Main tight wire replacing method of elevator

A replacement method, the technology of the main steel cable, which is applied to the hoisting equipment, elevators, transportation and packaging in the mine, can solve the problems of increasing self-weight and increasing the burden on the operator, so as to reduce the components, reduce the burden, and ensure operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

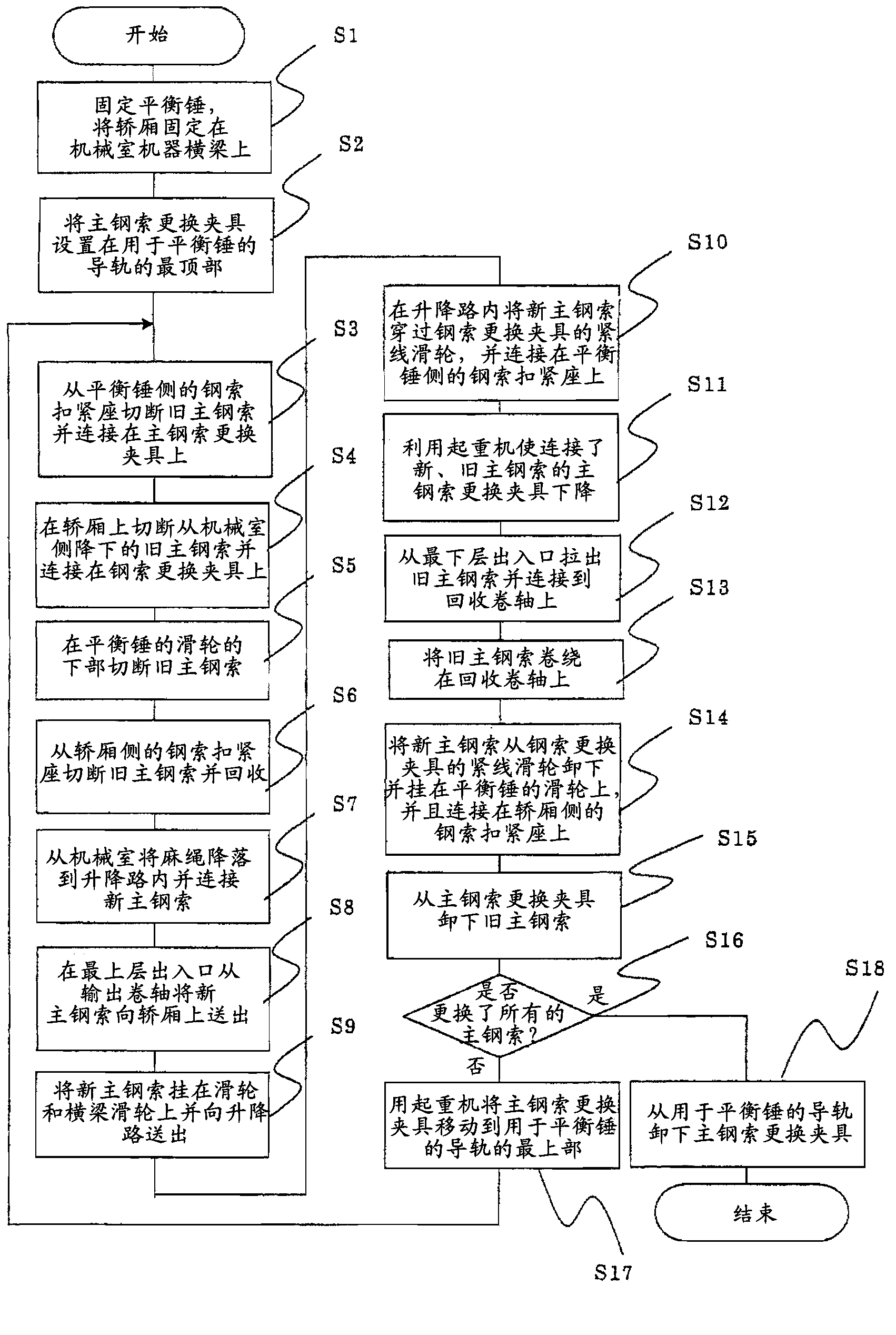

Method used

Image

Examples

Embodiment Construction

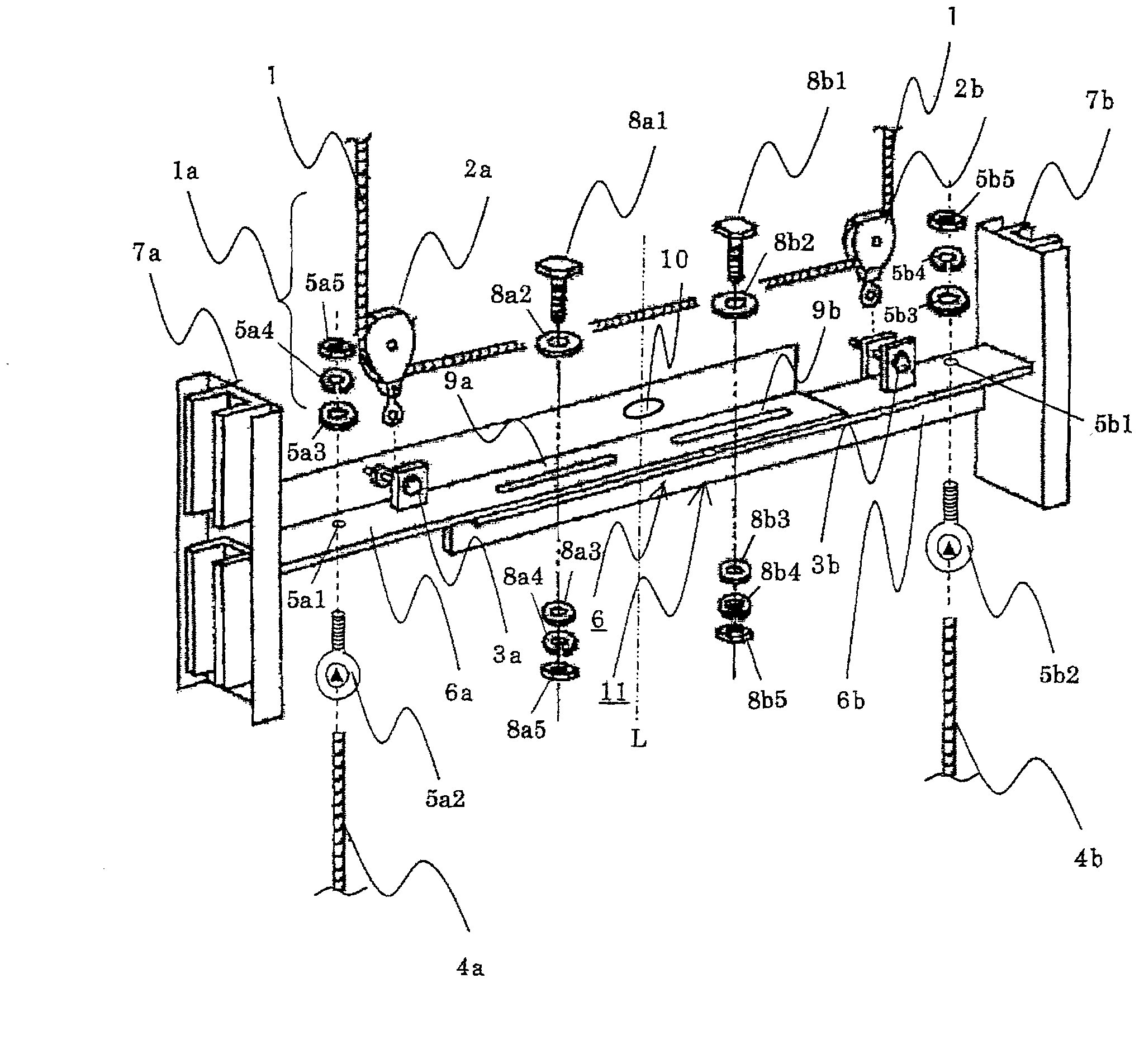

[0034] Hereinafter, the form for carrying out the main rope replacement method of the elevator of this invention is demonstrated based on drawing. In addition, the same code|symbol is attached|subjected to the part which overlaps with the description of the said prior art.

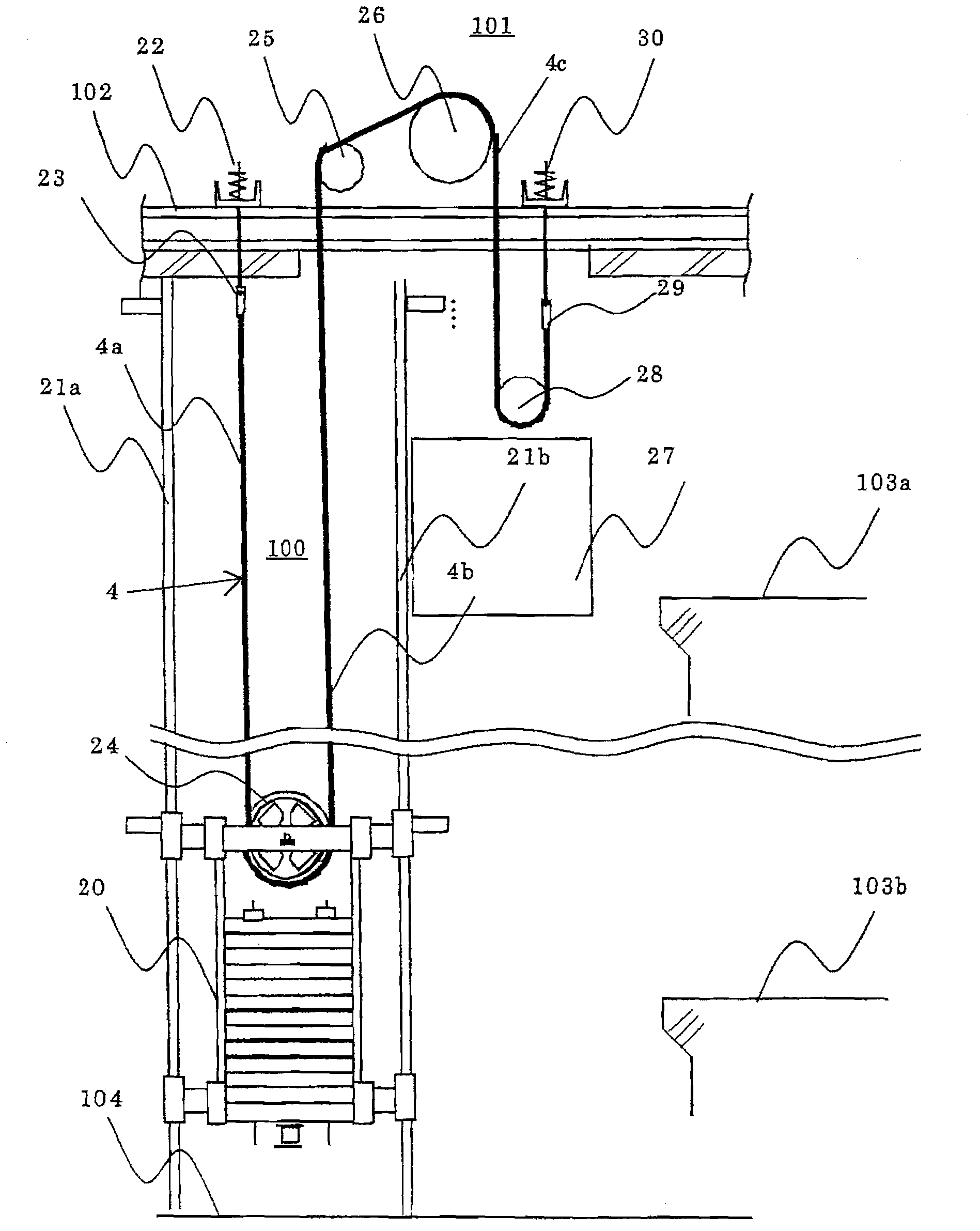

[0035] An elevator applying an embodiment of the main steel rope replacement method of the elevator of the present invention includes: for example image 3 Shown are a car 27 installed on the hoistway 100 and stopped on each floor; a counterweight 20 suspended via the car 27 and main ropes 4 ; and a pair of guide rails 21a, 21b guiding the counterweight 20 . Furthermore, in this embodiment, the elevator is constituted by a 2:1 roping ratio elevator, and as will be described later, the main rope replacement work of this embodiment is mainly performed on the uppermost floor 103a among the floors. and the lowermost laminate 103b. In addition, a plurality of main steel cables 4 are erected.

[0036] The hoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com