Shed-forming device for a weaving machine

A shed and loom technology, applied in the field of producing such a shed forming device, can solve problems such as changing the movement route, and achieve the effect of easy setting or adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

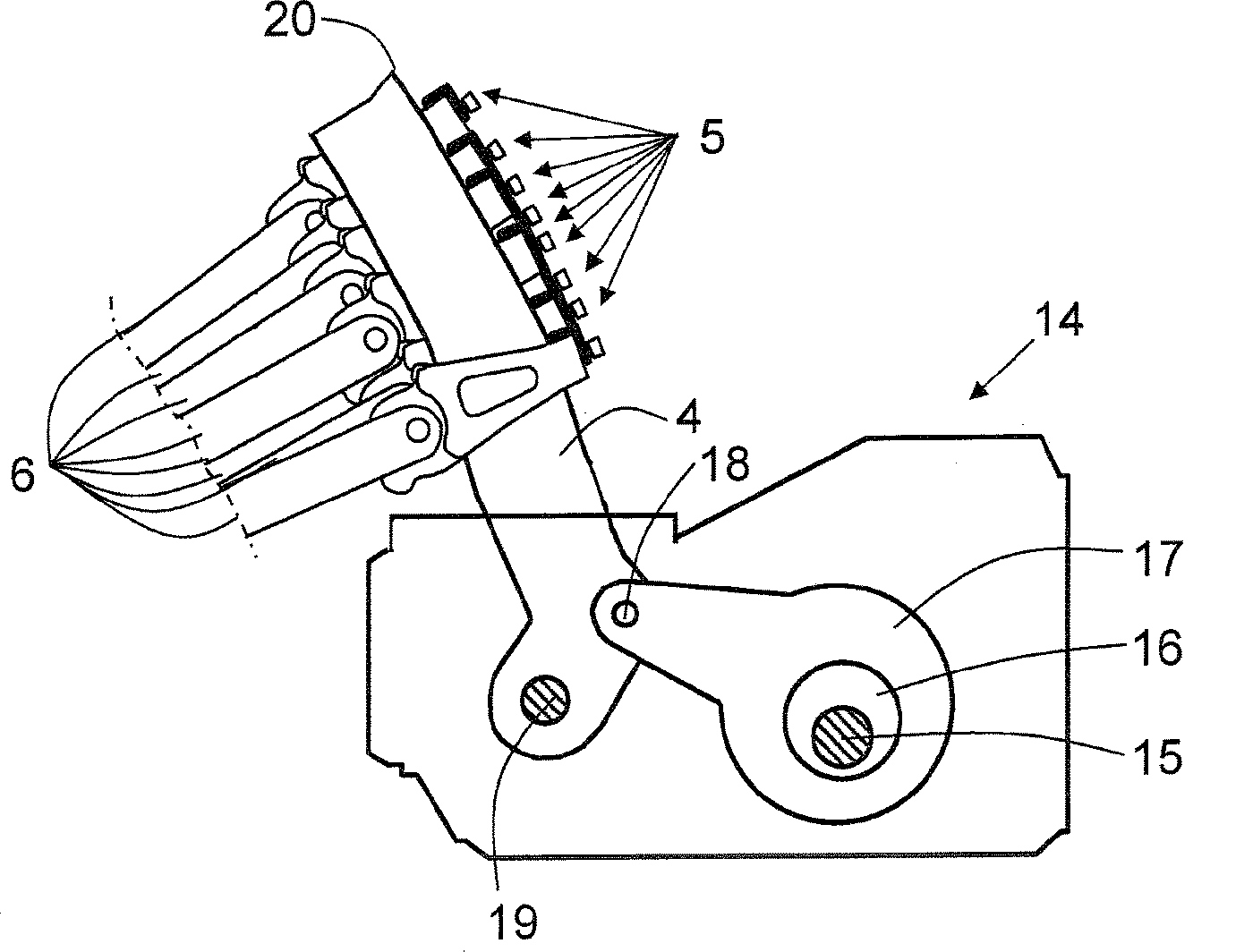

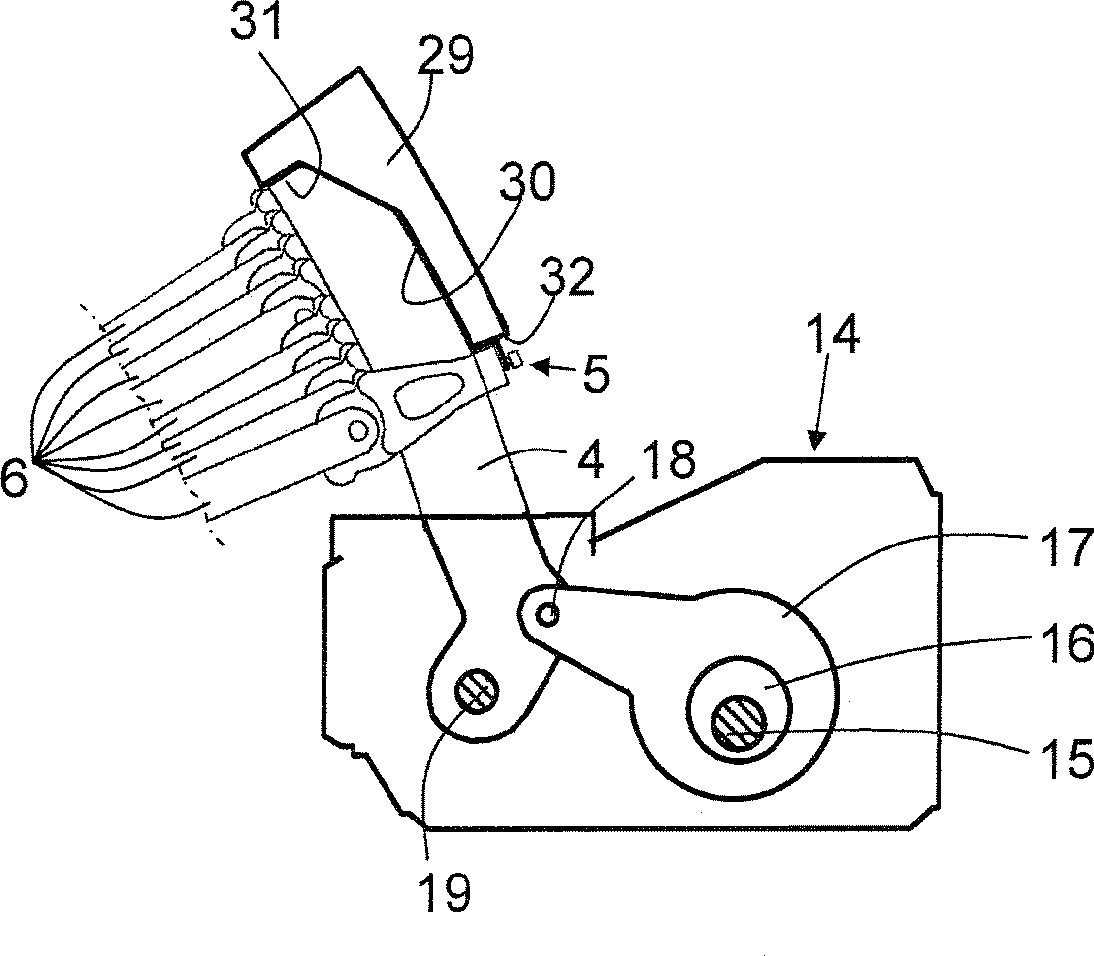

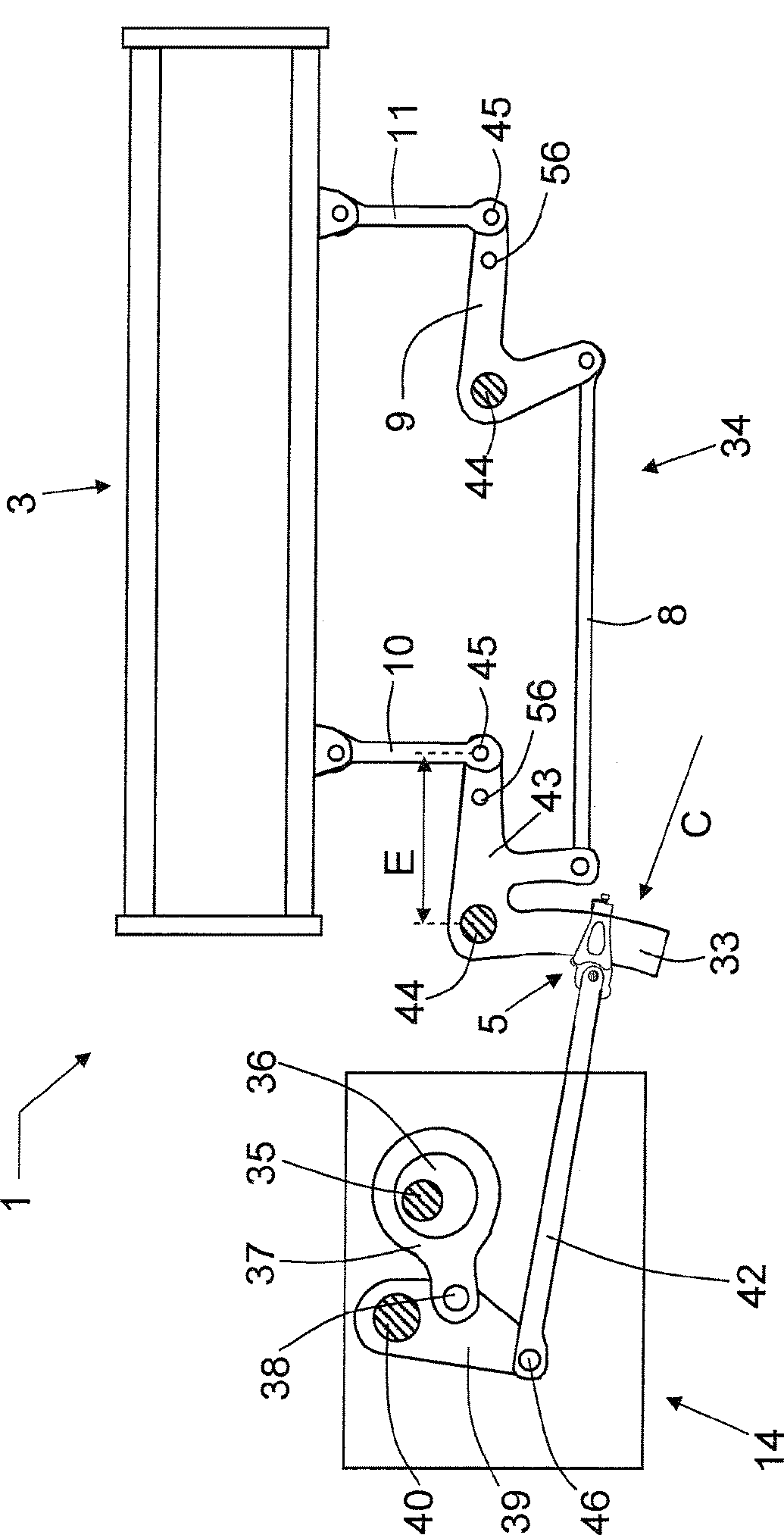

[0047] FIG. 1 schematically shows a perspective view of an embodiment of a shedding device 1 with a plurality of transmissions 2 each connected to a heald frame 3 . In general, weaving is carried out with at least two different heald frames 3 , each driven via an associated transmission 2 . For clarity of illustration, only two heald frames 3 are shown. The shedding device 1 also comprises a different drive rod 4 connected to the bar 6 of the transmission mechanism 2 via a settable connection 5 . The transmission mechanism 2 also includes a first hinge rod 7 , a horizontal rod 8 , a second hinge rod 9 and vertical rods 10 and 11 . The transmission mechanism is used to convert the reciprocating motion of the coupled driving rod 4 into the up and down motion of the heald frame 3 . In this case, the heald frame 3 can move in guides 12 and 13 of the loom (not shown). Furthermore, a drive device 14 for driving the drive rod 4 is shown. With a plurality of heald frames 3 a shed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com