Automatic feeding device for press mounting of steel balls

An automatic feeding and press-fitting technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of time-consuming, high labor intensity of operators, and affecting the efficiency of press-fitting operations, so as to improve work efficiency and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

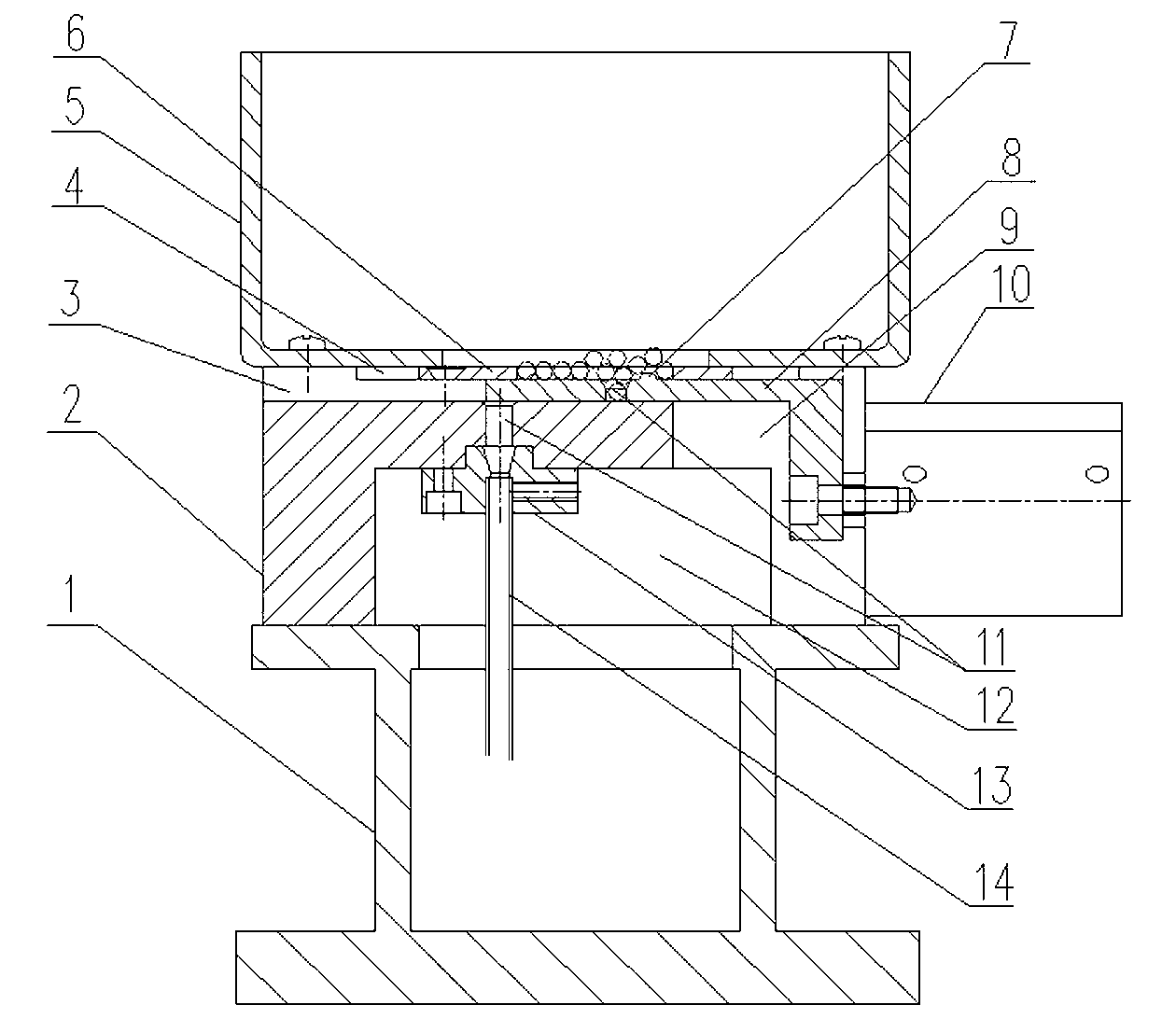

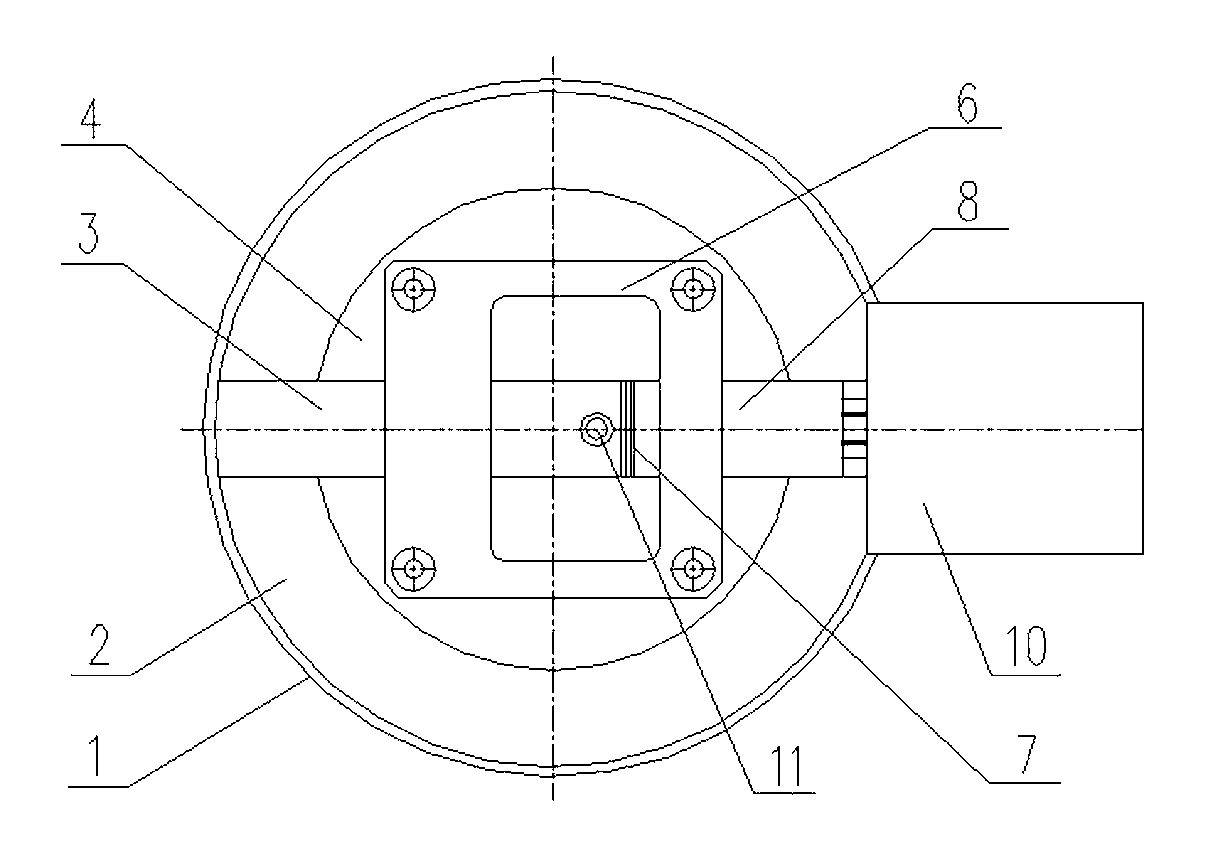

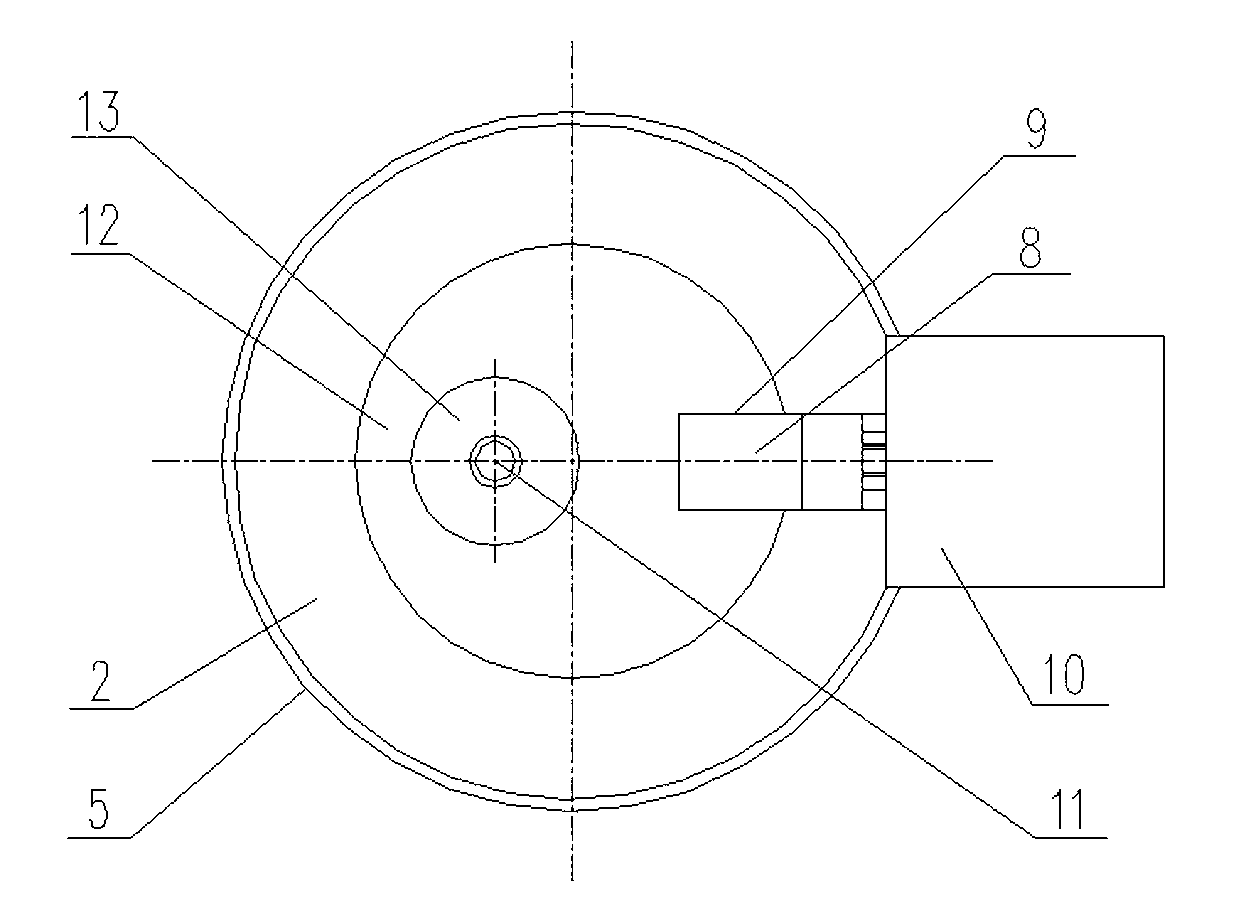

[0012] The automatic feeding device for steel ball press-fitting of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] Such as Figure 1 to Figure 3 As shown, the automatic feeding device for steel ball press-fitting of the present invention includes a bracket 1, which is composed of a vertically arranged cylinder and two cover plates located at both ends of the cylinder and integrated with the cylinder. The cover plate at the upper end has a central hole. There is a feeding block 2 on the support 1, the feeding block 2 is short cylindrical, and its upper surface has a round flat bottom pit 4 and a long groove 3 that runs through both ends, the round flat bottom pit 4 is concentric with the feeding block 2, and the long groove 3 The longitudinal centerline of the center of the round flat bottomed pit 4 passes through, and the depth of the long groove 3 is greater than the depth of the round flat bottomed pit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com