Scribing method for axial center holes of bottom landing leg beams of large-scale gantry crane

A technology of gantry cranes and center lines, which is applied to workshop equipment, manufacturing tools, etc., to achieve the effects of saving purchase costs and special personnel, improving efficiency and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the drawings.

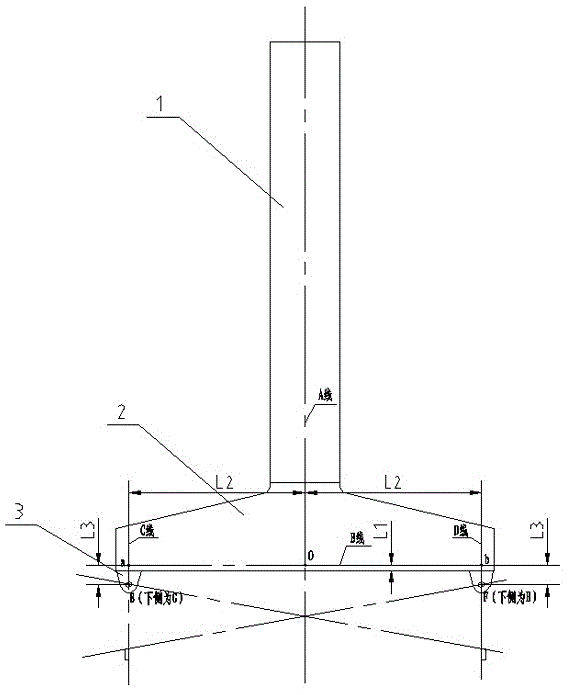

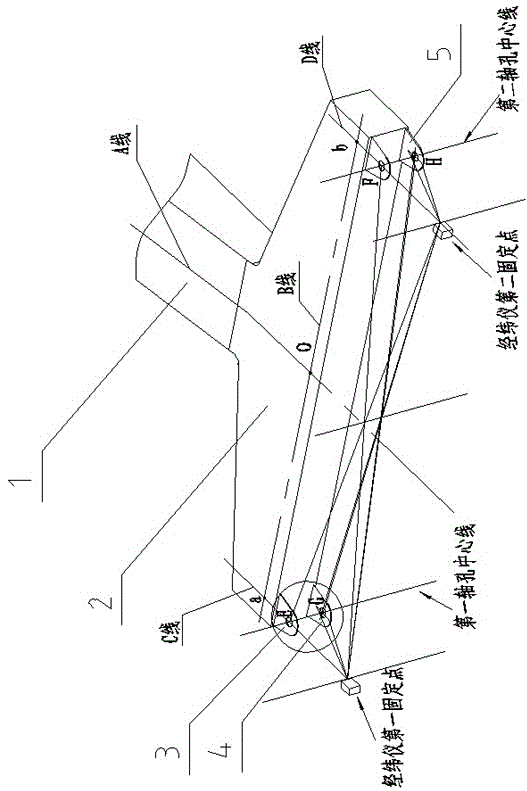

[0031] Operation process: see figure 1 , figure 2

[0032] 1. Rigid legs close up: The rigid leg columns 1 and bottom beams 2 that are qualified as a single piece are closed on the supporting platform. It is required to use a level to level the lower straight plane and cushion it firmly.

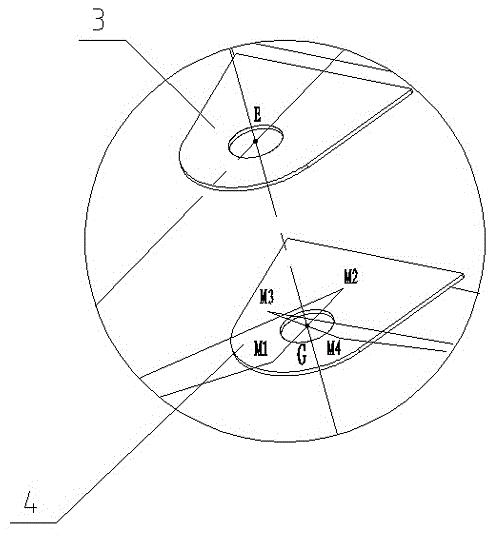

[0033] 2. After the closing is qualified, draw the overall longitudinal centerline A on the plane of the rigid leg. On the center line A, determine the point O at the lower plane L1 from the bottom beam; at this point, use theodolite to draw a line B perpendicular to the overall center line A; on the straight line B, draw L2 based on point O Determine points a and b; then use points a and b as benchmarks to draw lines C and D perpendicular to line B with theodolite; draw lines E and B of L3 on lines C and D using points a and b as the benchmarks. Point F; these two points are the center points of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com