Parameter determination method for bolt supporting based on roadway bearing structure

A load-bearing structure and bolt support technology, which is applied to the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of lack of scientific and economic rationality, ambiguity and uncertainty of determination methods, and operability Insufficient and other problems, to achieve the effect of shortening the roadway design cycle, extensive practicability, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

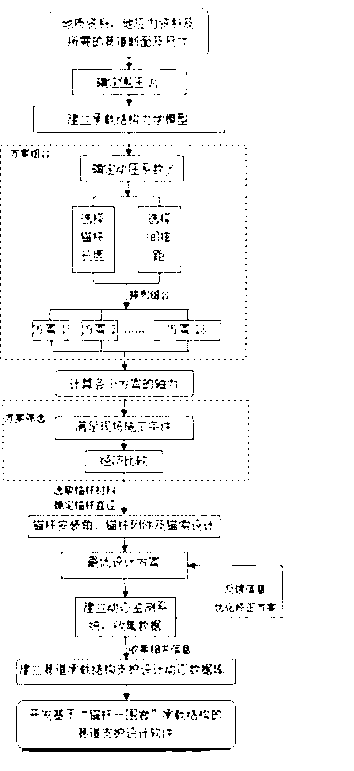

[0034] The bolt support parameter determination method based on roadway bearing structure of the present invention comprises the following steps:

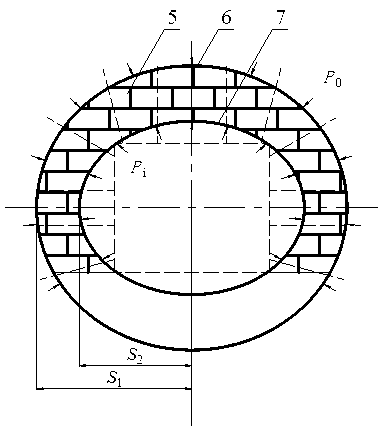

[0035] (1) According to the physical and mechanical properties, occurrence conditions and in-situ stress conditions of the surrounding rock of the roadway, the confining pressure of the surrounding rock of the roadway is obtained P 0 ;

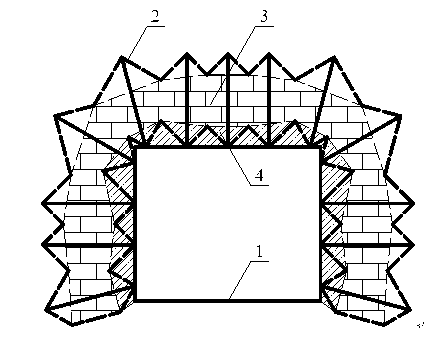

[0036] (2) According to the required section shape and size of the roadway, the stress state of the surrounding rock and the actual engineering situation, establish a mechanical model of the load-bearing structure;

[0037] (3) Determine different support schemes and calculate the corresponding anchor bolt axial force:

[0038] a According to the roadway position, take the dynamic pressure coefficient f The value ranges from 1 to 3. When the roadway is not affected by mining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com