A wind power blade girder laying system and control method thereof

A technology for wind power blades and girders, which is applied in the field of wind power blade girder laying system and its control, and can solve problems such as difficulty in application, difficulty in ensuring accuracy of manual laying, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

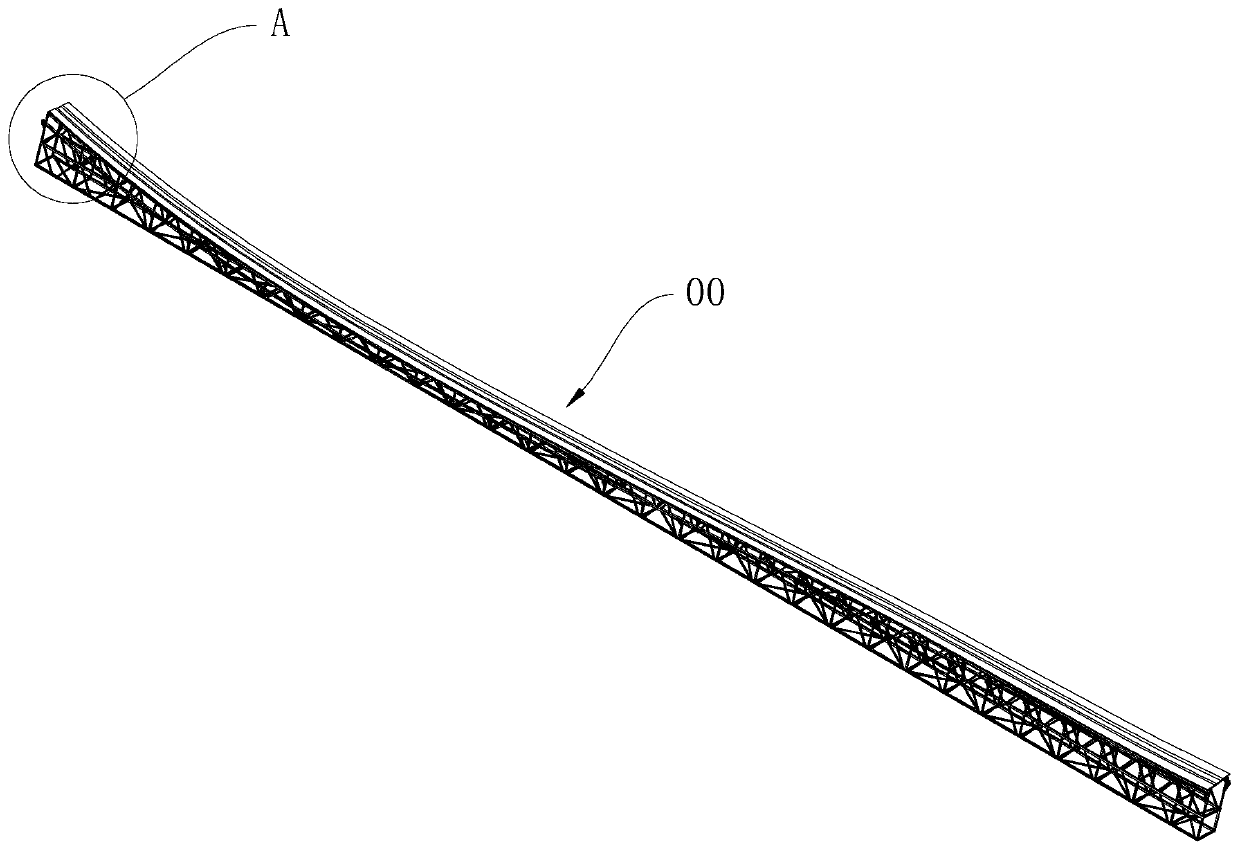

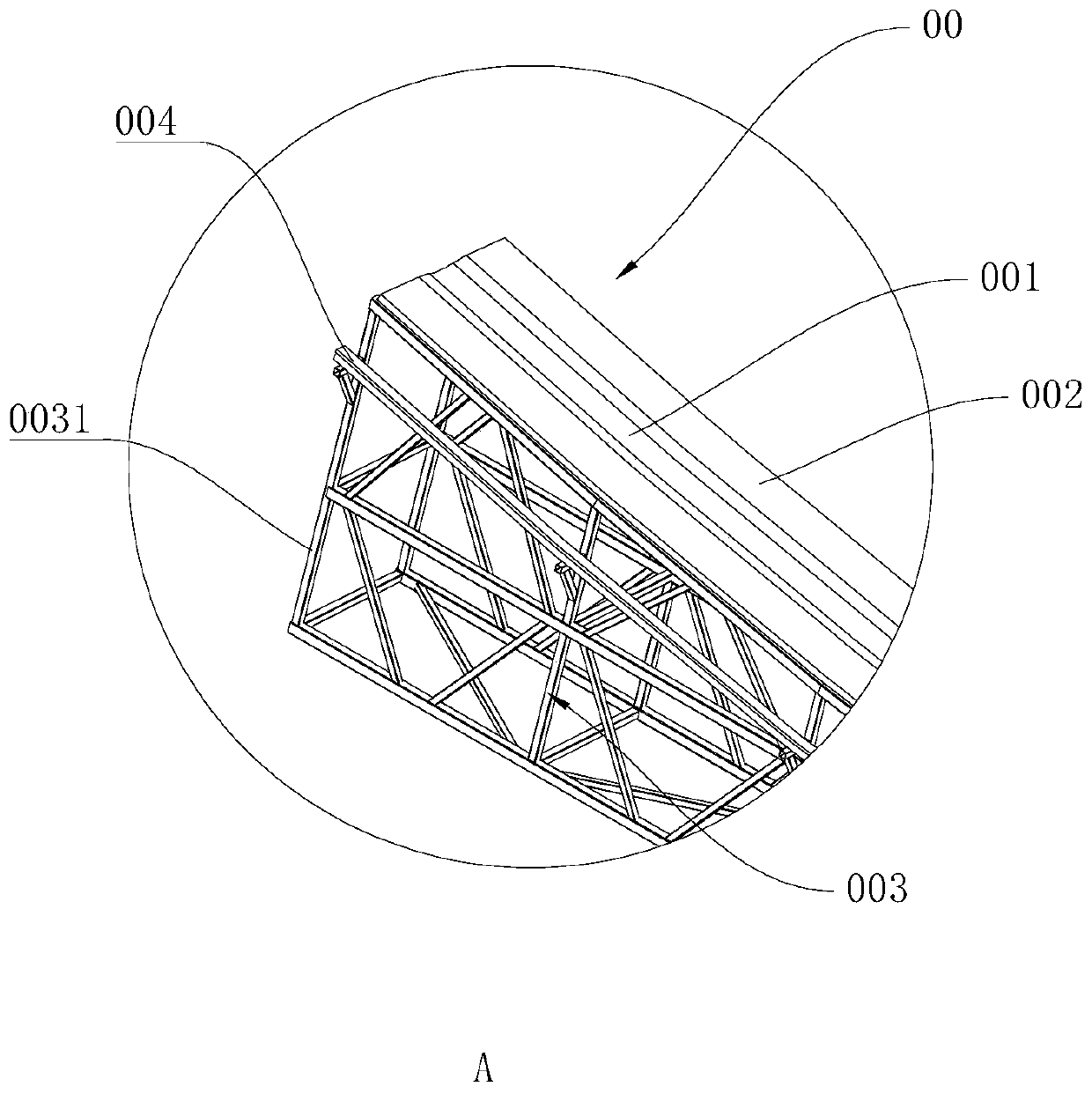

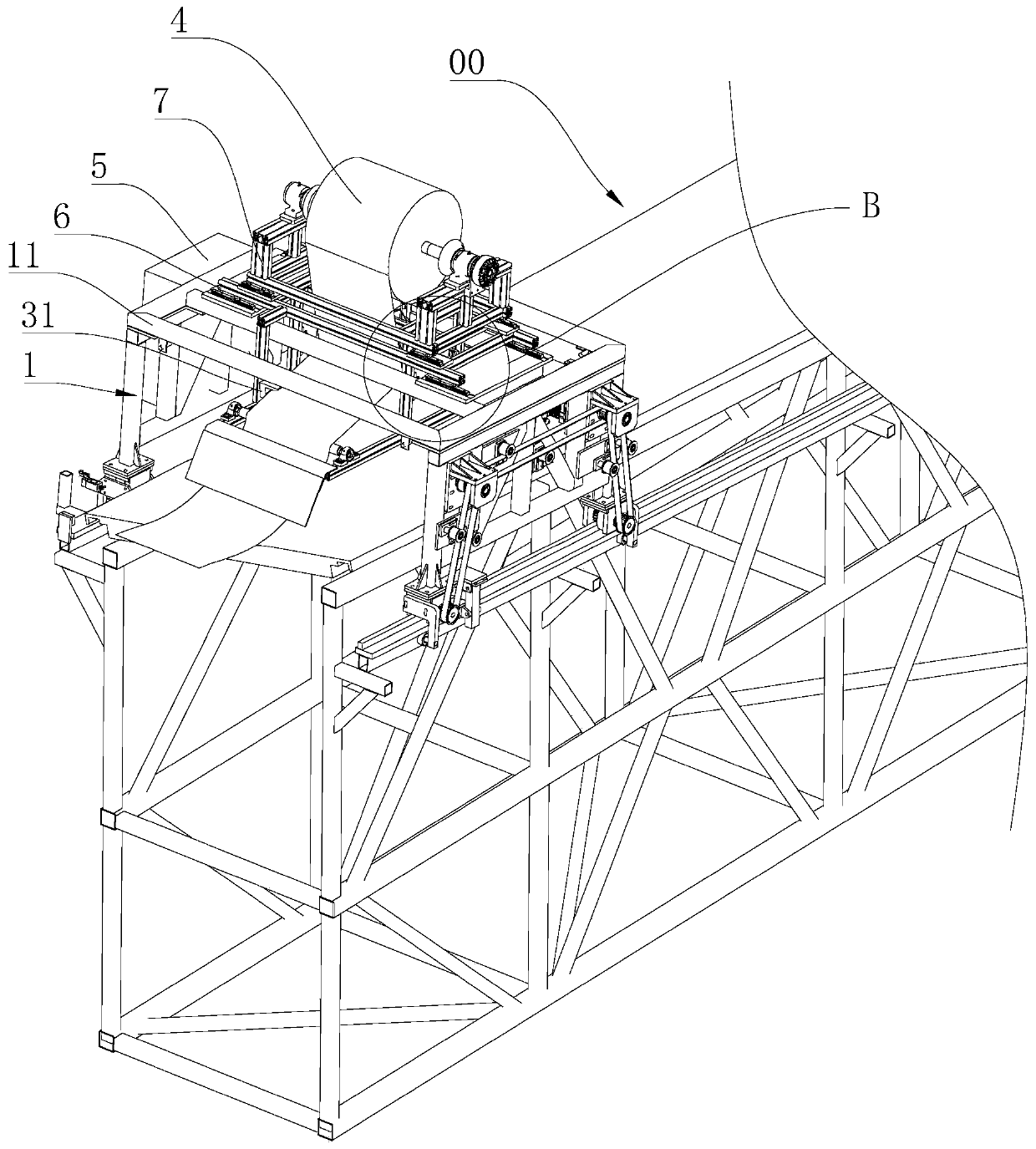

[0048] Example 1: A wind turbine blade girder laying system, such as image 3 As shown, it includes a mobile trolley 1, which moves along the track in the extension direction of the beam mold 00 for coil laying; a two-step correction device to ensure that the color yarn spacing between each layer of the coil along the extension direction of the beam mold 00 is consistent; The unwinding device 4 is used for the constant tension unwinding of the coil, which can be realized by coaxially connecting the magnetic powder brake with the air expansion shaft; the PLC controller 5 is used to control the moving trolley 1, the two-step correction device and the unwinding device 4 Actions. The mobile trolley 1 is slidably connected to a first base 6 in a direction perpendicular to the laying direction of the coils, and a second base 7 is slidably connected to the first base 6, and the unwinding device 4 is installed on the second base 7; The movement of 6 is used to adjust the distance betwe...

Embodiment 2

[0062] Embodiment 2: A control method of a wind turbine blade girder laying system, which is different from Embodiment 1 in that: Figure 3 to Figure 7 Shown, including:

[0063] S1: The mobile car 1 is erected on the rail of the beam mold 00, and one end of the coil is fixed to one end of the beam mold 00;

[0064] S2: The colored yarn sensor 21 tracks the colored yarn on the beam mold 00. After the colored yarn sensor 21 detects the colored yarn of the coil, it is transmitted to the PLC controller 5. The PLC controller 5 controls the action of the second actuator 22 to adjust the first The base 6 moves, and the moving distance is the color yarn spacing between each layer of coil;

[0065] S3: The mobile trolley 1 moves to the other end along the rail of the beam mold 00 under power to complete the laying of the first layer of coiled material. The power of the mobile trolley 1 is provided by the drive unit 13, and the coiled material is laid under constant tension. In roll form, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com