Solar cell system capable of automatically removing dust

A technology for solar cells and automatic dust removal, applied to circuits, electrical components, cleaning methods using tools, etc., can solve the problems of dust accumulation and inability to effectively clean the dust on the surface of solar cells, avoid accumulation, improve dust removal effect, and simplify mechanical effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

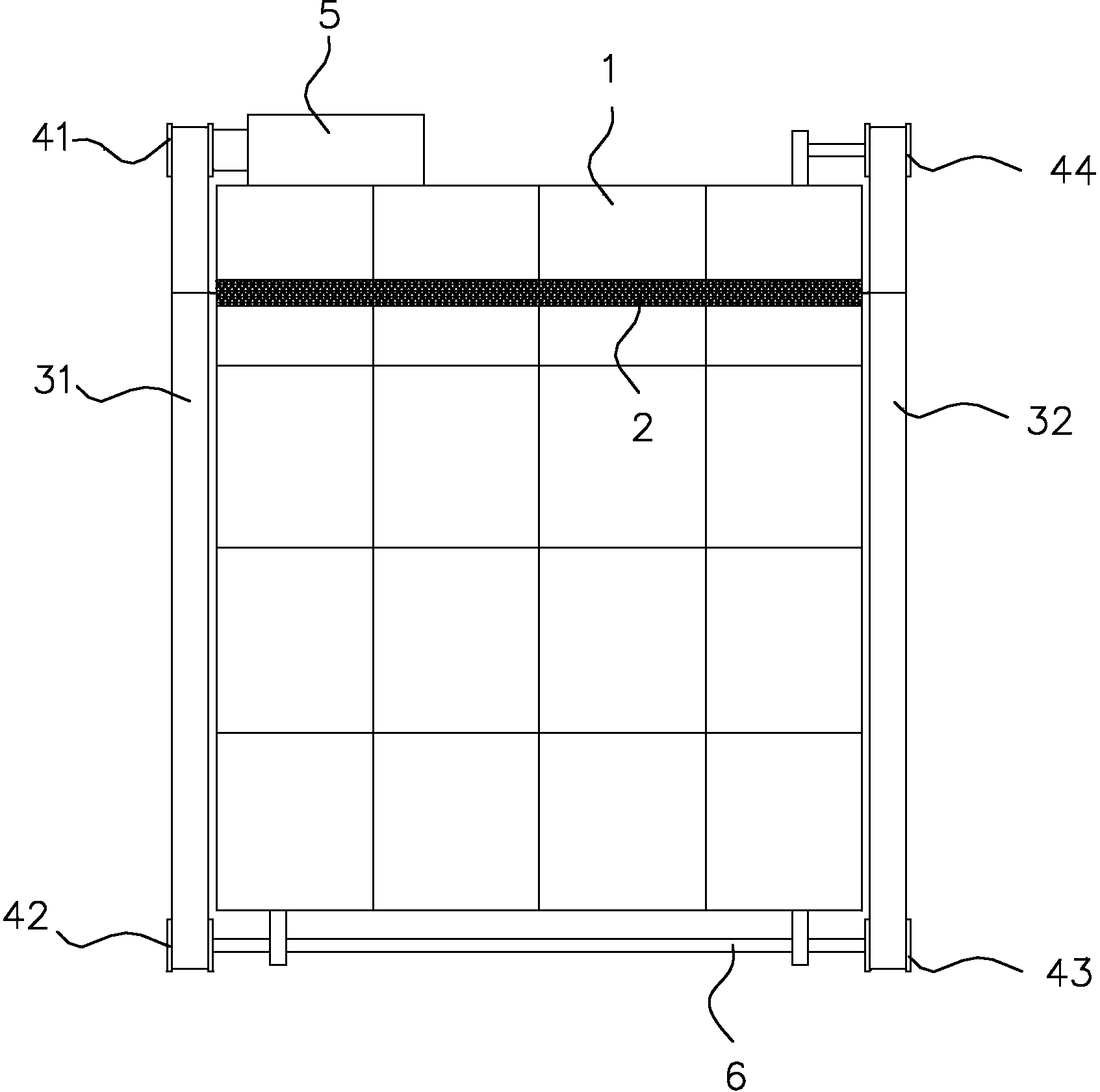

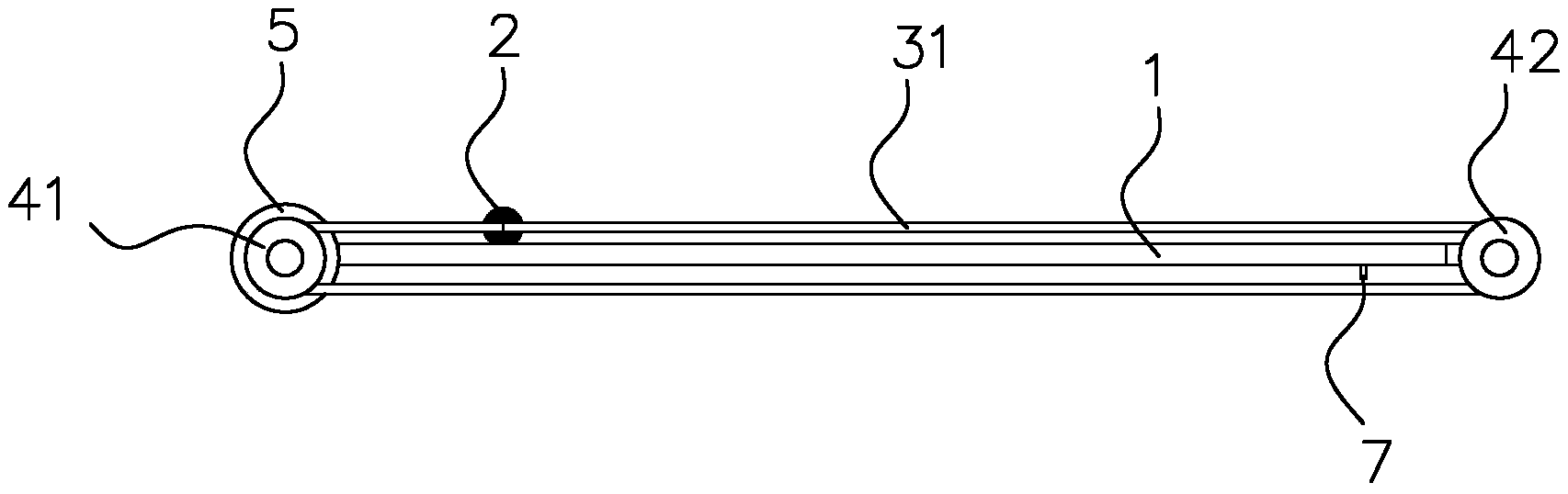

[0030] like figure 1 and 2 As shown, the solar battery system of this embodiment includes a solar photovoltaic panel 1 , a dust removal brush 2 , two conveyor belts, four supporting wheels and a driving motor 5 .

[0031] like figure 1 As shown, a driving motor 5 is fixed on the top edge of the solar photovoltaic panel 1, and four supporting wheels are symmetrically distributed on the outside of the four corners of the solar photovoltaic panel 1, wherein the supporting wheel 41 is coaxial with the supporting wheel 44, and the supporting wheel 42 is coaxial with the supporting wheel 43 coaxial.

[0032] The supporting wheel 41 is connected with the driving motor 5; two guide blocks are arranged on the lower edge of the solar photovoltaic panel 1, and coaxial through holes are arranged on the two guide blocks, and a rotating rod 6 passes through the through holes on the two guide blocks , is connected to the solar photovoltaic panel 1 in rotation, the support wheel 42 and the...

Embodiment 2

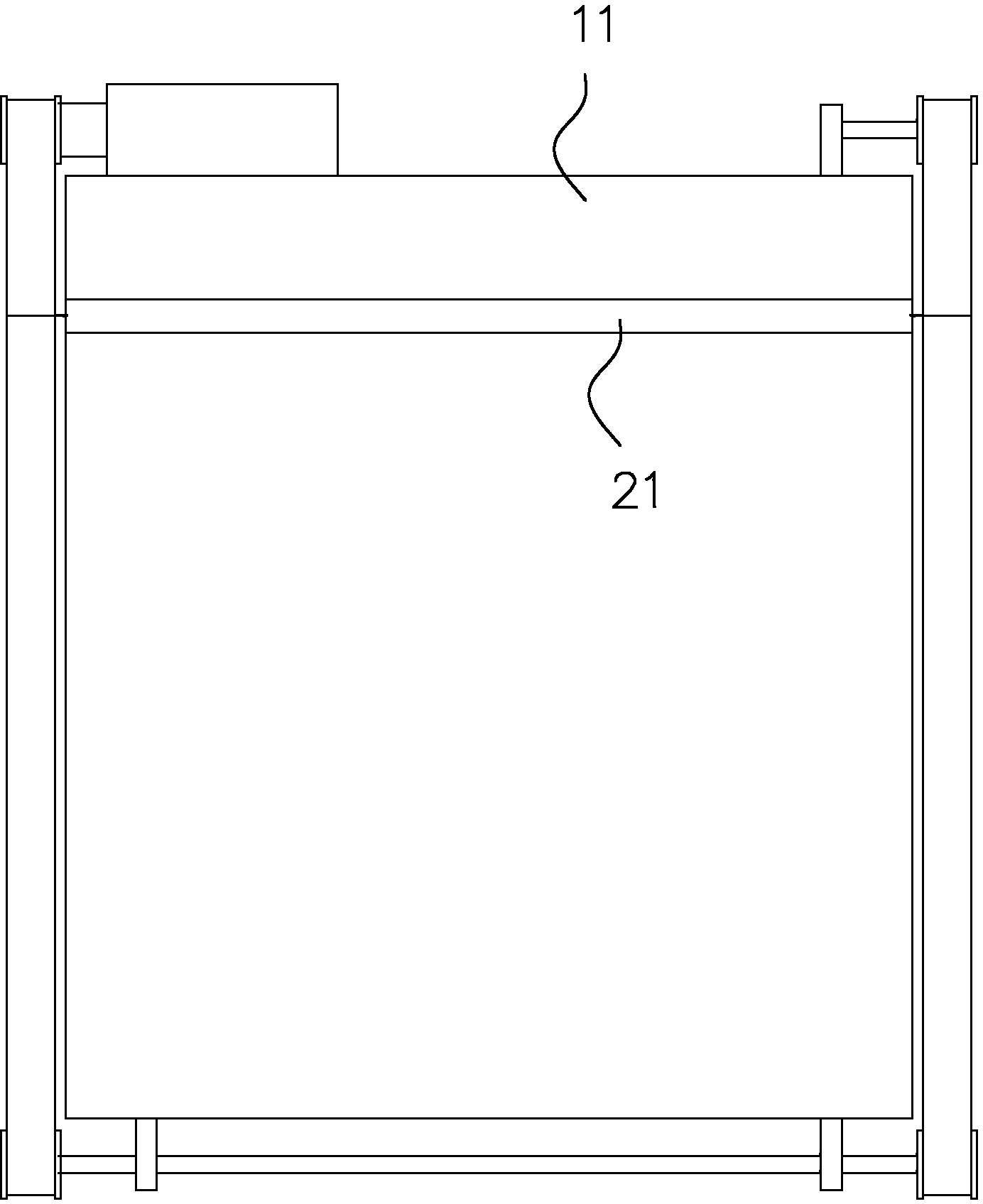

[0047] like image 3 and 4 As shown, the solar battery system of this embodiment includes a solar photovoltaic panel 11, a dust removal brush 21, two conveyor belts, four supporting wheels and a driving motor. Wherein except that the dust removal brush 21 and the solar photovoltaic panel 11 are different from the first embodiment, other structures are the same as the first embodiment.

[0048] The solar photovoltaic panel 11 has a smooth surface, and the dust removal brush 21 is a strip-shaped scraper. The friction force between the panels 11, and the slope generated by the chamfering is attached to the front of the solar panel 11.

[0049] During work, the surface of the dust removal brush 21 is seamlessly attached to the front of the solar battery panel 11, and the dust removal effect is better.

[0050] To sum up, in Embodiment 1 and Embodiment 2, the movement trajectories of the dust removal brush 2 and the dust removal brush 21 are circular, and the accumulated dust ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com