, and the second base surface is provided with a device to avoid elastic stamping. The overpressure resisting surface of the conductive sheet, and the height of the resisting surface is lower than the elastic protruding surface of the elastic stamped conductive sheet, and the specific height is set according to the elastic stamped conductive sheet. When the first base 1 is pressed down, it touches the elastic stamping conductive piece, and the current is turned on. At this time, if it continues to press down, due to the blocking of the resisti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com