Lifting Method of Balanced Ballast at Four Corners of Leveling Ship

A technology of leveling boat and four corners is applied in the field of equalized ballast lifting of four corners of leveling boats, which can solve the problems of difficulty in ensuring the stability of the hull platform and the safety of the laying precision of the foundation bed, and achieves the guarantee of laying precision, high work efficiency and time saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

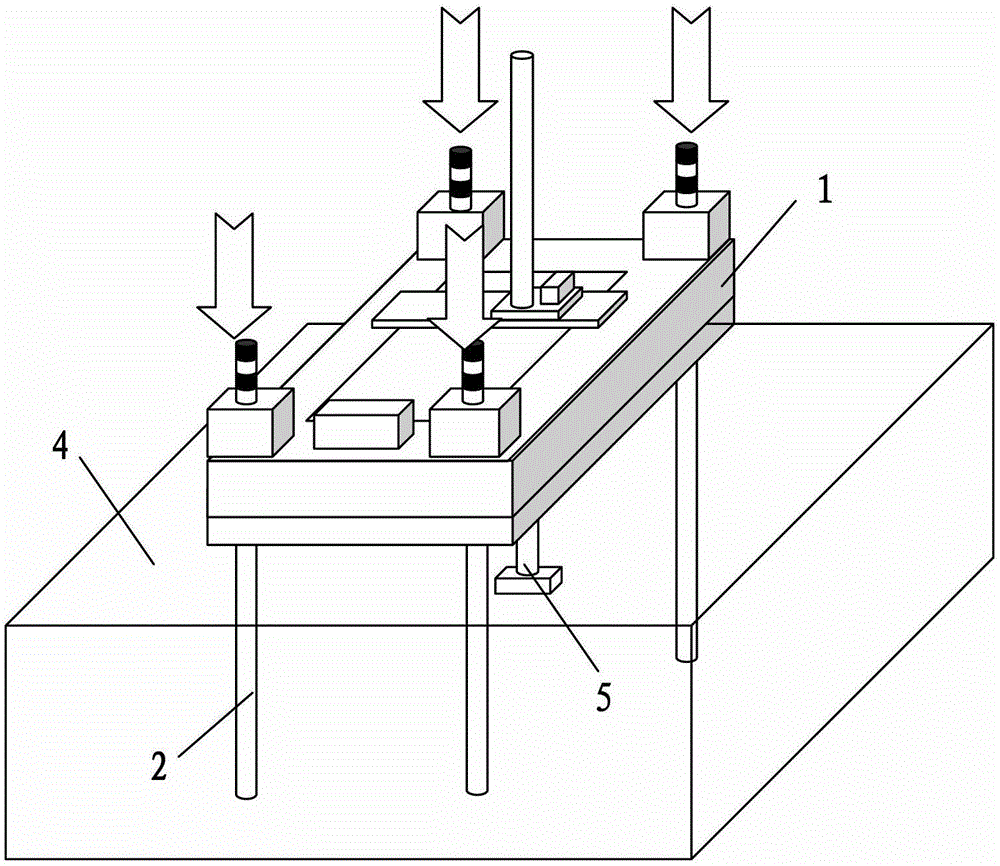

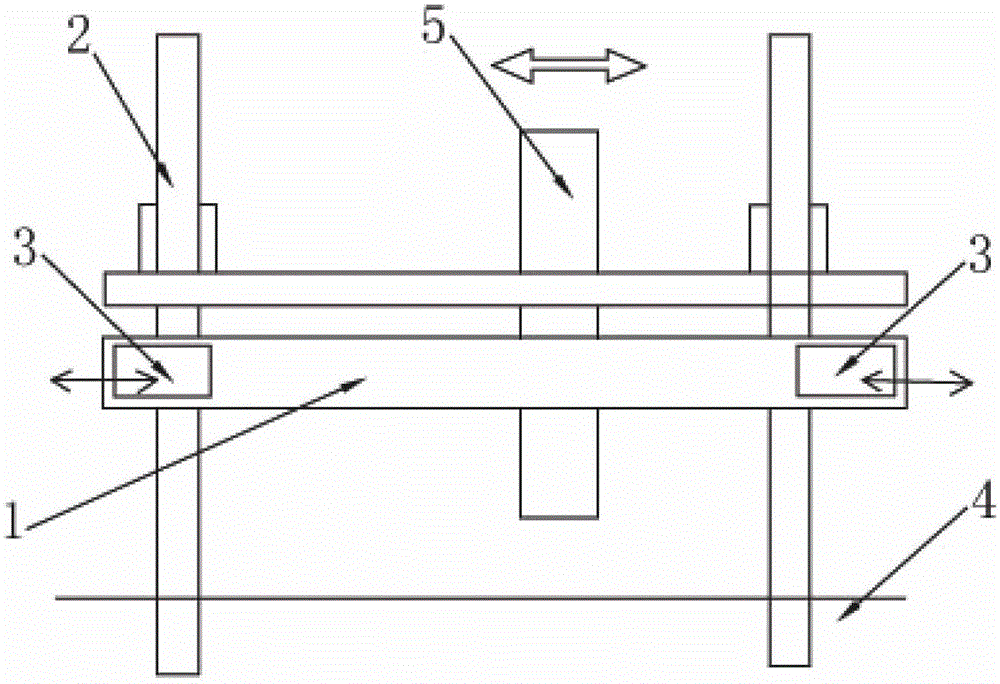

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0030] Such as figure 1 , a method for lifting equalized ballast at the four corners of a leveled ship of the present invention, comprising the following steps: S1, lowering the legs 2 on the four corners of the hull platform 1 to the mud surface, and ballasting water to the ballast tank 3 on the hull platform 1; S2. The legs 2 on the four corners of the hull platform 1 enter the mud at the same time, and continue to apply loads to the legs 2 until the legs 2 are stabilized; S3. Lift the hull platform 1 and ensure that the bottom of the ship does not leave the water surface, and then stabilize the legs 2; S4 1. Raise the hull platform 1 to the bottom of the ship to leave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com