Container for containing liquid

A liquid and container technology, applied in the direction of buoy liquid level indicator, etc., can solve problems such as false alarms, and achieve the effect of avoiding false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

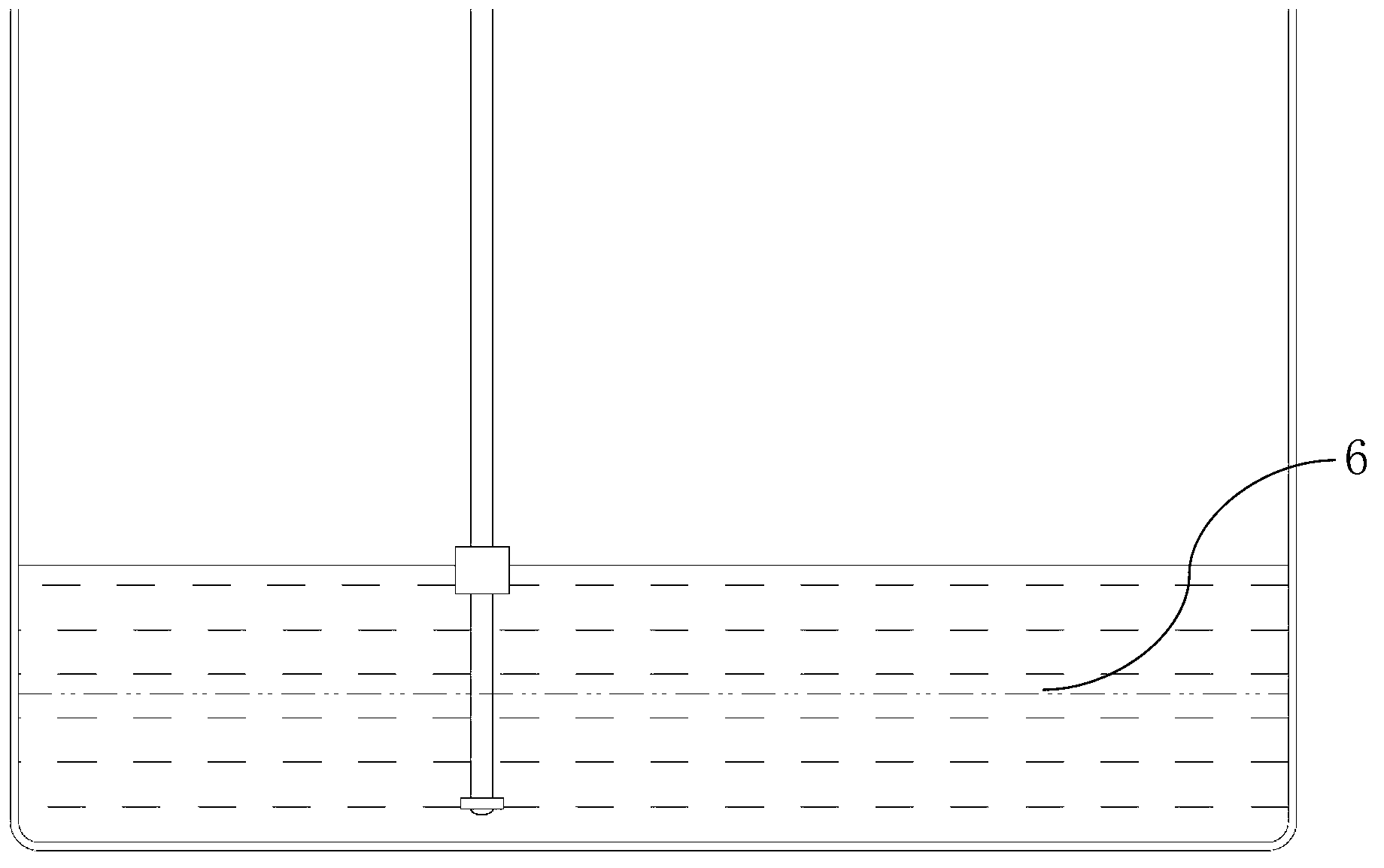

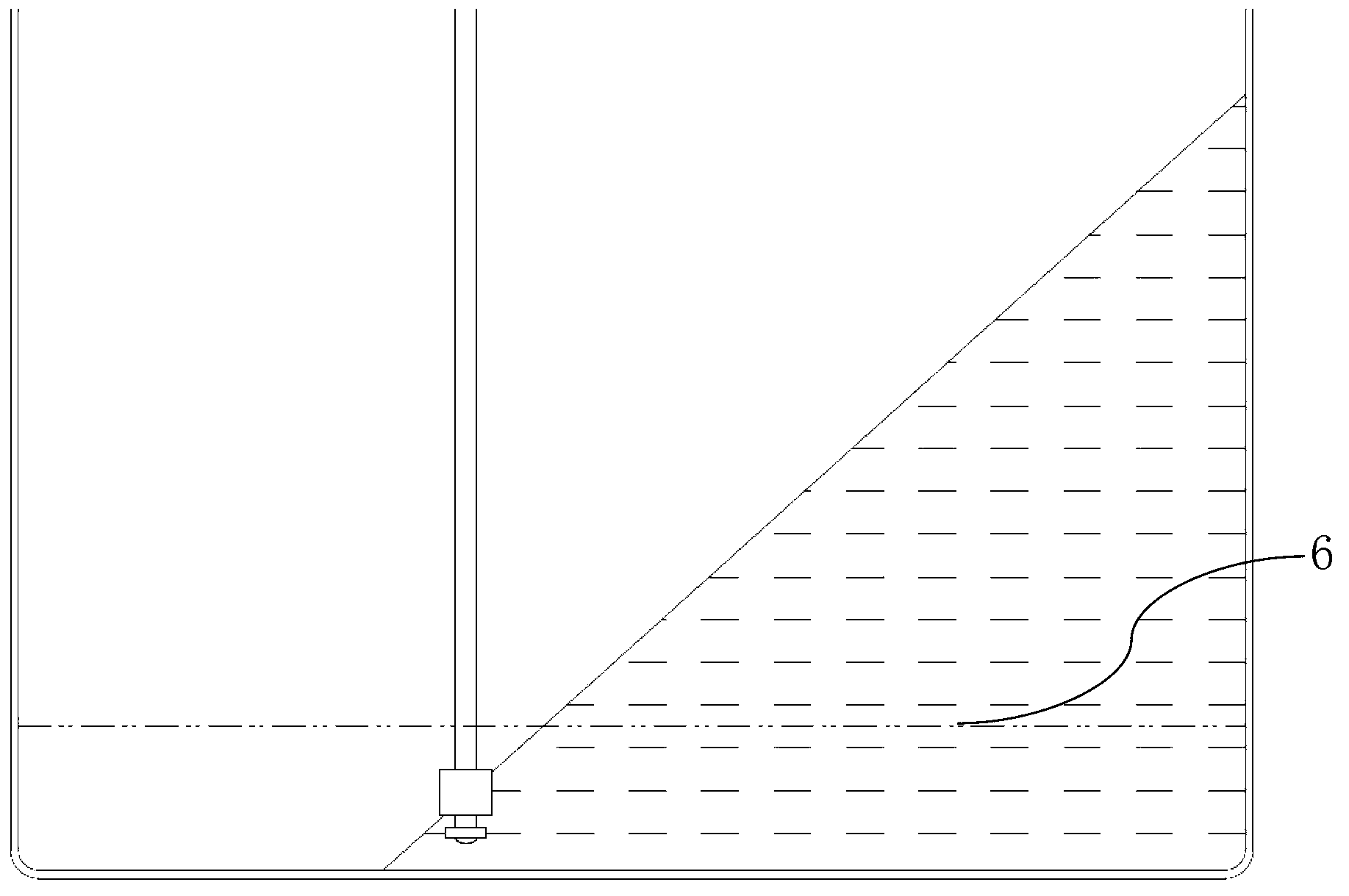

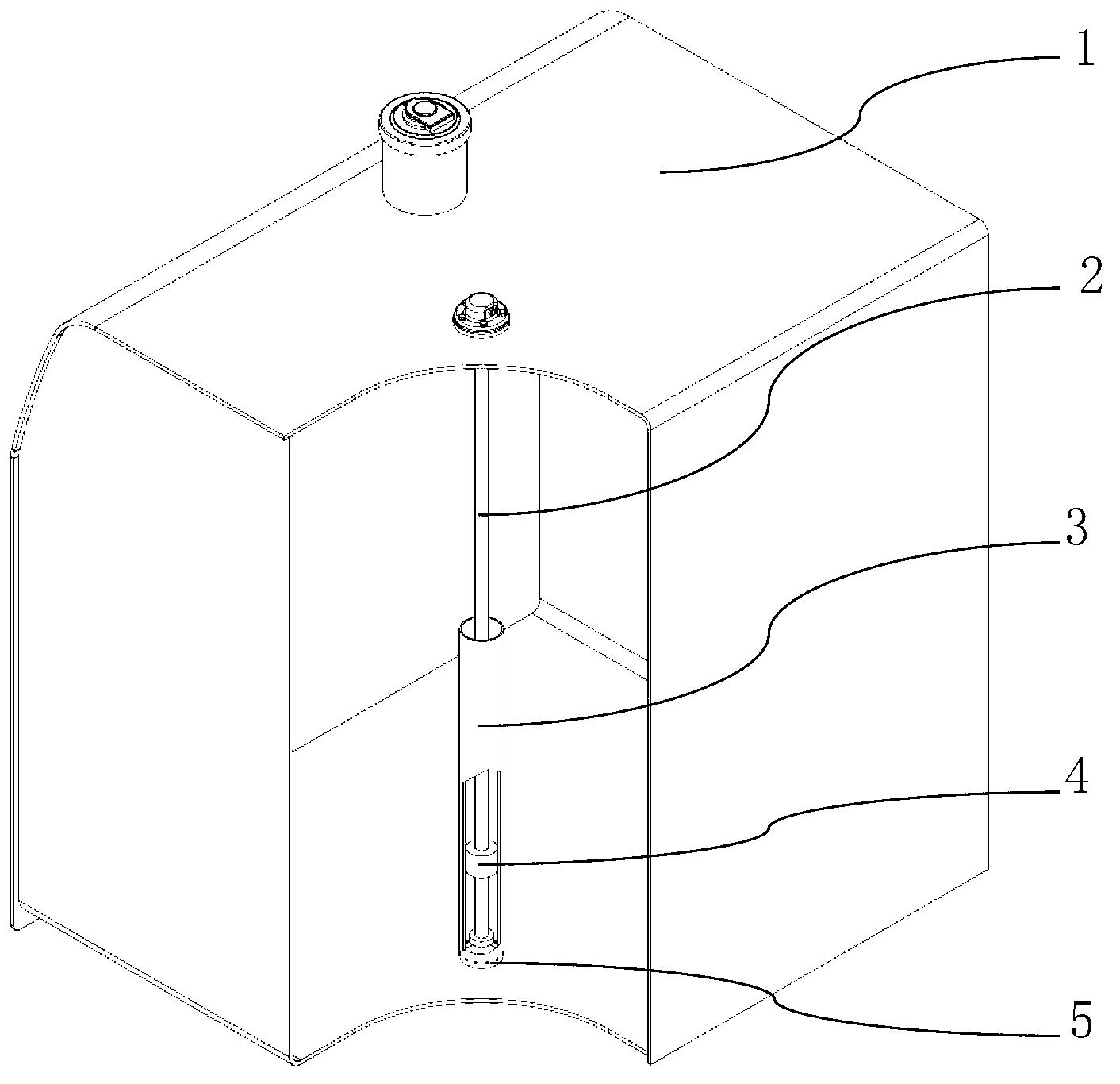

[0025] like Figure 3 to Figure 6 As shown, in this embodiment, the container containing the liquid includes a container body 1, and a liquid level sensor is arranged in the container body. The liquid level sensor includes an induction body 2 and an induction float 4. The induction body 2 is columnar and vertical Set in the container body 1, the induction float 4 is set on the induction body 2, and its equivalent density is lower than the density of the liquid contained in the container body, so that the induction float 4 can float on the liquid surface and move up and down with the induction body 2 float. The magnetic properties of the sensing float 4 conduct the internal resistance of the sensing body to achieve different resistance values at different liquid levels, which are converted into liquid level signals through a certain algorithm, and the height of the liquid level is obtained to further obtain the liquid capacity in the container body. In the container body, a ...

Embodiment 2

[0027] like Figure 7As shown, in this embodiment, the liquid level sensor includes a cylinder, a sensing float, and a cylinder, and a sensing device is arranged inside the cylinder, and the sensing float is sleeved on the cylinder, and floats up and down with the height of the liquid level. And interact with the liquid level sensing device 8 in the column to generate a liquid level signal, and the top of the column is fixedly connected with the top cover 7 as the head of the liquid level sensor. The upper end of the cylinder 3 is also fixedly connected with the top cover 7 by bolts, the cylinder 9 is located in the cylinder 3, the upper part of the cylinder 3 communicates with the outside of the cylinder, and the lower part of the cylinder 3 communicates with the outside of the cylinder with a damping hole 5 . In this embodiment, the liquid level sensor is vertically installed in the container containing the liquid. When the container does not vibrate violently, that is, the...

Embodiment 3

[0029] like Figure 8 As shown, compared with Embodiment 2, the difference is that the liquid level sensor in this embodiment does not have a cylinder in the inner cavity of the cylinder 3, and the sensing device 8 is directly arranged in the cylinder wall of the cylinder 3, and the cylinder 3. It is fixedly connected with the head of the liquid level sensor, that is, the top cover 7. In this embodiment, the upper part of the cylinder body can also be an integrated structure with the head of the liquid level sensor, and a detachable bottom cover is provided at the bottom of the cylinder body to facilitate the loading and unloading of the sensing float.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com