a vibrating hopper

A technology of vibrating hoppers and vibrating parts, which is applied in the field of machinery, can solve the problems of large vibration radian and affect the stability of the lower hopper connection, and achieve good vibration reduction effect, high practical value, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

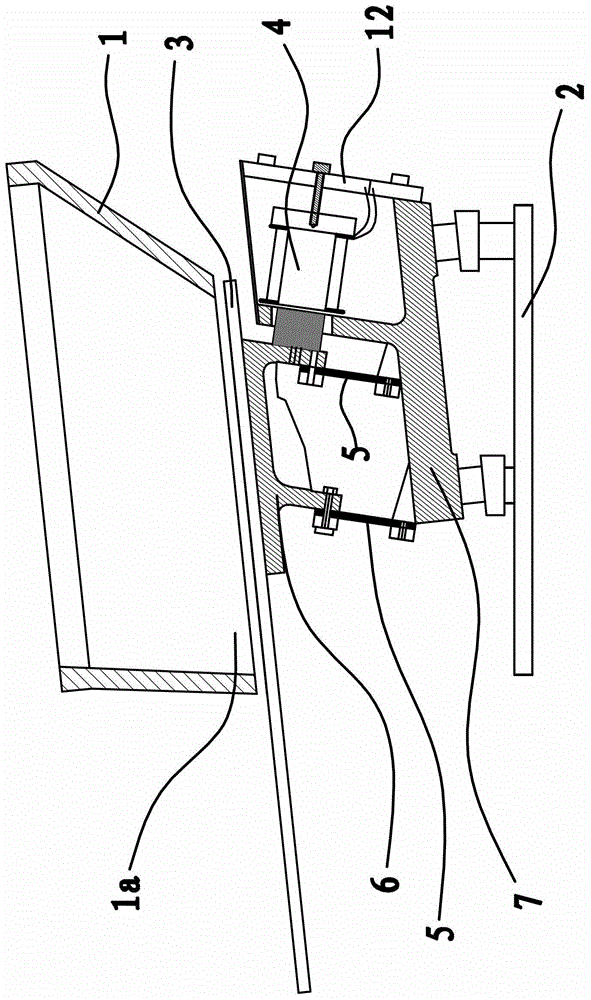

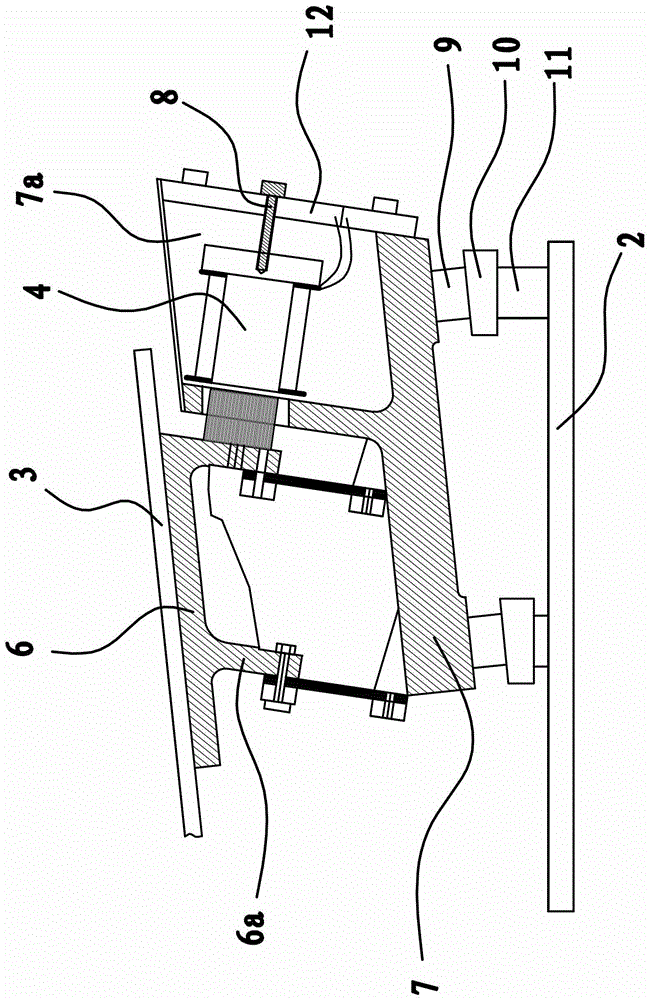

[0032] Such as figure 1 As shown, the vibrating hopper includes a funnel-shaped body 1, the bottom of the body 1 has a discharge port 1a, the body 1 is fixed on the bracket 2, and it also includes a blanking plate 3, a vibrating member 4, an elastic member 5, and a connecting frame One 6 and connecting frame two 7.

[0033] Such as figure 1 and figure 2 As shown, the blanking plate 3 is in the shape of a straight plate, and the bottom of the blanking plate 3 is fixedly connected with a connecting frame one 6, and the connecting frame one 6 has a protruding connecting portion 6a. The blanking plate 3 is obliquely located at the outlet 1a of the body 1 . The second connecting frame 7 is fixedly connected to the support 2, and there is a vibration damper between the second connecting frame 7 and the support 2. The second connecting frame 7 has an installation cavity 7a, and the vibrating element is located at the installation cavity 7a. In this embodiment, the installation c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap