Tool box

A container and tool technology, applied in the field of tool containers, can solve the problems of reduced operation efficiency, troublesome embedding operation, inconvenient buffer material, etc., and achieve the effect of reducing manufacturing cost and simplifying manufacturing engineering or manufacturing operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

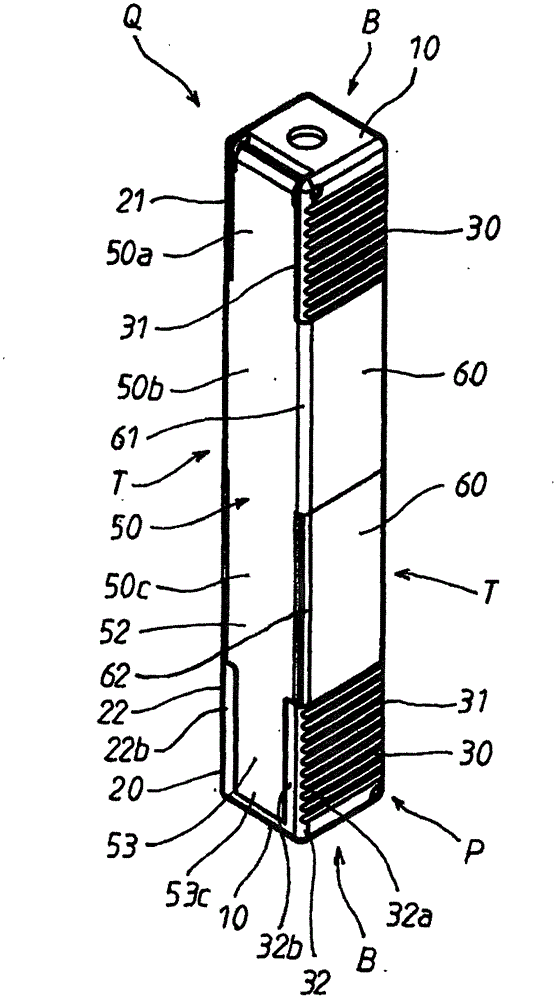

[0110] figure 1 Shown is Embodiment 1 of the tool container related to the present invention. The tool container is used for accommodating rod-shaped tools such as drill bits or end mills. The cross section of the tool container is square, and the longitudinal section of the tool container is rectangular. In addition, in the first embodiment, the overall length of the tool container is about 85 mm, and the cross-sectional size of the tool container is about 13 mm×13 mm.

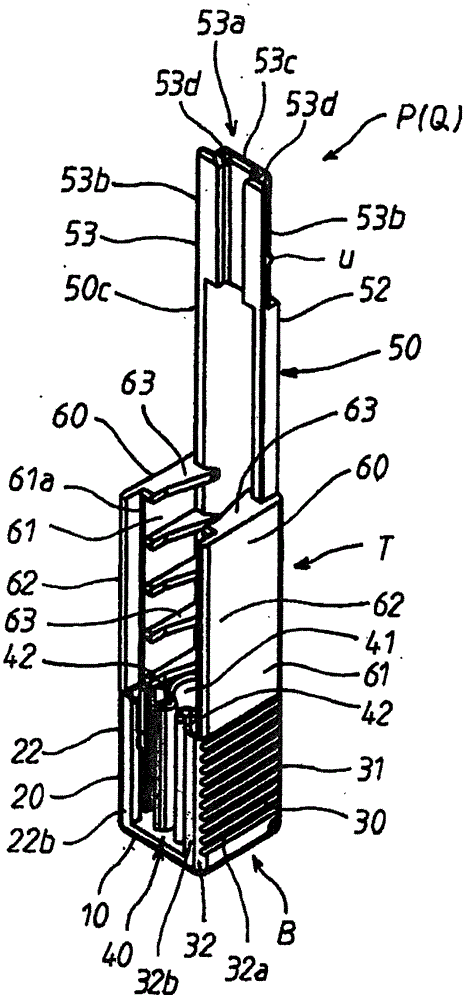

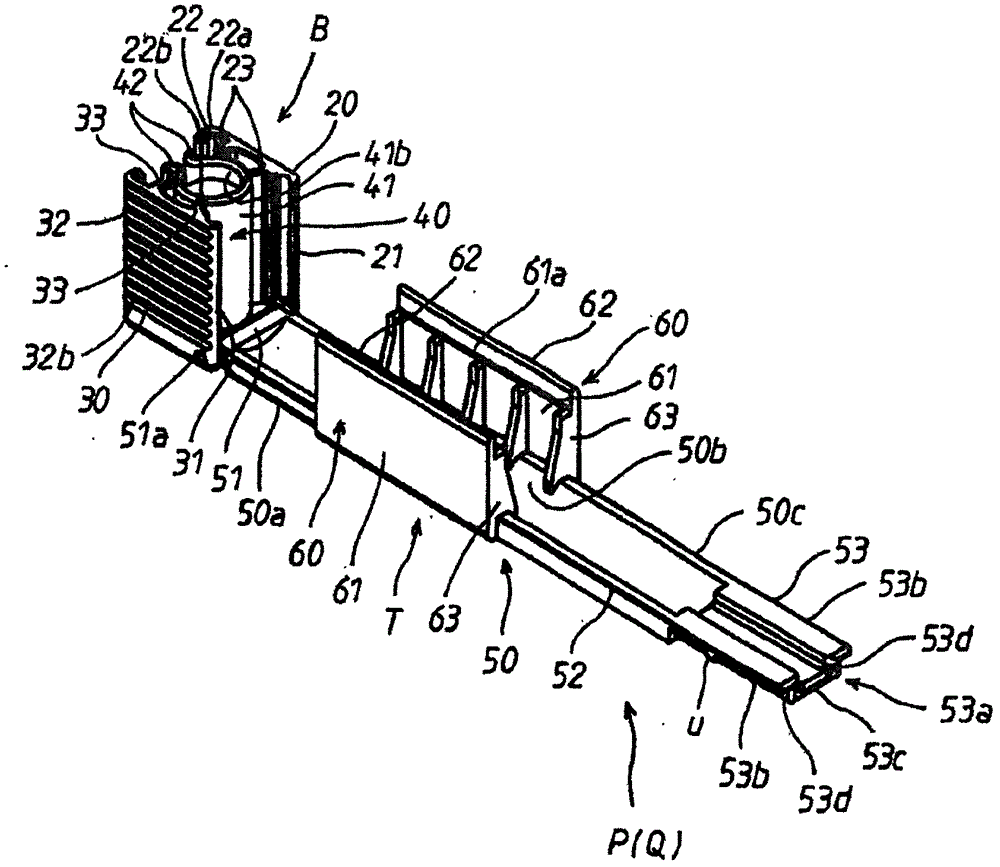

[0111] The tool container such as Figure 1 ~ Figure 4 Wherein shown in any figure, be provided with the two side container parts P, Q of elongated ruler shape.

[0112] These two side container parts P, Q are each as described later, are integrally formed and have the same structure, and these two side container parts P, Q are assembled with the mode that can disassemble each other and constitute this tool container (referring to figure 1 ).

[0113] One side container part P, such as Figure 1 to Figure ...

Embodiment 2

[0198] Figure 14 and Figure 15 Shown is the main part of the second embodiment of the tool container related to the present invention. In this second embodiment, in the two-side container parts P and Q described in the first embodiment, the bottom wall 10 of the container part B is respectively provided with a rear end 12 to replace the rear end 11, and the rear end 12 is in the On its rear end, at the respective lower rear end positions and Figure 14 The up and down directions of the icons are on the same straight line.

[0199] In addition, in the second embodiment, in the two-side container parts P and Q described in the first embodiment, the main plate 50 of the back plate material T is on the extended bottom end portion 51 of the base end plate portion 50a, through the narrow The rear end portion 12 of the bottom wall 10 of the container component B is integrally connected to the rear end portion 12 of the bottom wall 10 of the container part B so as to be rotatable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com