Gas pump with reduced noise generation

A technology of air pumps, pump housings, applied in the direction of pumps, pump elements, parts of pumping devices for elastic fluids, capable of solving problems such as discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

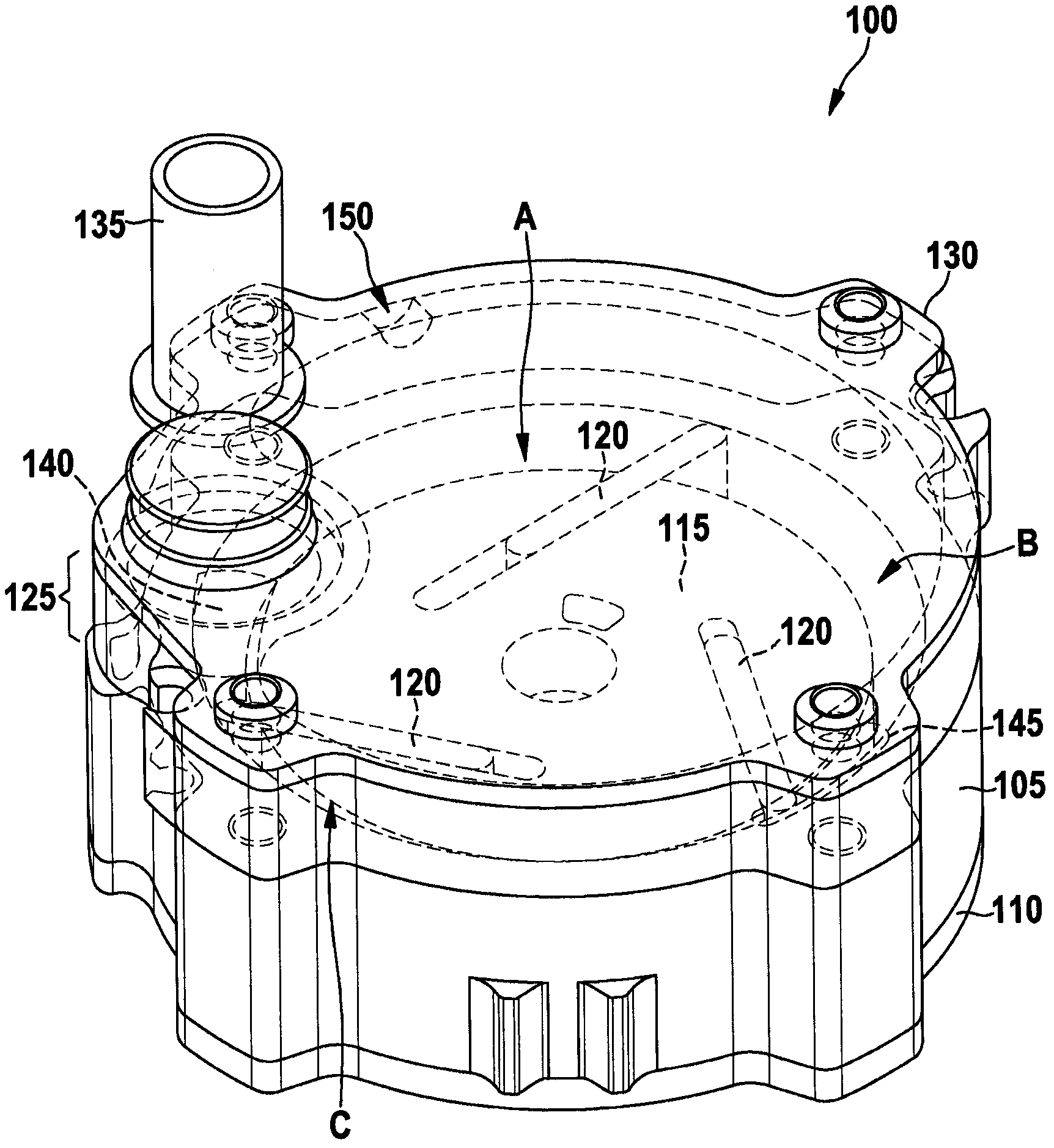

[0017] figure 1 A perspective view of the air pump 100 is shown. The air pump 100 comprises a pump housing 105 which is closed downwards by a pump base 110 . A pump rotor 115 is arranged in the pump housing, which is rotatable about a vertical axis. For this purpose, the pump rotor 115 is driven by means of a shaft (not shown) by an electric motor arranged below the pump floor 110 .

[0018] The pump rotor includes three slots extending at an angle from a circumference around the axis of rotation of the pump rotor to the outer edge of the pump rotor 115 . A sliding element 120 is accommodated in each of the grooves, which is held in the inner circumference of the pump housing 105 by centrifugal force and / or spring elements. The inside of the pump housing 105 is a cylindrical shell surface around a central axis that is offset parallel to the axis of rotation of the pump rotor 115 . The pump units (Pumpenzelle) A to C therefore have different volumes, which are related to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com