Synchronous rotating mechanism for shuttle race

A technology of synchronous rotation and shuttle bed, applied in the direction of sewing machine ring mechanism, sewing machine components, sewing machine needle seat, etc., can solve the problems of not meeting the requirements, low product pass rate, affecting the overall quality of the product, etc., to improve the appearance Aesthetics, wide use value, effect of improving sewing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following best examples of the shuttle bed synchronous rotation mechanism of the present invention do not limit the protection scope of the present invention.

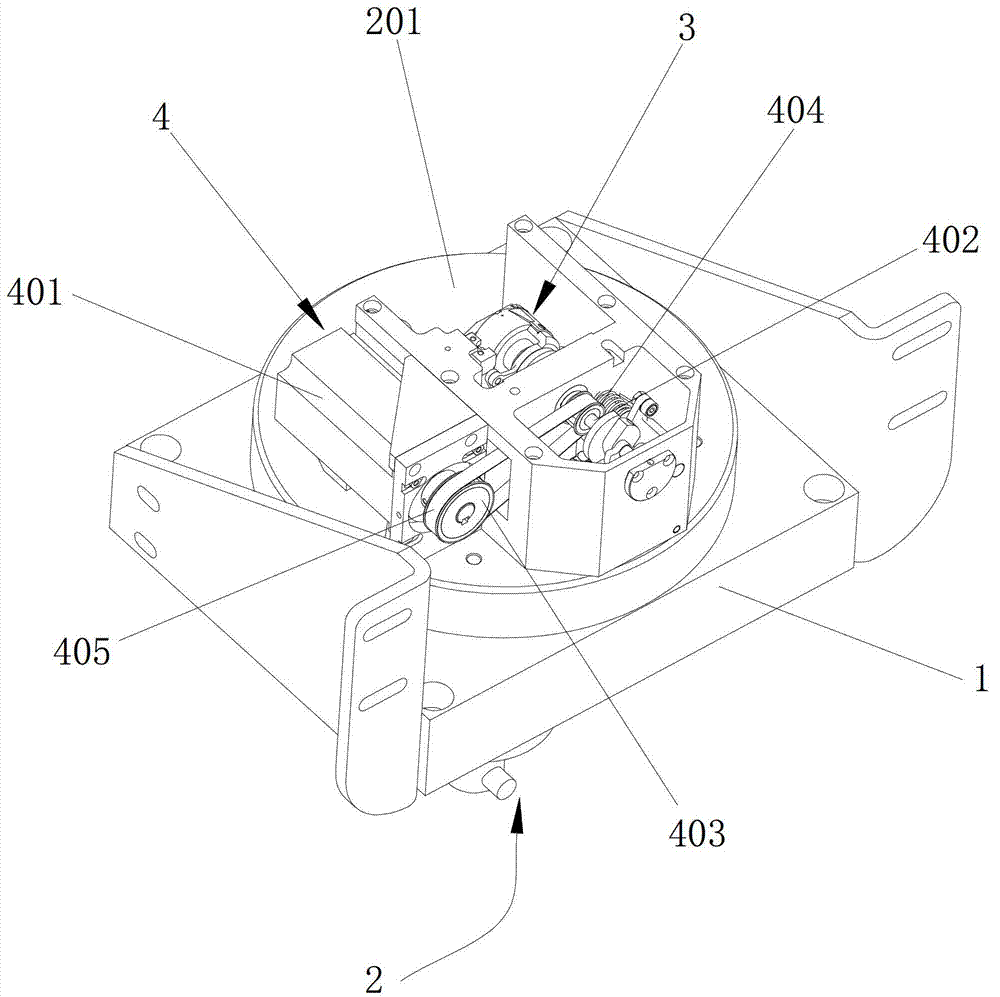

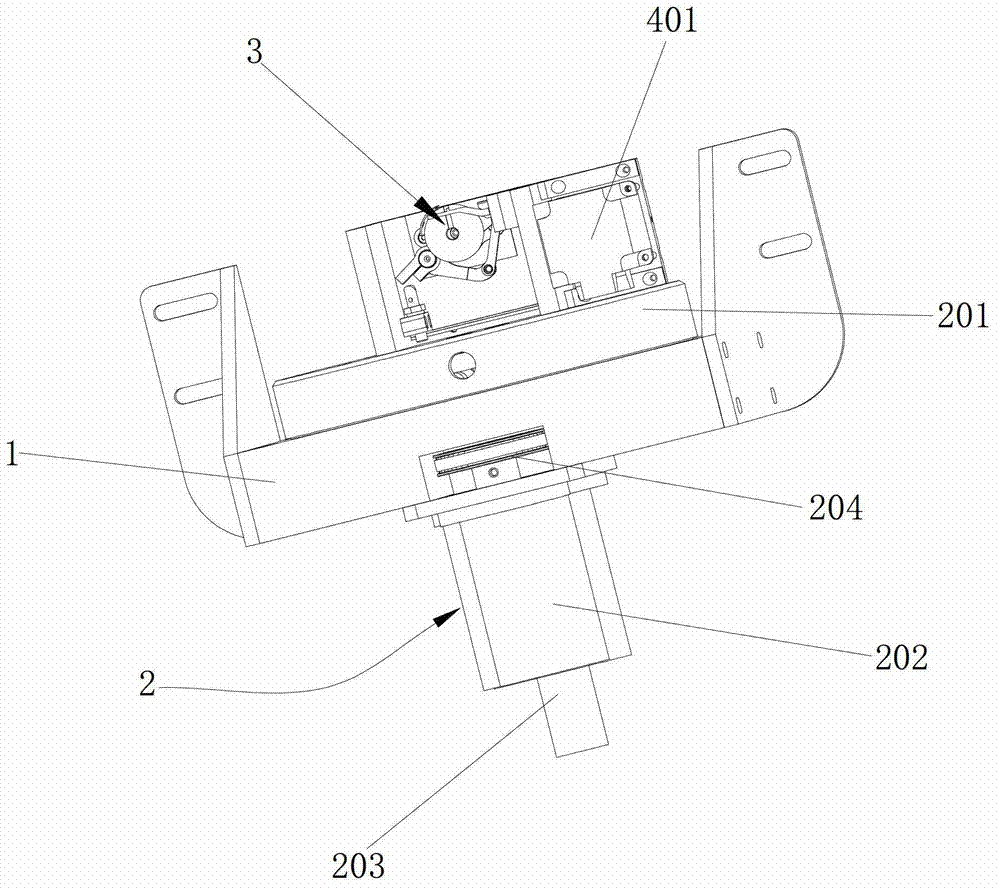

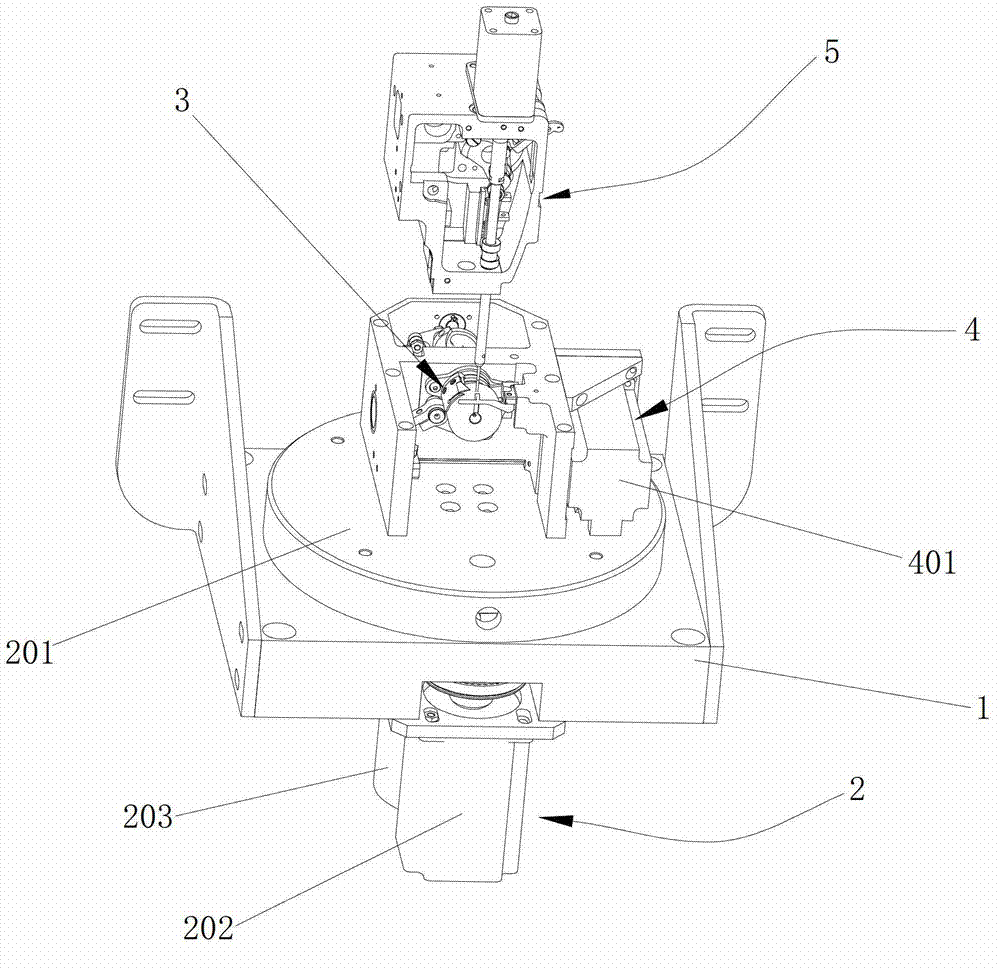

[0016] refer to figure 1 , figure 2 , image 3 , Figure 4 , providing a shuttle bed synchronous rotation mechanism, including a base 1, a rotating device 2 mounted on the base 1, a shuttle bed 3 mounted on the rotating device 2 and capable of rotating with the rotating device 2, and a shuttle bed driving mechanism 4. The shuttle bed drive mechanism 4 is in transmission connection with the shuttle bed 3 . By installing the shuttle bed driving mechanism 4 and the shuttle bed 3 on the rotating device 2, the rotating device 2 can drive the shuttle bed driving mechanism 4 and the shuttle bed 3 to rotate simultaneously, thereby realizing the shuttle bed 3 during sewing. Adaptive rotation can be carried out according to the stitch direction, so as to adjust the angle of the shuttle bed 3 to adapt to the set s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com