Method for designing salt rock stratum irregular-shaped sleeve

A casing design and casing technology, applied in the direction of casing, drill pipe, drilling equipment, etc., can solve the problems of reducing effective stress, insufficient strength, and failure to ensure that thick-walled casing remains intact, and achieve the effect of reducing effective stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Further illustrate the present invention according to accompanying drawing below.

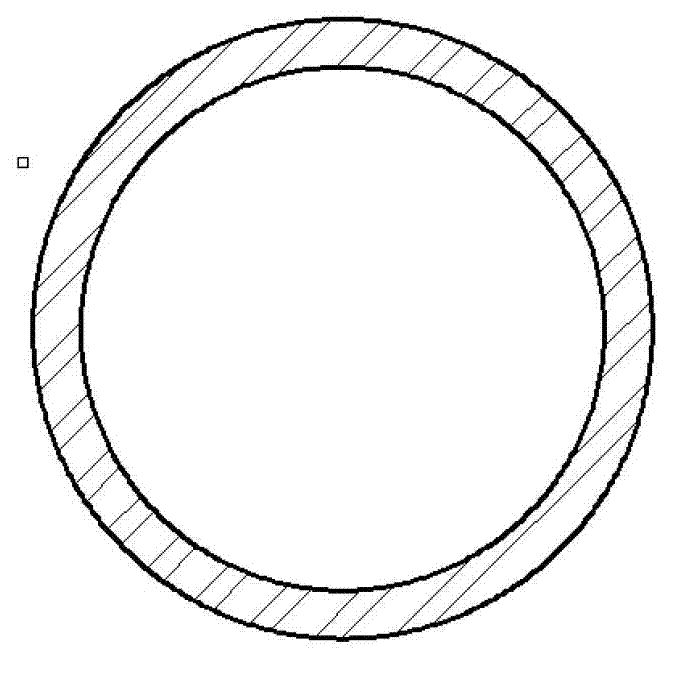

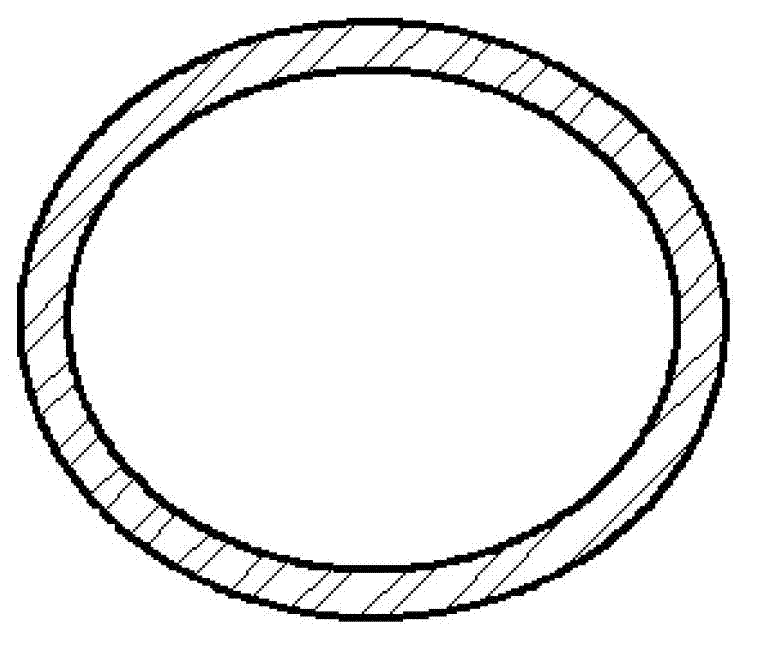

[0055] see figure 1 , figure 2 . figure 1 , figure 2 It is the cross-sectional view of conventional thick-walled casing before and after deformation. According to the drilling conditions and logging data of the corresponding block and its adjacent wells, the stress state of the salt rock formation of the well is determined, and the maximum and minimum principal stresses and ground stresses of the interval are calculated. Non-uniformity of stress.

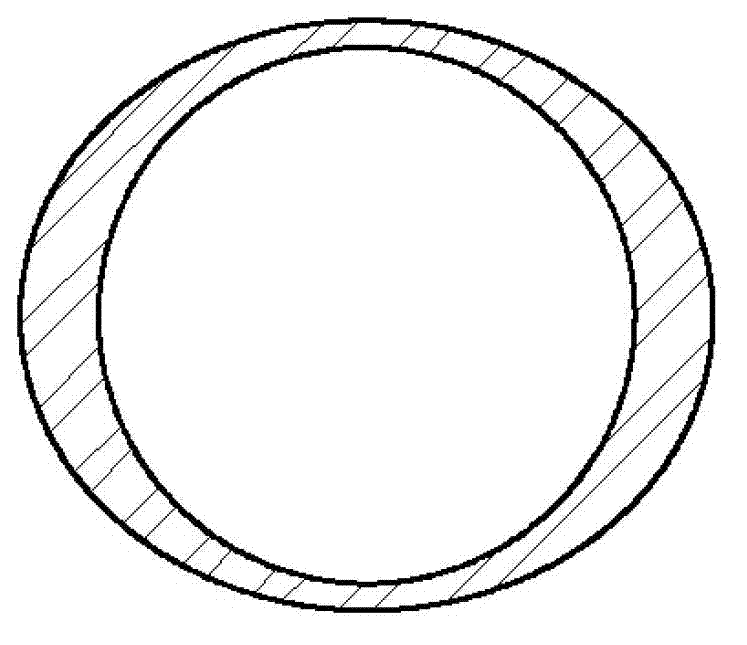

[0056] The special-shaped casing designed by the present invention has the following two forms: the inner wall of the casing is circular, and the outer wall is oval (see image 3 ); the inner wall of the casing is oval and the outer wall is circular (see Figure 4 ). Apply the ground stress load and a time-varying creep load to the two special-shaped casings, the effect of the application is as follows Figure 5 , Figure 6 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com