Spherical surface coloring and contact area detecting device

A technology of inspection device and contact area, applied in the field of mechanical transmission, can solve the problems of large interference, narrow spherical surface in the cage, unsuitable for measurement, error, etc., to achieve the effect of improving accuracy, assembly quality and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

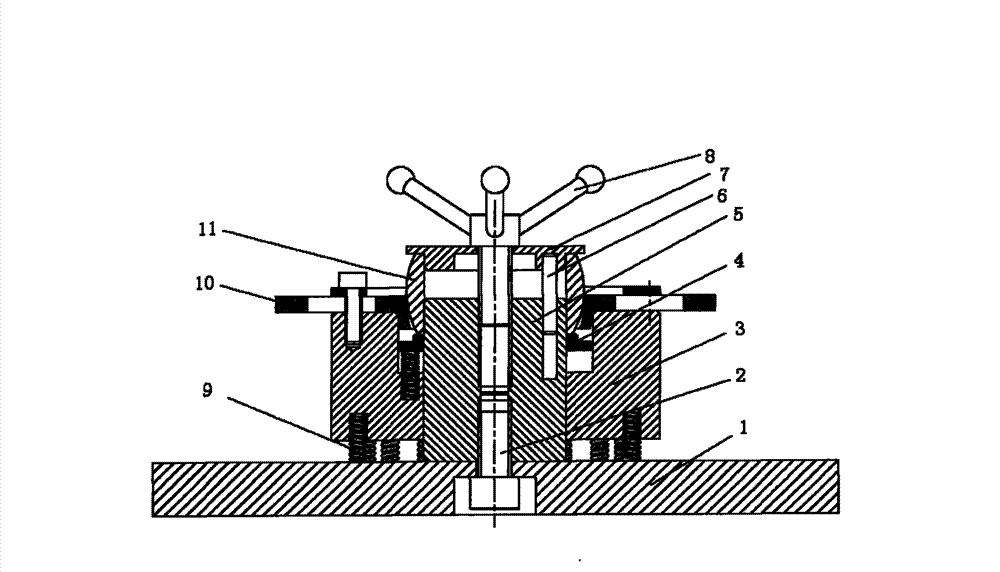

[0011] The invention relates to a spherical surface coloring and contact area inspection device, which is a guiding and positioning device for placing a cage and a ball bowl. Its implementation is as figure 1 As shown, the bottom plate 1 in the mechanism is used as the basis for supporting and fixing the whole device, so the guide device of the ball bowl, that is, the guide cylinder 5, can be fixed on the base plate 1 by fastening the bolt 2, and the base 3 is then sleeved on the guide cylinder 5 and fixed on the bottom plate 1. Maintain a high coaxiality, the coaxiality requirement is less than Φ0.01; and the spring 9 is used to support the base 3, which has two functions, one is to prevent the ball bowl 11 and the cage 10 from contacting the base 3 and The impact caused by the hard contact of the base plate 1 causes damage to the surface of the ball b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com