Adjustable ballastless track self-compacting concrete pouring composite formwork

A self-compacting concrete, ballastless track technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of poor pouring quality, waste cleaning, poor accuracy, etc., to improve quality, facilitate construction, and improve the effect of plumpness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

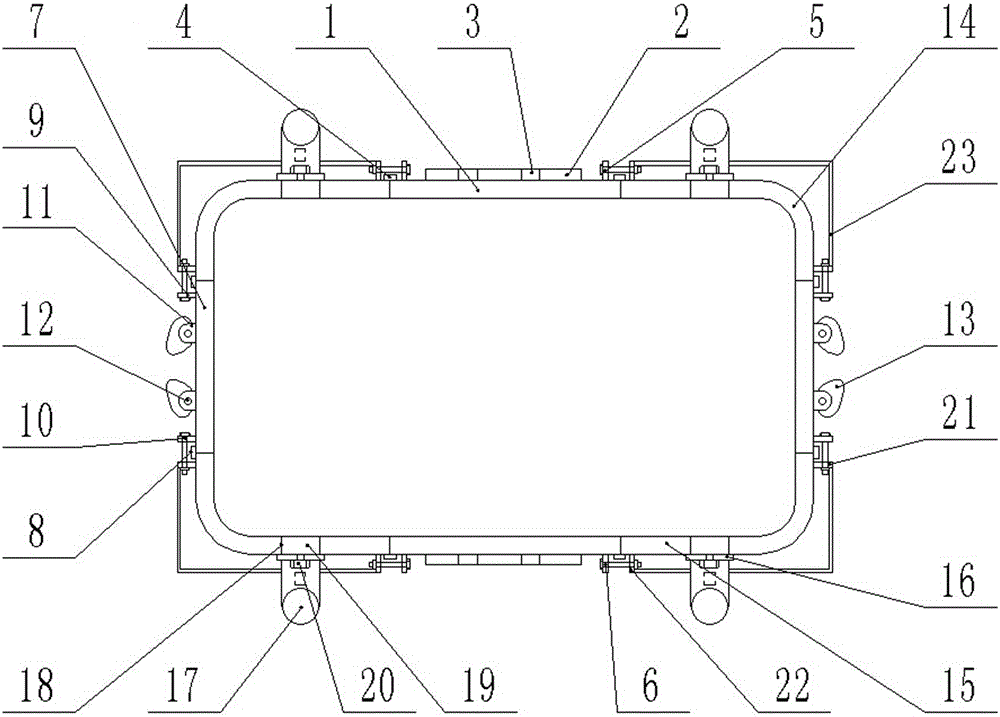

[0014] Adjustable ballastless track self-compacting concrete pouring combined formwork, including longitudinal formwork, transverse formwork, corner formwork spliced with the longitudinal formwork and transverse formwork and matched with the corner of the track slab;

[0015] The longitudinal formwork includes a formwork body 1, the outer end surface of the formwork body 1 is provided with horizontal reinforcing ribs 2 and longitudinal reinforcement ribs 3, and the left and right ends of the outer end surface of the formwork body 1 are fixed with crimping plates 4 protruding from its ends, the formwork body 1 The outer end surface is fixed with a connecting end plate 5 perpendicular to it and located inside the crimping plate 4, and a bolt connection hole 6 is opened on the connecting end plate 5;

[0016] The horizontal template includes a template body I7, the left and right ends of the outer end surface of the template body I7 are fixed with a crimping plate I8 protruding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com