Circular tube form tracking laser cutting machine

A laser cutting machine, tracking technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of product scrapping, cutting position offset, confusion, etc., to improve processing accuracy and production efficiency, reduce The effect of scrap rate and accurate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

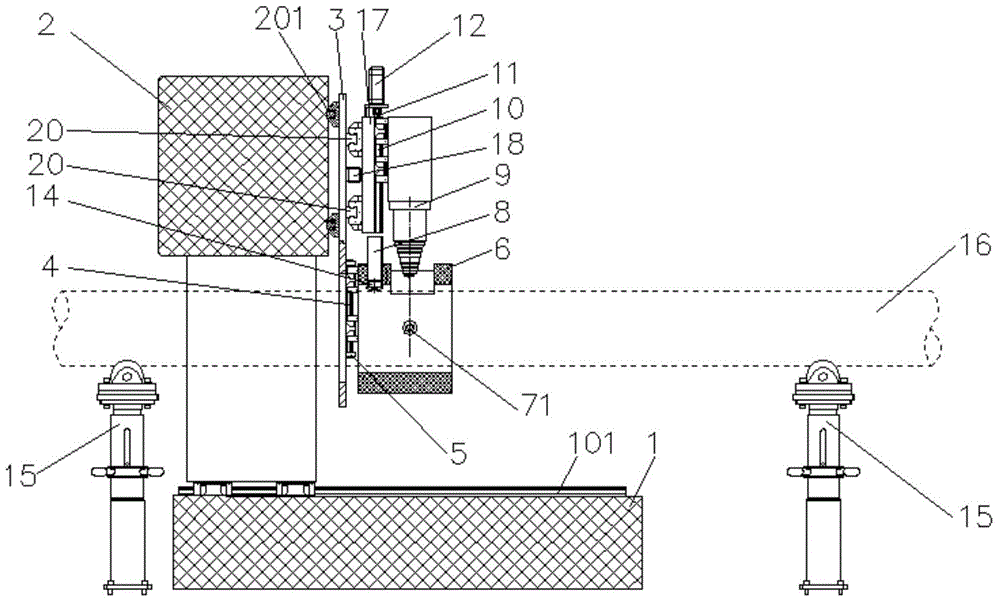

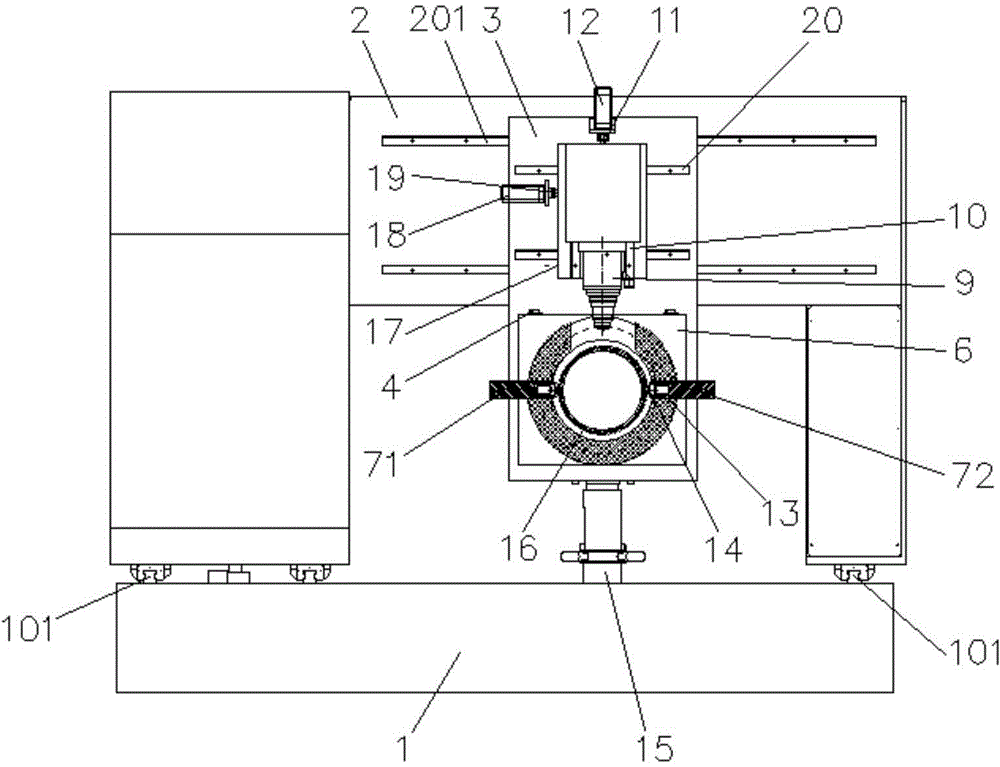

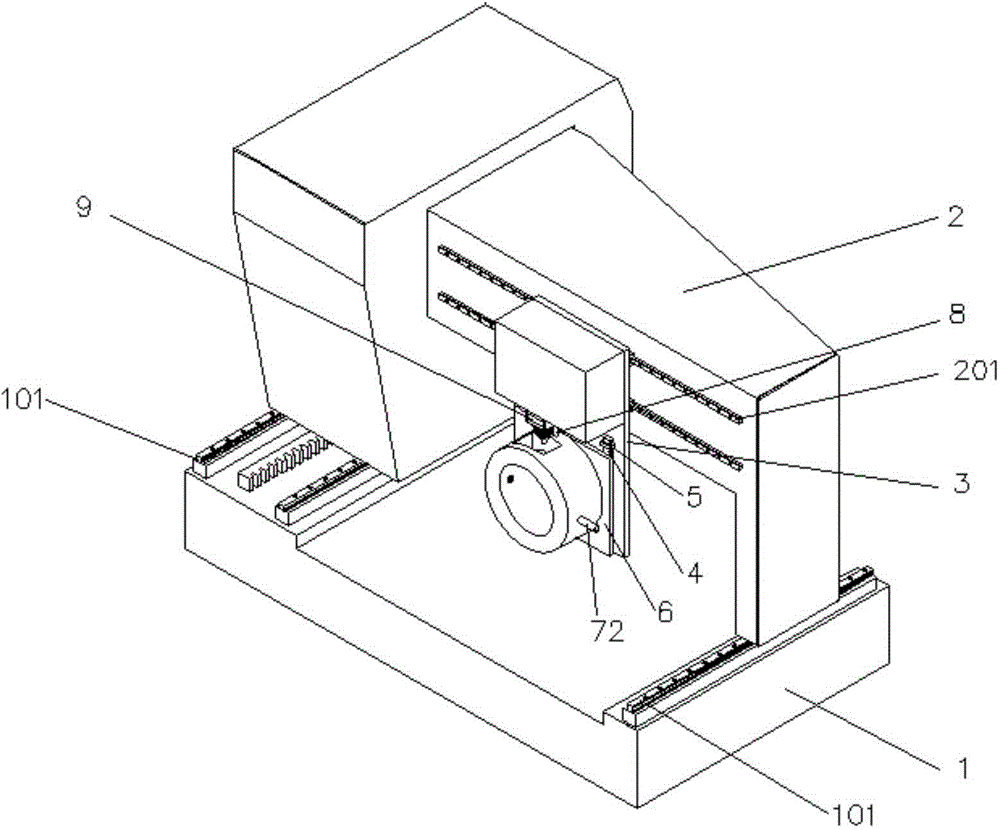

[0017] Embodiment: a circular tube shape tracking laser cutting machine, including at least two tube supports 15, a base 1, a beam 2, a first pallet 3, a second pallet 17, a cutting head 9, a support plate 6, a control device and the first, second, and third driving devices, and the three directions perpendicular to each other are respectively the X direction, the Y direction and the Z direction, and the Z direction is the vertical direction, and the two pipe fittings for supporting the pipe fitting 16 to be processed The support body 15 is fixedly positioned on both sides of the base 1 along the X direction. The base 1 is provided with a beam 2 that can slide back and forth linearly along the X direction. The first driving device is fixed on the base 1, and the first driving device drives the beam 2 along the X direction. direction movement, the first pallet 3 can be freely linearly reciprocated and positioned on the beam 2 along the Y direction, the second pallet 17 can be li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com