Methods of Attaching and Dismounting Using Temporary Suspension Elements

A component, suspension technology, applied in fixtures, metal processing equipment, metal processing, etc., can solve the problems of operator danger, tilt or fall, bulky, etc., to achieve the effect of low price, increase time or cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

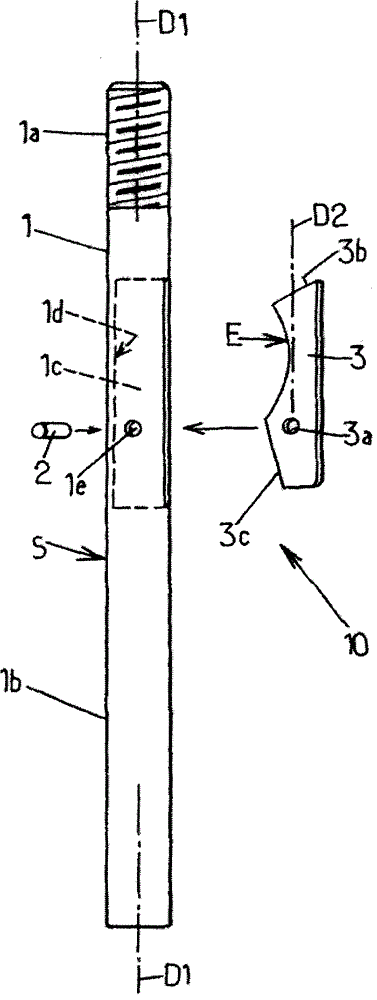

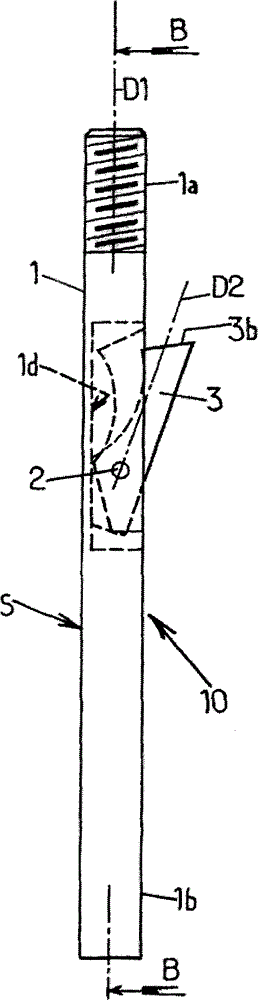

[0045] exist figure 1 Among them, the temporary suspension element 10 includes a linear guide 1 , a cross pin 2 and a hook 3 .

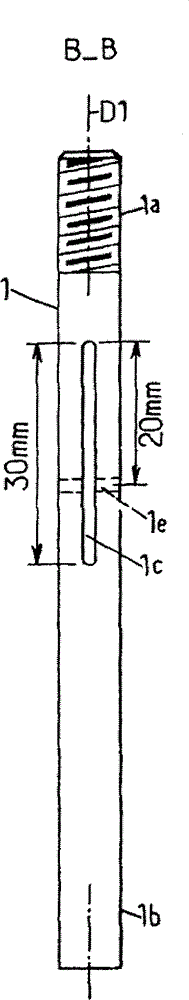

[0046] The linear guide 1 comprises a threaded end 1a and a cavity 1c at a distance from the thread of the end 1a. from Figure 2b As can be seen in , the cavity 1 c may be shaped as a slot within the width of the guide 1 . D1 denotes the longitudinal direction of the linear guide 1 . The outer surface S of the guide 1 is smooth and parallel to the direction D1 so as to form a sliding surface apart from the threaded end 1a and the cavity 1c. The guiding device 1 can be made of a cylindrical rod, such as a metal rod.

[0047]Optionally, the linear guide 1 can have a clamping end 1b opposite to the end 1a in the direction D1, the length of the end 1b from the cross pin 2 being greater than 50 mm (millimeters). The clamping end 1b can be round or conical in order to facilitate its introduction into the hole of the outer structure.

[0048] As an e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com