Forecasting method for loop length of hot continuous rolling mill

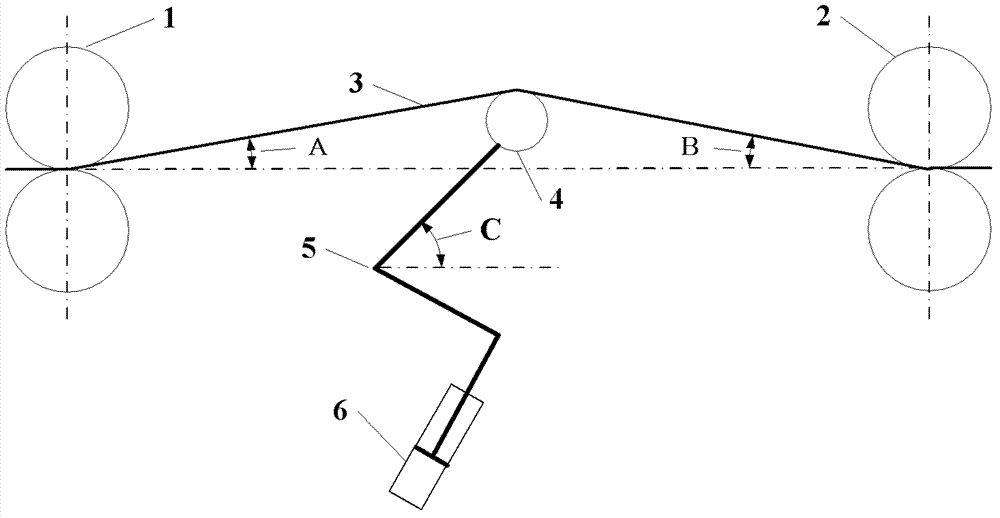

A hot continuous rolling mill and looper technology, which is applied in metal rolling, metal rolling, tension/pressure control, etc., can solve problems such as narrowing of the strip head, high looper tension, abnormal looper control, etc., and achieve Stabilize the wearing of the belt, avoid the effect of pulling up and narrowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

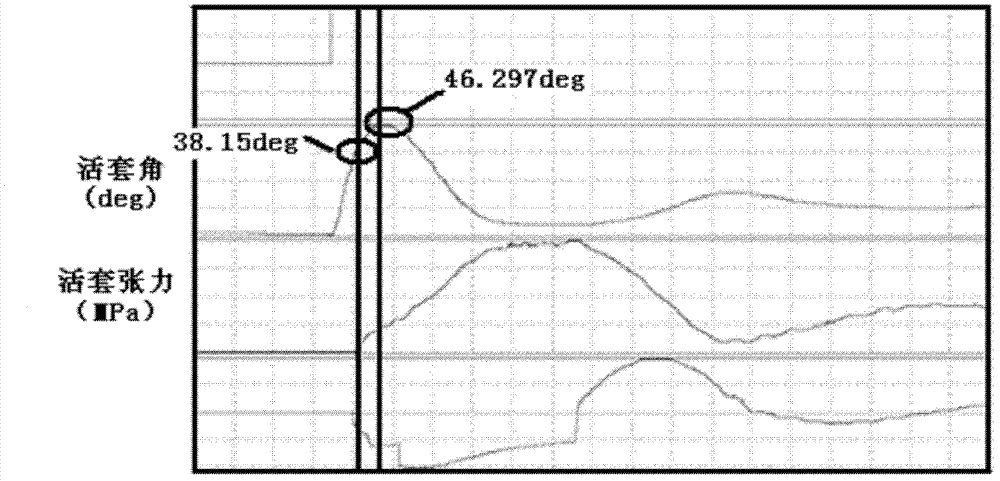

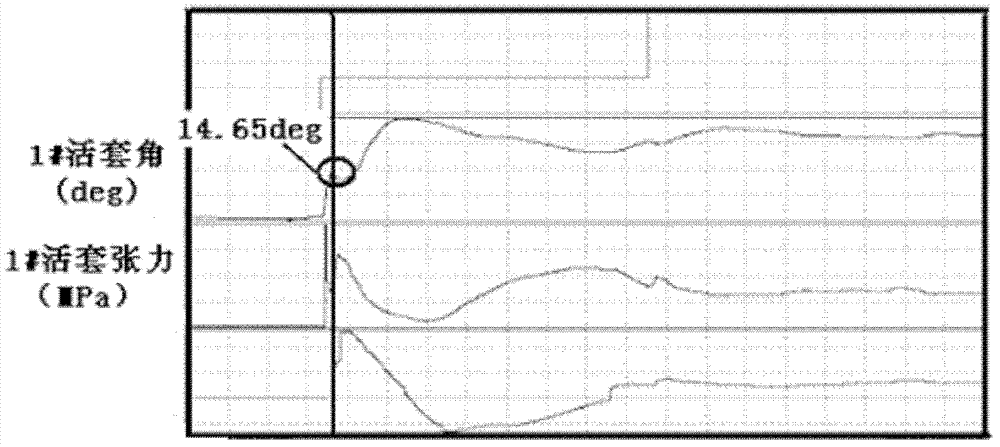

[0031] Such as Figure 4 As shown, obtain the cover quantity coefficient of six loopers on the hot continuous rolling mill according to the following steps (in the present embodiment, the strip steel is ordinary carbon steel, and the thickness is 3.0mm):

[0032] (1) Determine the set amount LOOP1 of the six loops between the hot rolling mill stands at the moment of strip steel bite j , the calculation results are shown in Table 1:

[0033] LOOP 1 j = 1 2 · V 1 j · t j - - - ( 1 )

[0034] In formula (1), V 1j When the steel strip is bitten, the speed drop value of the hot rolling mill stand corresponding to the jth looper (when the strip steel bites, the speed of the stand is impacted,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com