Functional particle and manufacturing method thereof

A manufacturing method and functional technology, applied in the field of functional microparticles and their manufacturing, can solve the problems of difficult functional substance encapsulation, exudation, poor productivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0099] The method for producing functional fine particles according to the first embodiment includes a filling step and a bonding reaction step. Next, each step will be described.

[0100] A1: Filling process

[0101] In the filling process, first, a composition containing a functional substance and a capturing substance is prepared. In the first embodiment, the functional substance is paraffin, and the main chain portion of the capture substance is a hydrocarbon oligomer, so they have strong affinity and show compatibility. First, the paraffin used is brought into a liquid state at a temperature higher than its melting point, and the capture substance is mixed therein. The ratio of the capturing substance mixed with the paraffin as a functional substance should be an amount sufficient to capture the paraffin in the pores of the porous silica as the porous fine particles. The amount of paraffin wax filled in the pores of the porous silica is in the range of 1% by weight to ...

no. 2 approach

[0111] The method for producing functional microparticles according to the second embodiment is different from the above-mentioned first embodiment in that there is a capture substance addition step between the filling step and the bonding reaction step, and the filling of the functional substance and the addition of the capture substance are taken as separate steps. process. That is, in this second embodiment, there are a filling step, a capture substance addition step, and a bonding reaction step. Next, each step will be described.

[0112] A2: Filling process

[0113] In the filling step, the pores of the porous fine particles are filled with the functional substance. First, paraffin wax, which is a functional substance, is maintained at a temperature higher than its melting point to be in a liquid state. At this time, in order to improve the fluidity of the paraffin wax, it is preferable to set the temperature sufficiently higher than the melting point. The pores of th...

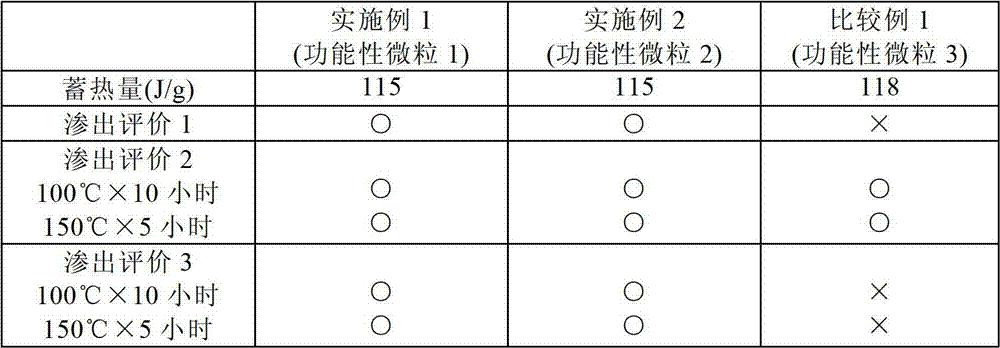

Embodiment 1

[0129] In Example 1, functional microparticles 1 using a latent heat storage substance as a functional substance were produced according to the production method of the above-mentioned first embodiment. In Example 1, porous silica (manufactured by Degsa Japan Corporation) having an average particle diameter of 100 μm was used as the porous fine particles. In addition, as the latent heat storage substance filled in the pores of porous silica, paraffin wax (Paraffin Wax-150, Nippon Seika Co., Ltd. manufacture). In addition, as the trapping material for trapping the paraffin in the pores of porous silica, a polyisobutylene oligomer having a polyisobutylene oligomer as the main chain portion and a polyisobutylene oligomer having methyldimethoxysilyl groups at both ends was used. Reactive polyisobutylene oligomer (Epion 100S, manufactured by Kaneka Co., Ltd.).

[0130] A1: Filling process

[0131] Heat 700g of paraffin wax to a temperature of 80°C above its melting point of 66°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com