Production process of UHPC facing integrated prefabricated concrete member

A technology of prefabricated concrete and production technology, applied in the direction of manufacturing tools, ceramic molding machines, ceramic molding cores, etc., can solve the problems of prolonging the construction period, poor integrity, and increasing construction links, etc., to prevent cracking, strong integrity, and increase strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

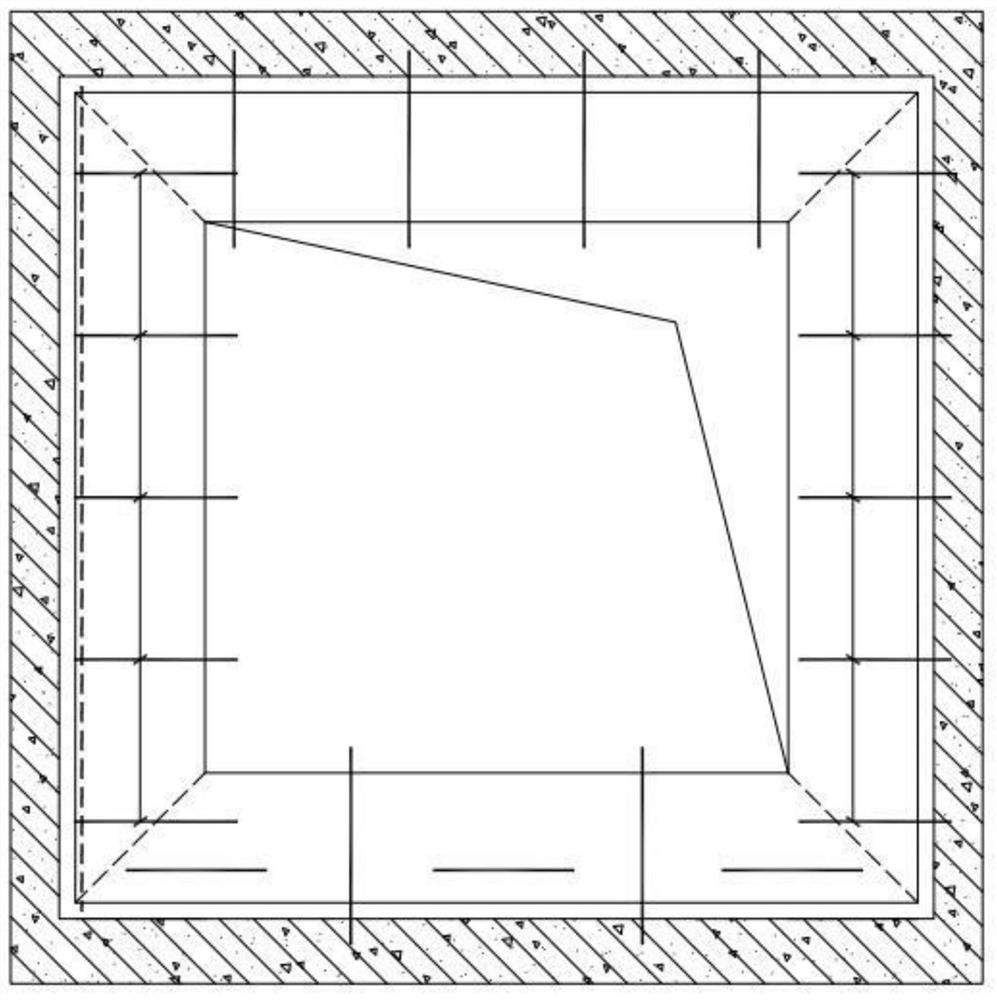

[0021] like figure 1 A specific embodiment of the UHPC facing integrated precast concrete component production process of the present invention is shown, including the following steps:

[0022] A) Reverse molding of UHPC veneer layer: According to the design requirements of the veneer, the corresponding steel molds, including the bottom mold and the mold core, are processed and produced, and the connecting ribs in the veneer are bound according to the requirements of the outer veneer shape of the drawings. , Bind the inner stirrups and long bars of the UHPC facing layer to the inner mold core, and use a spacer to ensure the thickness of the outer protective layer of the steel bar, and then fix it in the bottom mold with the mold core, and reserve UHPC decoration. The space for the surface layer to be formed, and the stirred UHPC slurry is poured from the side of the cavity reserved for the UHPC facing layer into the cavity reserved for the UHPC in the bottom mold until it emer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com