Utilization method for movable chute for concrete pouring of monolithic track bed of modern tramcar

A technology of integral ballast bed and tramway, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of concrete waste, long pouring section, small cross-sectional area of molded concrete, etc., to reduce construction cost, reduce safety risk, The effect of saving the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

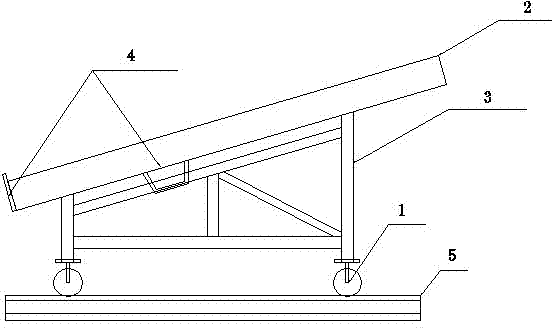

Image

Examples

Embodiment

[0039] Line 1 of the modern tramway first phase project in Hunnan New City, Shenyang City, Liaoning Province adopts this method of construction:

[0040] After comparing the installation costs of two sections of grooved rail integral ballast track laying project with the same structure type in this project, this installation method can save 0.5 days of construction period and save construction and safety measures for every 300 meters of grooved rail track laying project. The investment cost is 271 yuan; the total 24,000m track laying project of this project adopts this installation method, which saves a total construction period of 80 days, and saves a total of 21,680 yuan in construction and safety measures.

[0041] The construction technology of the mobile chute for the concrete pouring of the integrated track bed of modern trams is not adopted, and the main labor, machinery and material inputs of the 300m track concrete pouring constructed by the traditional construction te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com