Constant force cupping

A constant force, tank technology, applied in the direction of suction equipment, etc., can solve the problems of easy failure, complicated cupping operation, etc., and achieve the effect of no safety hazard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

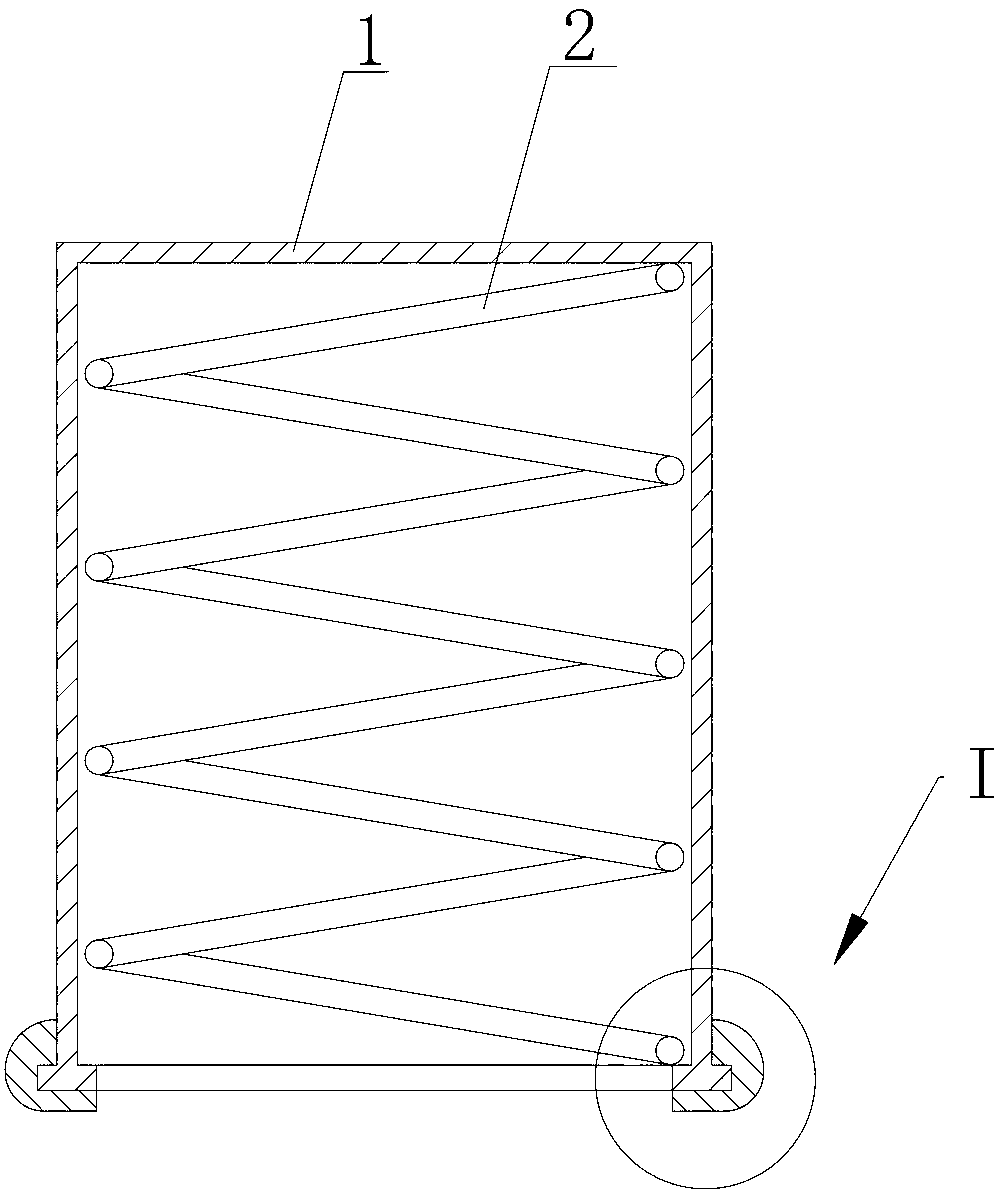

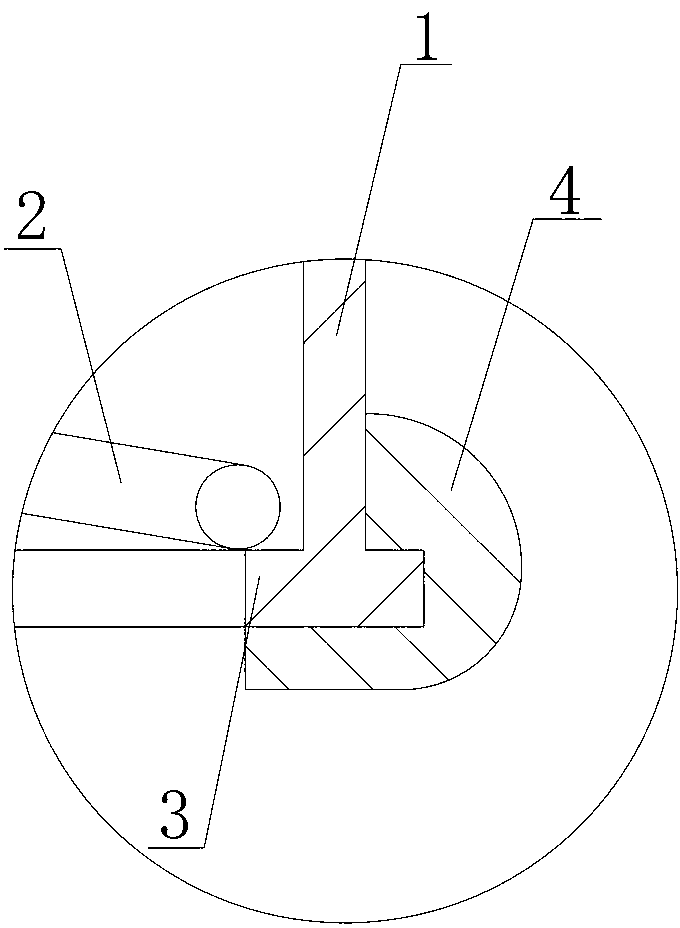

[0026] Such as figure 1 and figure 2 Commonly shown is an embodiment of the constant force cupping of the present invention, which includes an elastic tank body 1, the tank body 1 can be made of rubber or latex material, and its shape can be cylindrical or square shape etc.

[0027] The inside of the tank body 1 is provided with an elastic body for restoring the tank body 1 to its original state. The elastic body here is a compression spring 2, and the compression spring 2 realizes its function through the following structure:

[0028] The inner wall of the tank body 1 is provided with a position-limiting boss 3, and the clip spring 2 is vertically arranged, and its upper end leans against the top of the tank body 1, and its lower end leans against the position-limiting boss 3, so that when the tank body 1 is When compressed, the compression spring 2 is compressed at the same time, and the compression spring 2 produces an elastic force on the tank body 1 to restore it to it...

Embodiment 2

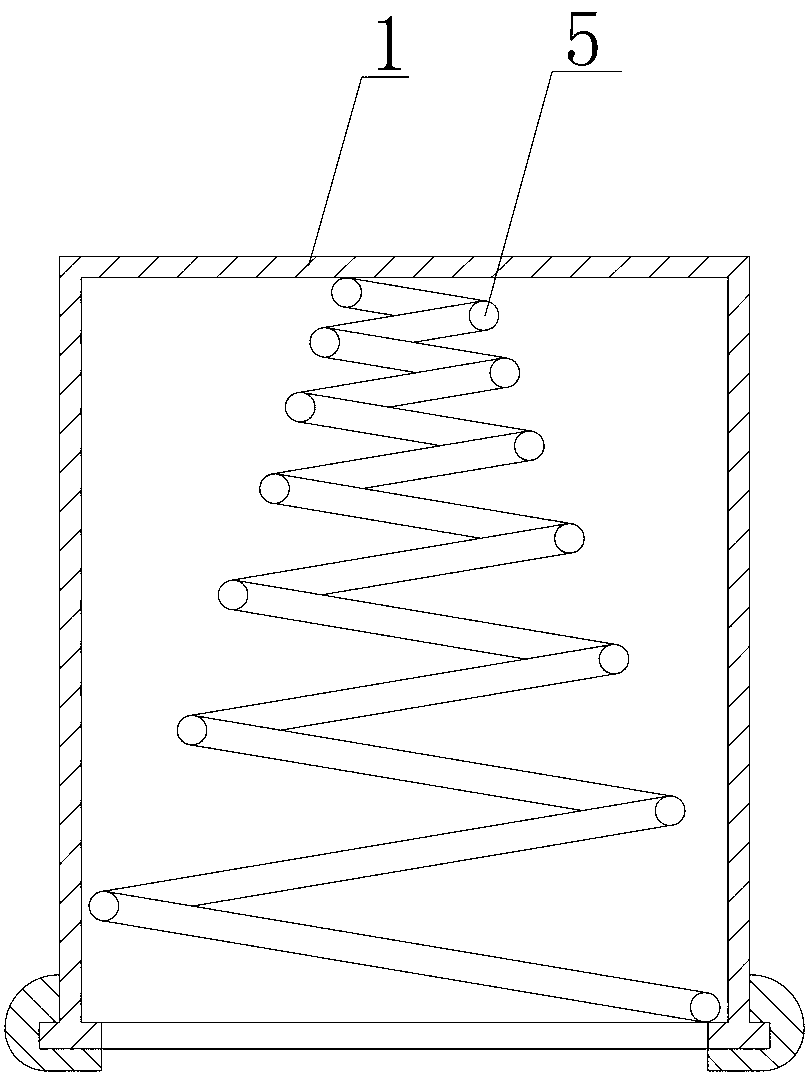

[0033] Such as image 3 Shown, is another embodiment of the constant force cupping of the present invention, and it and figure 1 The difference is that the elastic body in this embodiment uses a conical compression spring 5, the tip of which leans against the top of the tank body 1, and the larger end leans against the limit boss 3, which can also make the tank Body 1 restores its original shape. The rest of the structure in this example is the same as figure 1 are the same and will not be repeated here.

[0034] The method of using the constant force cupping is:

[0035] The operator compresses the tank body 1 and the compression spring 2 to a certain extent, and then buckles the tank body 1 at the place where cupping is required. After releasing the hand, the tank body 1 tends to return to its original shape under the elastic force of the compression spring 2 , at this time, a negative pressure is generated in the tank body 1, so that the tank body 1 is adsorbed on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com