Check valve

A check valve and check sheet technology, applied in the field of residential shared exhaust systems, can solve the problems of increasing materials, labor costs, deviations in production and installation, affecting the sealing effect, etc., saving materials and labor costs, and increasing overall strength. , a strong overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

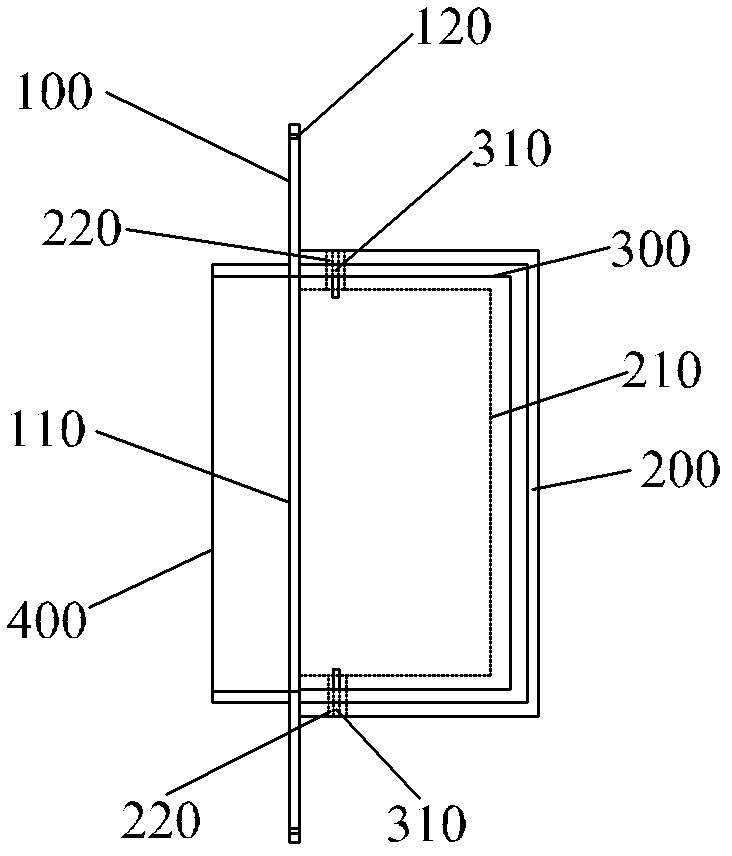

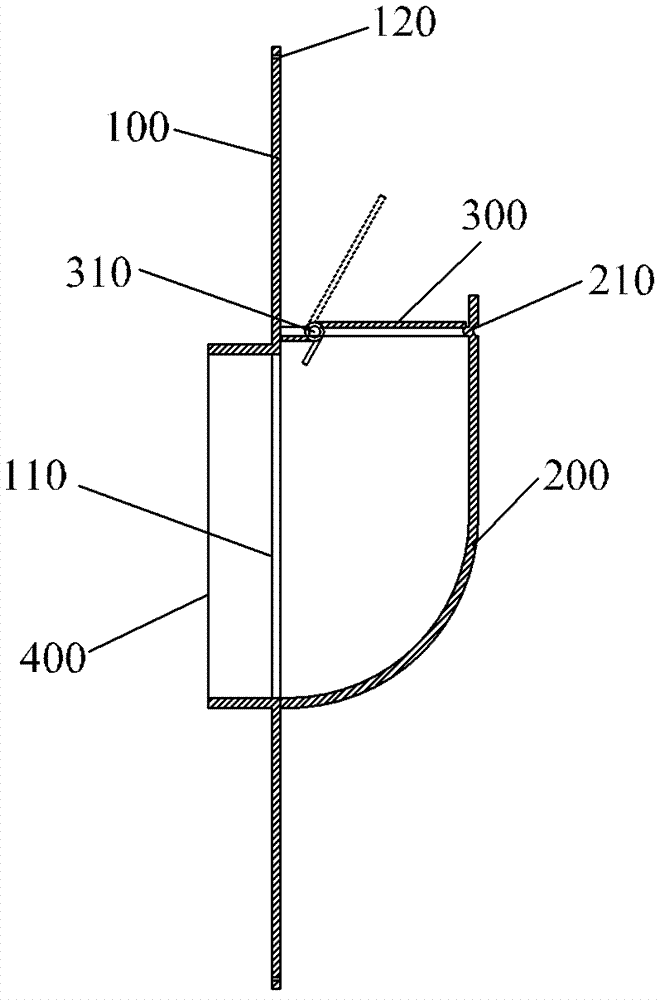

[0016] refer to figure 1 ,, figure 2 , is a schematic diagram of the structure of the check valve in the first embodiment of the present invention. The check valve in this embodiment is located at the air inlet of the residential common exhaust system. The check valve includes a panel 100 provided with an air inlet 110, a guide pipe 200 arranged inside the panel 100 and communicating with the air inlet 110, and a normally closed valve which is arranged on the guide pipe 200 and can cover the outlet 210 of the guide pipe. Check sheet 300. At least two side walls of the guide tube 200 are provided with a first inner convex outer concave belt 210 , and the normally closed non-return piece 300 is superimposed and closed with the first inner convex outer concave belt 210 . in, figure 2 The middle dotted line shows the state when the normally closed non-return piece 300 is opened. The first inner convex outer concave belt 210 of the check valve in the present invention is sta...

no. 2 example

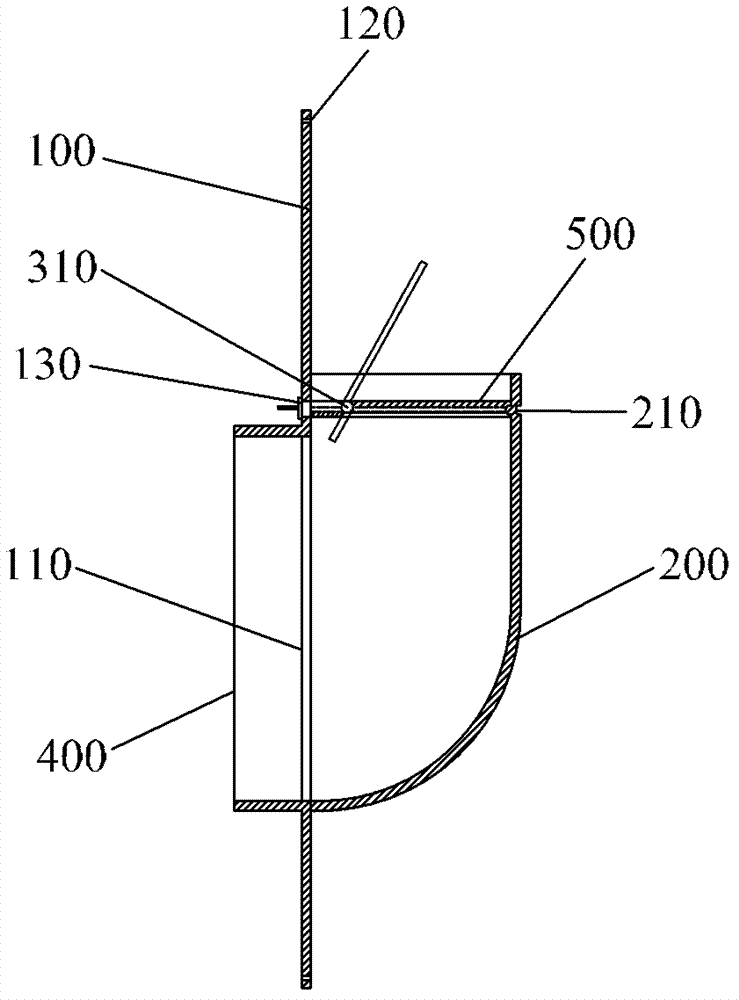

[0025] refer to image 3 , is a schematic cross-sectional view of the second embodiment of the check valve provided by the present invention. The difference between this embodiment and the first embodiment is that the panel 100 is provided with an opening 130 , and the guide tube 200 is provided with a normally closed non-return device 500 which can be pulled out from the opening 130 and inserted. The normally closed non-return device 500 cooperates with the first inner convex outer concave belt 210 of the guide pipe 200 to position and slide, and is pulled out or inserted from the opening 130 of the panel 100, thus facilitating the cleaning and replacement of the normally closed non-return device 500. The normally closed check device 500 can be made of plastic or metal. image 3 The middle dotted line shows the state when the non-return piece of the normally closed non-return device 500 is opened. Other structures of the check valve in this embodiment are the same as those ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com