Improved rock sliver conveying device

A technology of conveying device and rock wool strips, which is applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of easy wear and tear of polished rods, and achieve the effects of being convenient for widespread application, avoiding the replacement of polished rods, and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

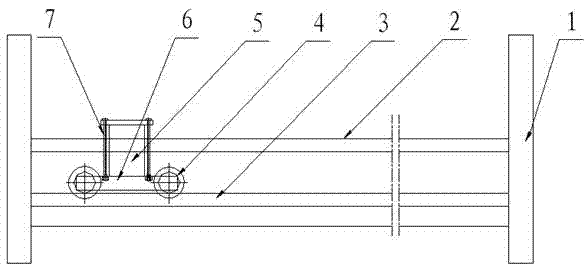

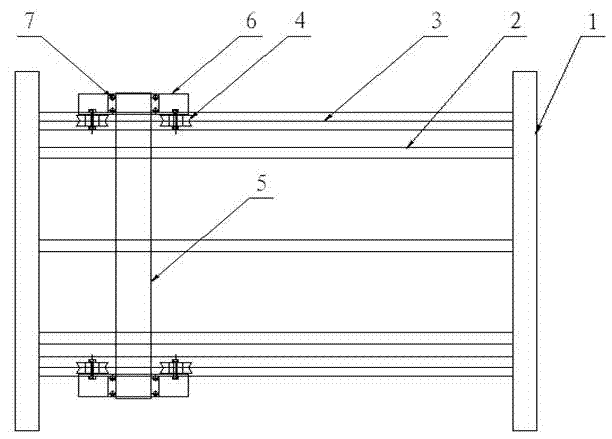

[0016] The drawings show a specific embodiment of the invention. This embodiment includes a bracket 1, a number of guiding polished rods 2 fixed on the bracket 1, and a rock wool conveying rack 5 placed on the guiding polished rod 2. The bracket 1 is provided with two angle steel rails 3 parallel to the guiding polished rod 2. The rail 3 is provided with triangular rollers 4, and the rock wool conveying rack 5 is installed on the rollers 4 through a roller connecting frame 6 at both ends; the rock wool conveying rack 5 has two rollers 4 at both ends, and two The center distance of each roller 4 is 300 mm; the roller connecting frame 6 is fixed to the rock wool conveying frame 5 by connecting bolts 7.

[0017] The bracket 1 plays a role of fixing and supporting, the guiding polished rod 2 and the angle steel rail 3 are fixed on the bracket, the roller 4 is fixed on the rock wool conveying frame 5 by the connecting bolt 7, and the rock wool conveying frame 5 and the roller 4 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com