Basalt fiber and graphite composite material granulating devicefor fishing reel

A technology of basalt fiber and composite materials, which is applied in the direction of mold extrusion granulation, etc., can solve the problems of low production efficiency, polluted workshop, and thin strip breakage, and achieve the effects of improving production efficiency, easy cleaning and replacement, and sufficient mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

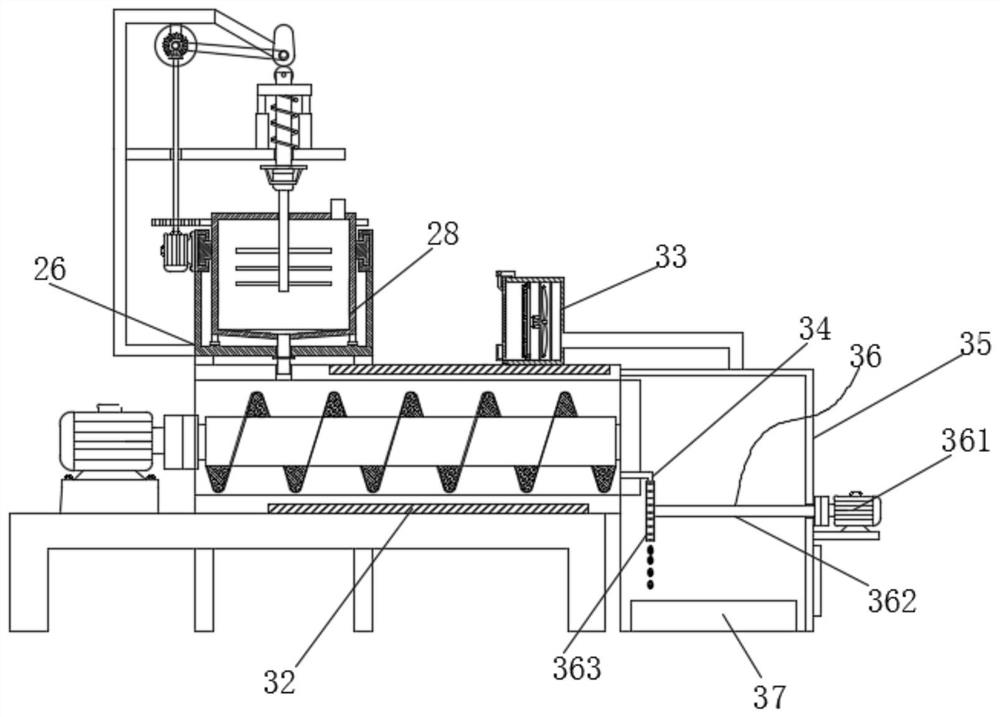

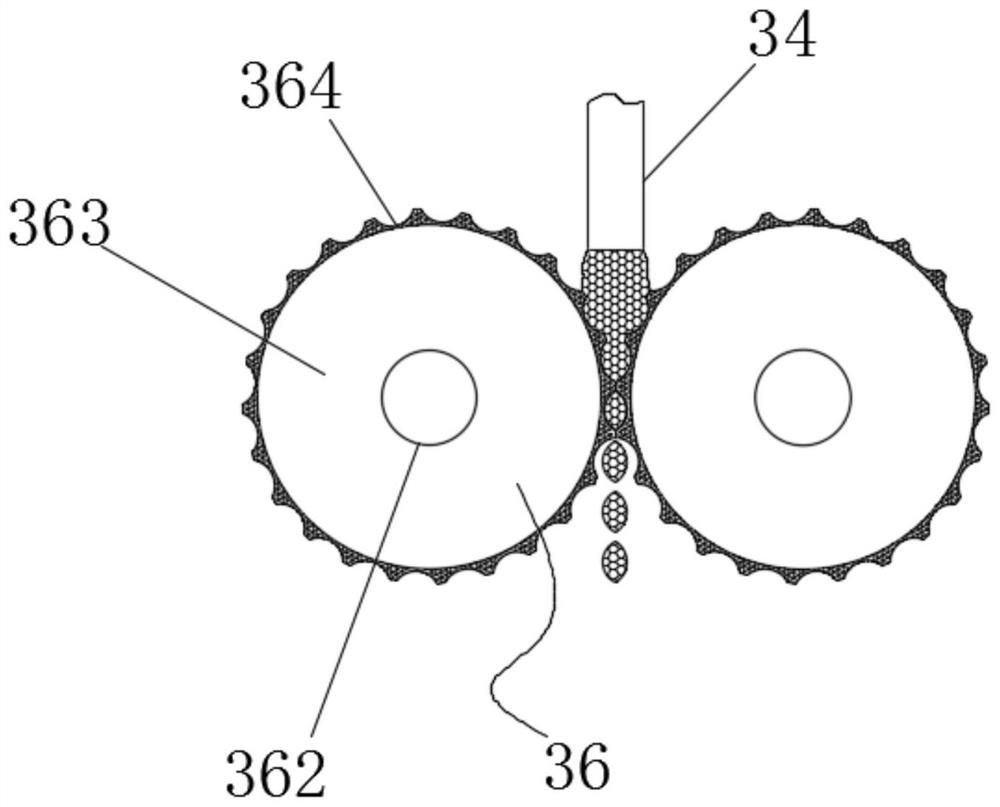

[0030] A basalt fiber and graphite composite material granulation device for fishing reels, comprising a screw extruder 32, a discharge pipe 34 is arranged at the right end of the screw extruder 32, and two groups of granulators are arranged below the discharge pipe 34 Mechanism 36, the outside of granulation mechanism 36 is provided with cooling chamber 35, and cooling chamber 35 is communicated with screw extruder 32, and the bottom of cooling chamber 35 is provided with cold water tank 37, and the top left side of screw extruder 32 has the mixing barrel 28;

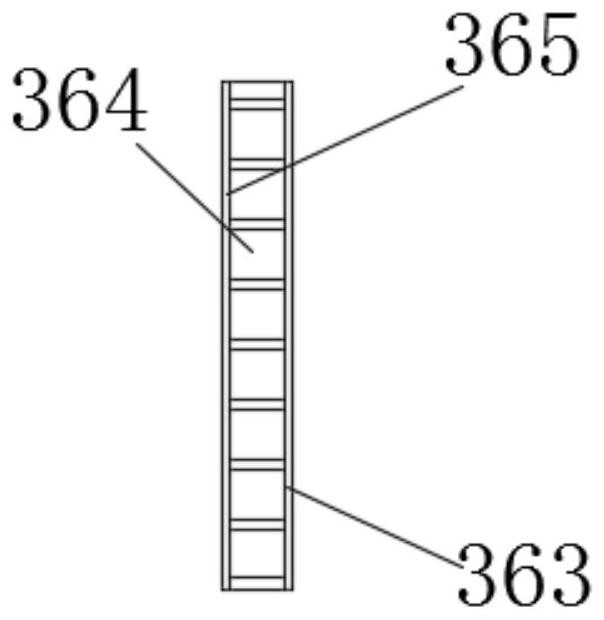

[0031] Granulating mechanism 36 comprises the 3rd electric motor 361 that is arranged on the outside of cooling chamber 35, and the output end of the 3rd motor 361 is provided with rotating rod 362, and the left side end of rotating rod 362 is provided with molding die 363, and molding die 363 is disc-shaped , the curved surface of the molding die 363 is provided with a slot 364 , the slot 364 is semi-cylindrical, and ...

Embodiment 2

[0034] As an option, see figure 1 , Figure 4 , a basalt fiber and graphite composite material granulation device for fishing reels, an odor adsorption box 33 is arranged on the right side of the upper end of the screw extruder 32; the odor adsorption box 33 includes a casing 337 arranged at the upper end of the screw extruder 32, The outer side of the box body 337 is hinged with a cover 331, the inner wall of the opening end of the cover 331 is provided with a first magnetic block 333, and the end surface of the box body 337 adjacent to the cover 331 is provided with a second magnetic block corresponding to the first magnetic block 333 334, the first magnetic block 333 is magnetically opposite to the adjacent surface of the second magnetic block 334, the inside of the box body 337 is provided with a filter screen 335, and the side of the filter screen 335 away from the cover 331 is provided with a fixed ring frame 338, the fixed ring frame The outer ring portion of 338 is fi...

Embodiment 3

[0038] As an option, see figure 1 , Figure 5 , a basalt fiber and graphite composite material granulation device for a fishing reel, comprising a mixing cylinder 28, a rotating shaft 24 is arranged inside the mixing cylinder 28, a stirring rod 25 is arranged outside the rotating shaft 24, and the upper end of the rotating shaft 24 runs through the mixing cylinder 28 and is provided with a second motor 19, the second motor 19 is arranged on the top of the mixing cylinder 28, the outside of the mixing cylinder 28 is provided with a first ring slider 22, and the outside of the first ring slider 22 is provided with a first ring slider rail 23, the lower end of the first annular slide rail 23 is provided with an outer cylinder 26, and the outer cylinder 26 is arranged on the outside of the mixing cylinder 28, and the left side of the first annular slide rail 23 is provided with a first motor 1, and the output of the first motor 1 The shaft is connected with a rotating shaft 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com