Paving brick laying machine

A laying machine and paving brick technology, which is applied in the field of construction machinery, can solve the problems of poor pavement adaptability, poor traveling accuracy, and inability to swing the laying mechanism, so as to ensure the laying accuracy and improve the pavement adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

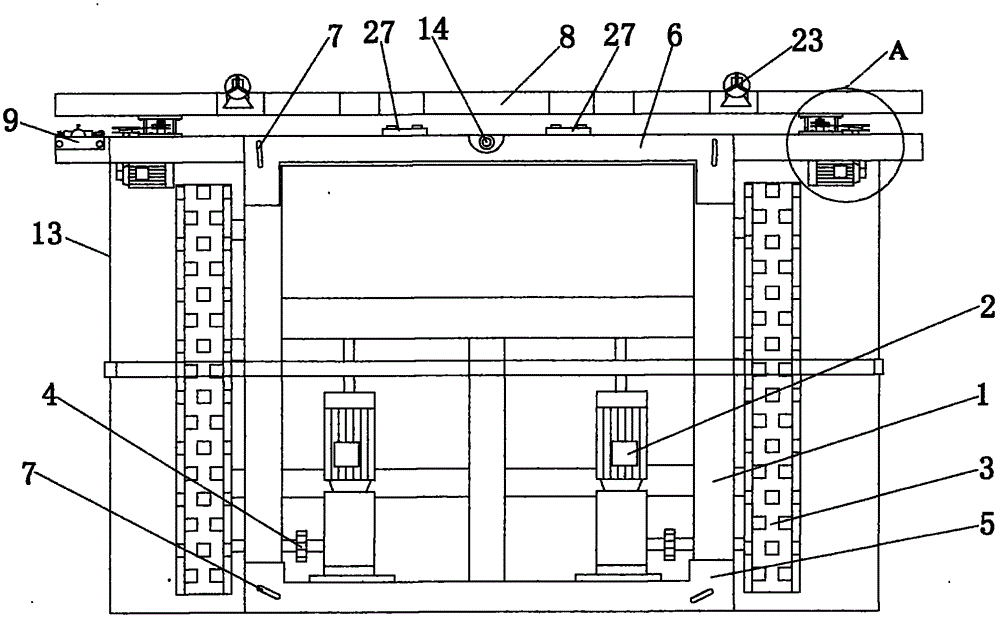

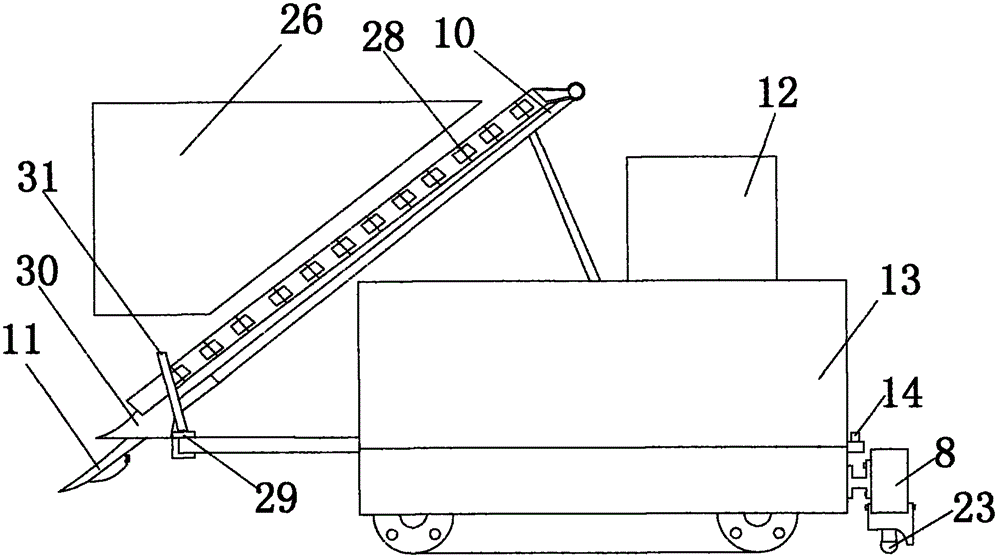

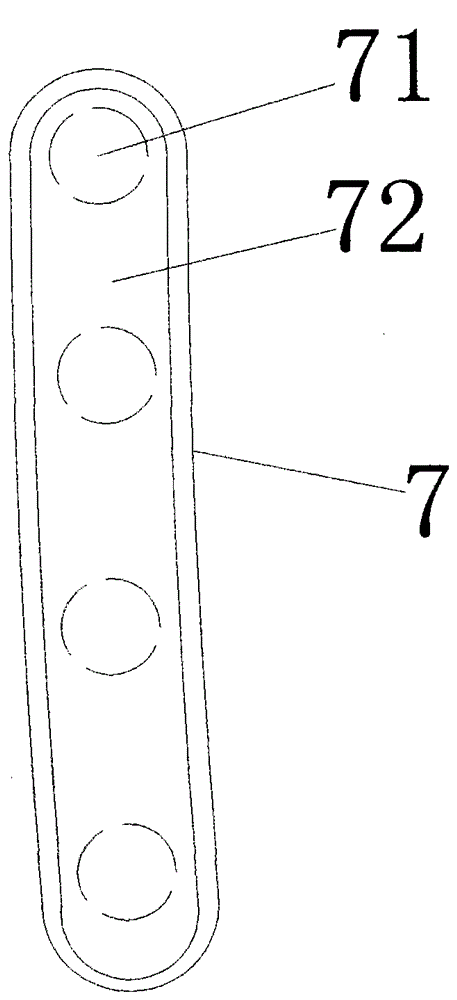

[0019] A paving brick laying machine, mainly composed of a chassis frame 1, track wheels 3, a laying platform 13 and a controller 12, a brick bucket 26 is arranged on the laying platform 13, and an inclined sliding brick board 10 is arranged below the brick bucket 26, and the sliding brick board 10 is connected to the guide plate 11, and the rear end of the chassis frame 1 is connected to the leveling device 8, and the two ends of the leveling device 8 are provided with track wheels 23, and two parallel reduction units 2 are arranged on the chassis frame 1, and the two reduction units 2 pass through the gear transmission mechanism 3 independently drive the left and right track wheels 3 to move, the front end of the chassis frame 1 is provided with two front swinging slides 5, the rear end of the chassis frame 1 is provided with two rear swinging slides 6, and the front swinging slides 5 and the rear swinging slides 6 are respectively provided with two arcs. Shaped groove 7, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com