An Improved DC Tubular Motor

A tubular motor and motor shaft technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of large noise and vibration of the door body, interference with the motor control part, and reduction of the remote control acceptance distance, so as to reduce noise and vibration The output, the effect of avoiding magnetic field radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will now be described with reference to the drawings and embodiments.

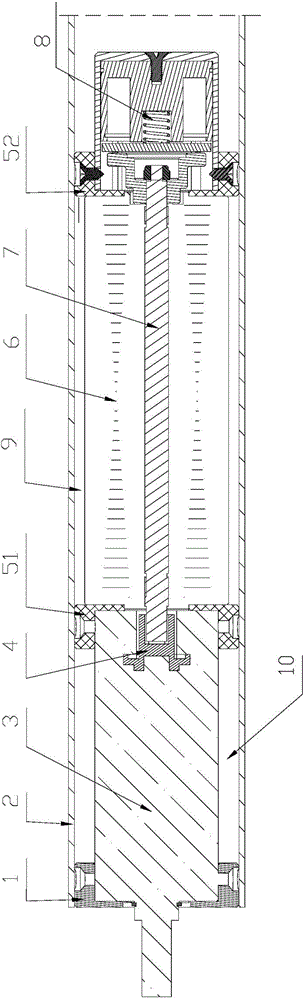

[0012] Such as figure 1 An improved DC tubular motor is shown. One end of the motor shaft 7 of the DC motor 6 arranged in the steel pipe 2 is connected to the reducer 3 through the coupling 4, and the other end of the motor shaft 7 is connected to the brake assembly 8. Two reducing sleeves 51 and 52 made of soft insulating material are respectively provided at both ends of the DC motor, which are used to fix the DC motor 6 in the steel pipe 2. The diameters of the two reducing sleeves 51, 52 are larger than the outer diameter of the DC motor 6. One of the reducing sleeves 52 is fixedly sleeved on the end of the DC motor, and the other reducing sleeve 51 is fixedly sleeved on the DC motor 6 and The connecting part of the coupling 4 provides a certain gap 9 between the DC motor 6 and the steel pipe 2.

[0013] The DC tubular motor of the present invention is also provided with a red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com