Automatic lifting type assembling highway steel bridge transporting and erecting vehicle

An automatic lifting and erecting vehicle technology, which is applied in the erection/assembly of bridges, bridge construction, bridges, etc., can solve the problem that the handling equipment cannot fully meet the needs of the project, and achieve improved operating efficiency, obvious advantages, and enhanced mobility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

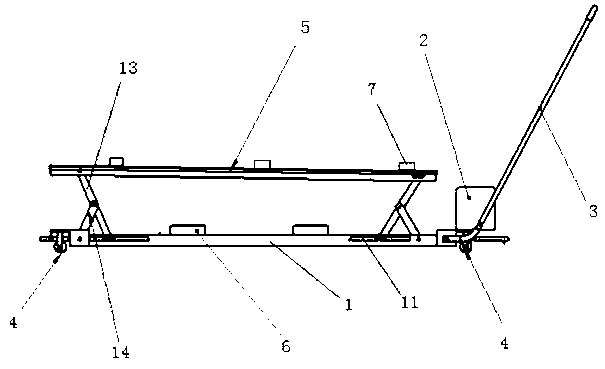

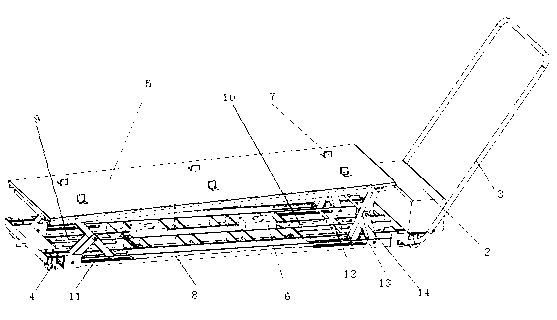

[0038] see figure 1 Referring to Fig. 3 , the assembled highway steel bridge automatic lifting type handling and erecting vehicle includes a base 1, an electric control box 2 and a handrail 3 are provided at the rear end of the base 1, and a lifting shelf 5 is arranged on the base 1, and the base 1 A motor 6 for starting the lifting rack 5 is arranged inside, and the motor 6 is connected with the electric control box 2 through wires.

[0039] Wherein, the base 1 is provided with two front and rear motors 6, the front end of the front motor is connected to the front end of the base 1 through the front transmission shaft 9, and the rear end of the rear motor is connected to the rear end of the base 1 through the rear transmission shaft 10; Both sides of the front and back of the base 1 are provided with a rectangular through hole 11; the transmission shaft 10 is equipped with a rotating rod 12, and the two ends of the rotating rod 12 pass through the rectangular through holes 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com