Numerical control lathe with grinding function

A CNC lathe, functional technology, applied in the field of CNC lathe, can solve the problems of lack of precision and surface roughness, low production efficiency, large grinding allowance, etc., achieve less auxiliary time, high production efficiency, and no positioning error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

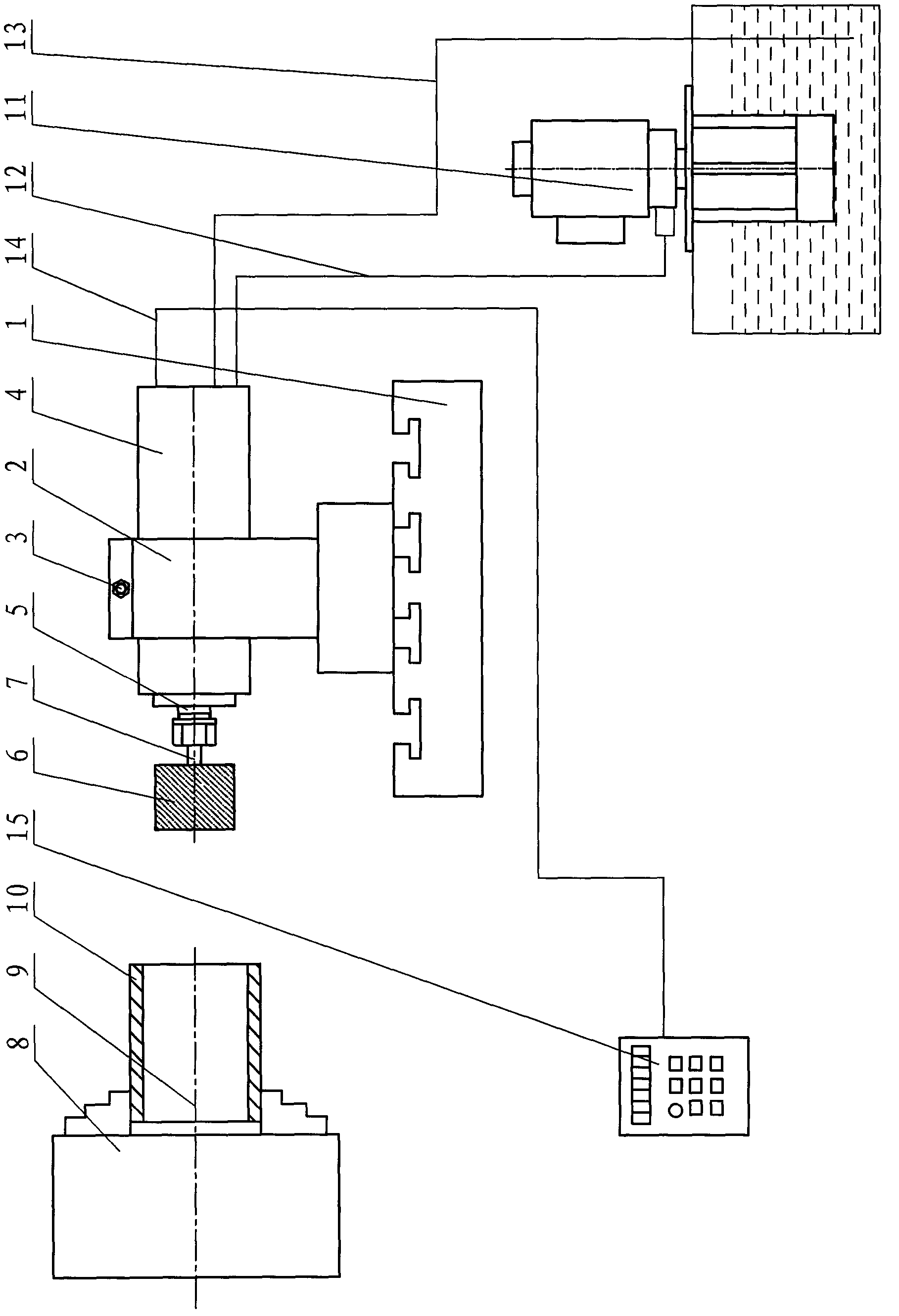

[0011] figure 1 It is a schematic diagram of the structure of the grinding device installed on the carriage in the CNC lathe. It includes a CNC lathe (not shown in the figure), on the middle carriage 1 in front of the CNC lathe rotating tool rest (not shown in the figure), a seat frame 2 is fixed, and the seat frame 2 is formed with an opening groove, The motor 4 is clamped and fixed by the bolt 3, and the grinding head 6 is installed on the shaft head 5 of the motor 4. The rotary shaft 7 of the grinding head 6 is parallel to the rotary shaft 9 of the CNC lathe chuck 8, and the center heights of the two rotary shafts are the same. . The rotation direction of the grinding head 6 is opposite to the rotation direction of the workpiece 10 to be ground. Described motor 4 adopts the main shaft motor of high-speed precision internal and external gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com