Equipment and method for changing cylinders and/or clusters of a roll stand

A technology of rolling mill stand and roll group, applied in the direction of metal rolling stand, metal rolling mill stand, roll, etc., can solve the problem of no device, no existence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

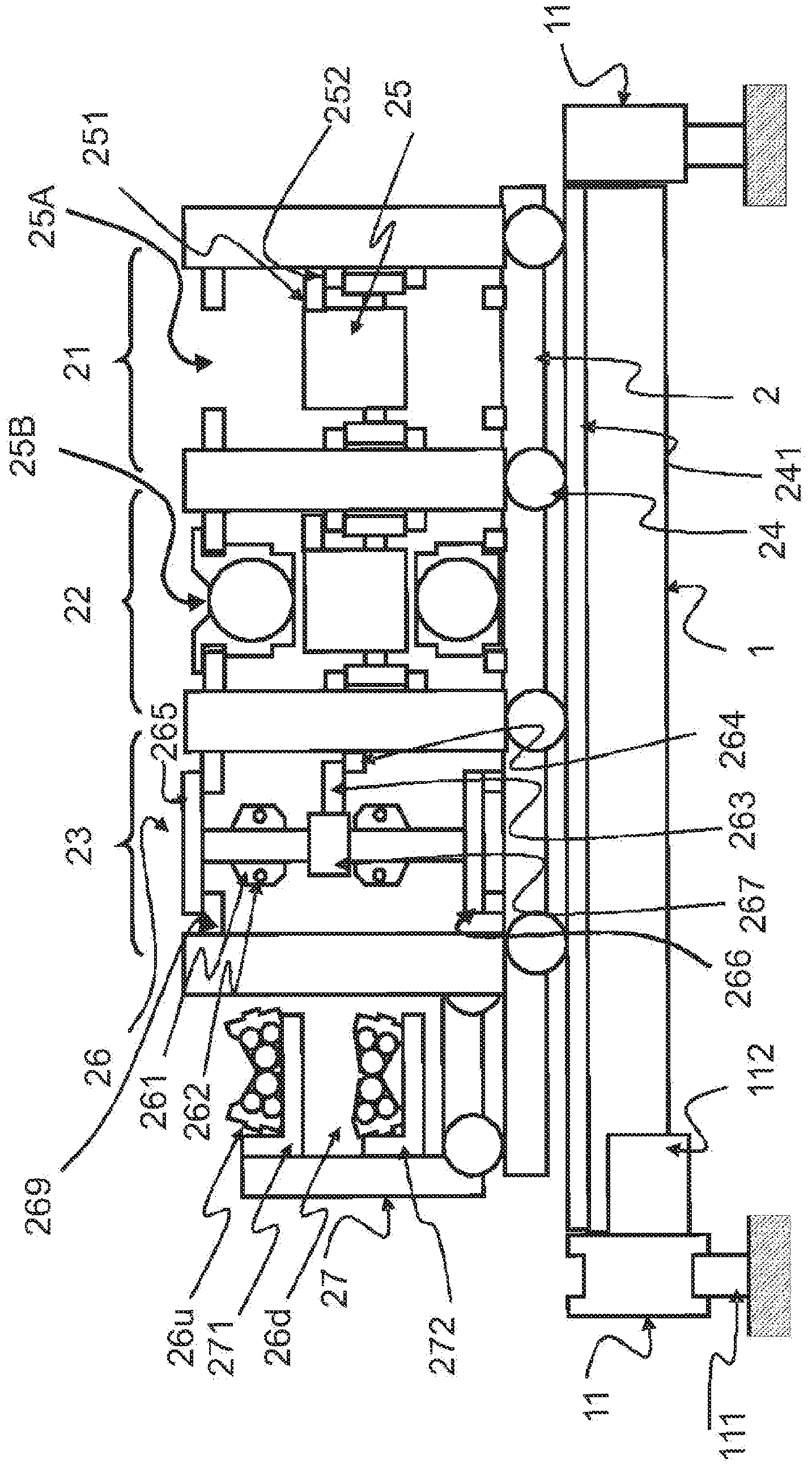

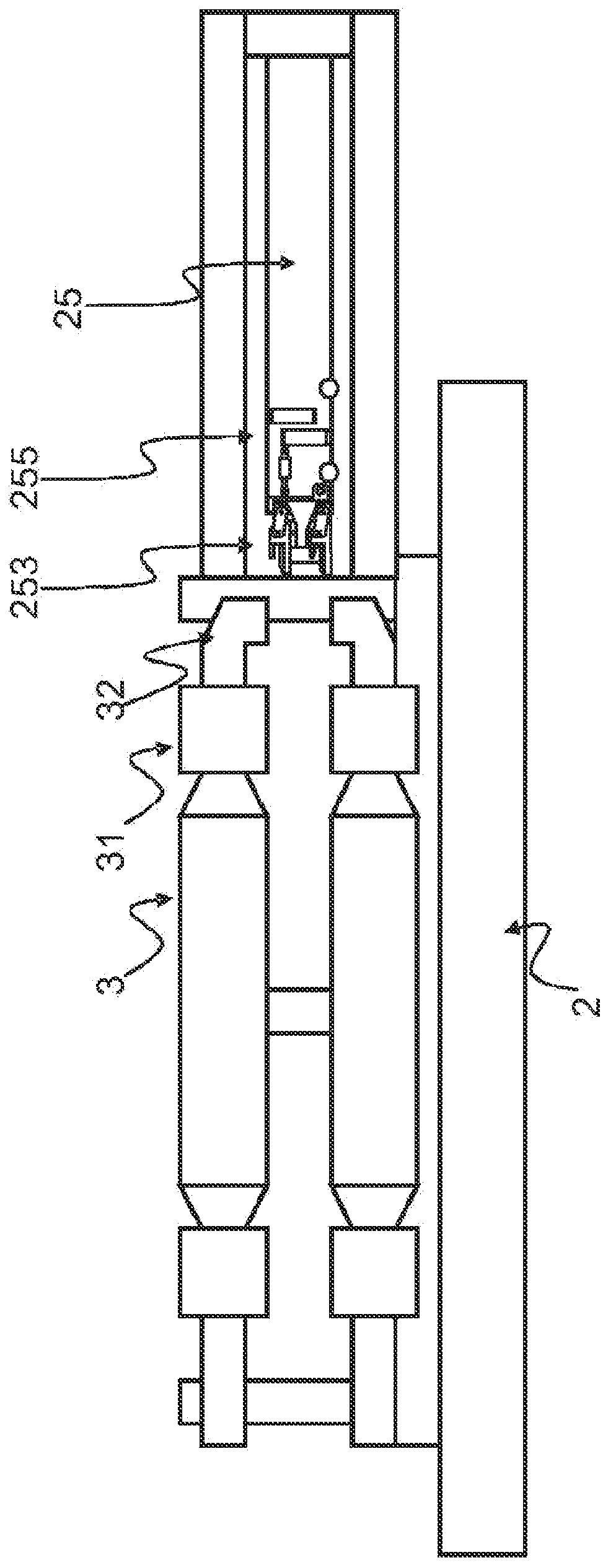

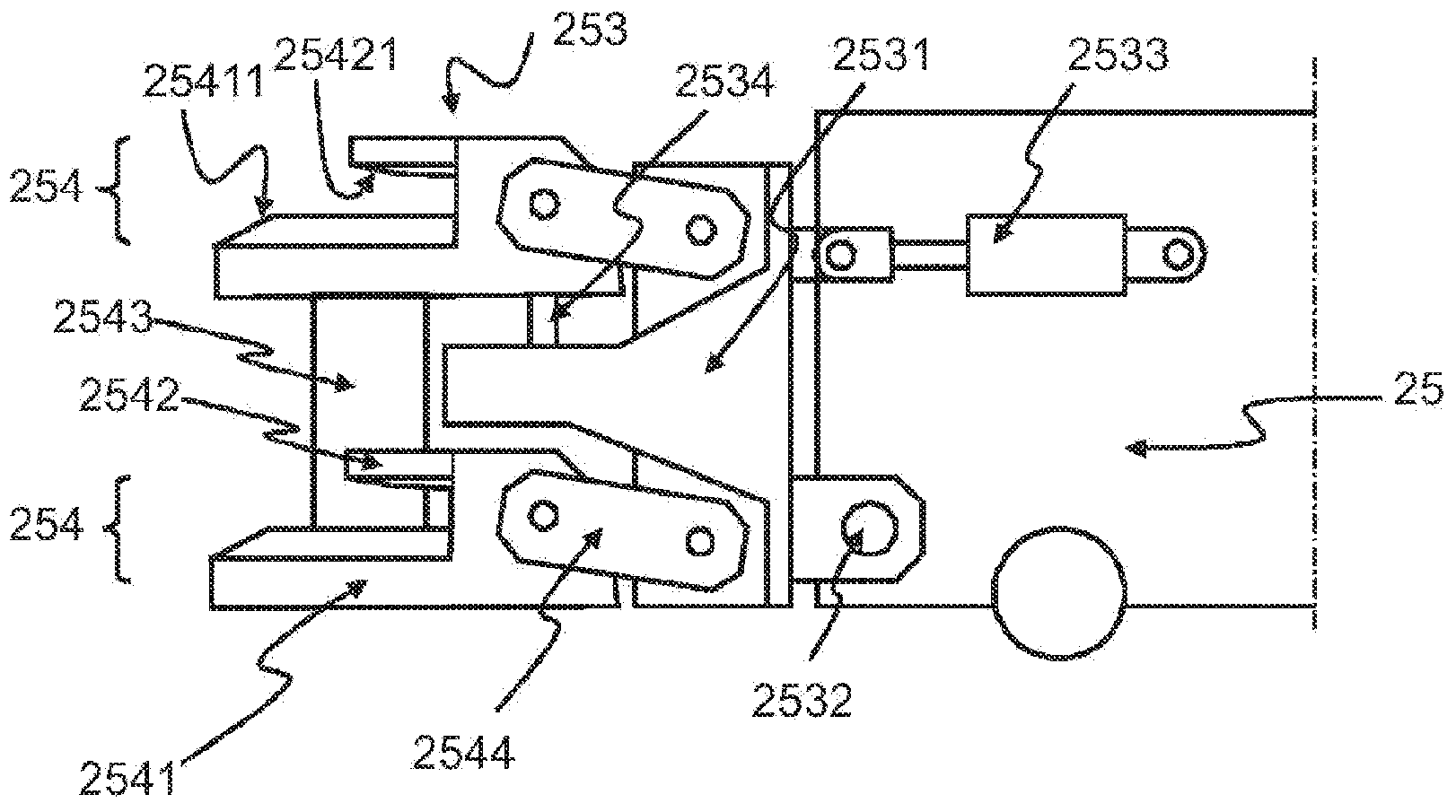

[0100] figure 1 Shows an embodiment example of a dismantling device for at least one roll and / or at least one roll group of a rolling mill stand of the side-supported six-high type according to the invention, especially for example afterward Figure 10 description of. The dismantling device is suitable for exchanging rolls and / or groups of rolls of said rolling mill stand and is capable of exchanging at least one roll and / or at least one group of rolls of said rolling mill stand. The dismantling device according to the invention comprises:

[0101] - The loading and unloading base 1, in particular positionable on the operator's side of the rolling mill installation, comprises positioning and moving means capable of ensuring its movement and positioning in a first direction parallel to the longitudinal axis of rotation of the work rolls, when the work rolls are installed on the rolling mill stand. In particular, the base 1 can move by means of the guide wheels 11, especially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com