Batch preparation continuous single-processing prediction control scheduling method

A technology of predictive control and scheduling method, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

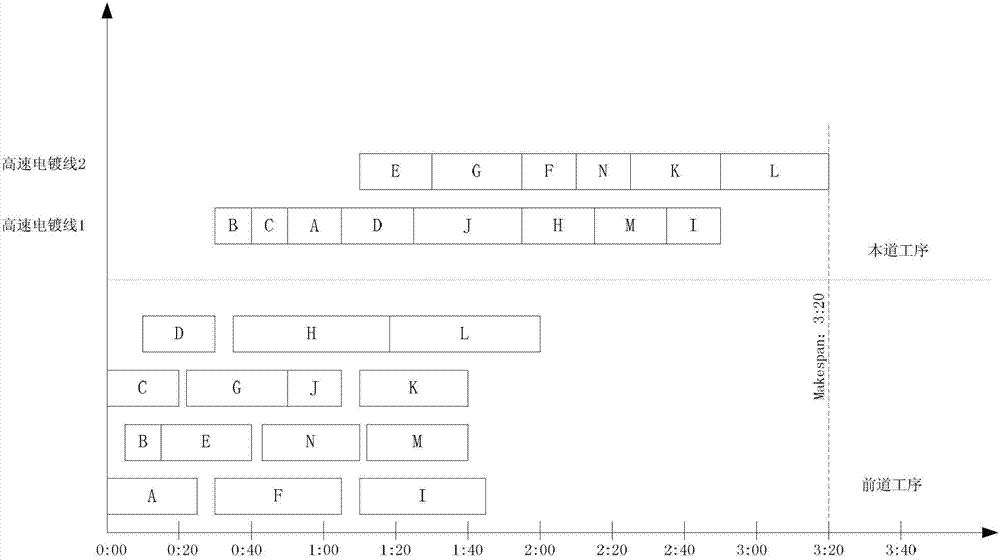

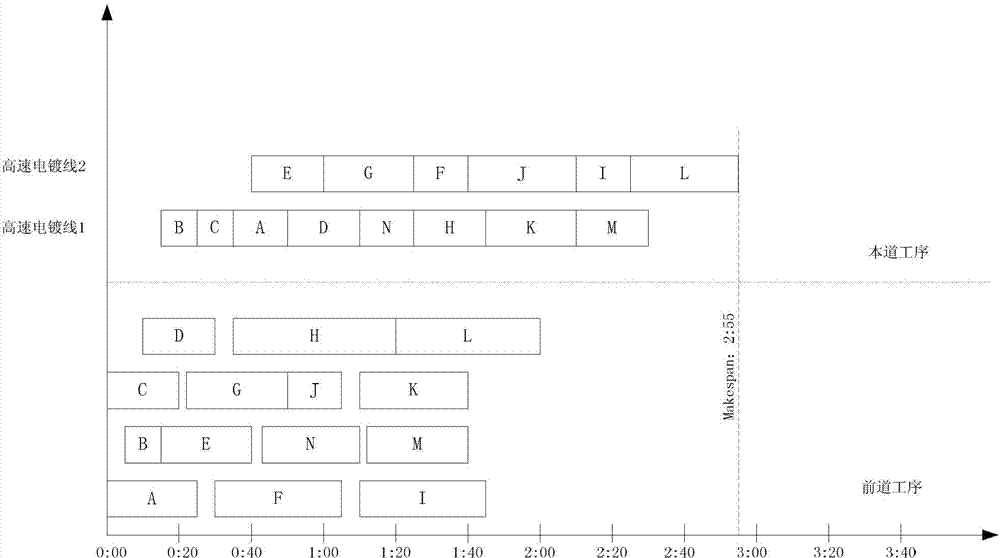

[0029] The overall flowchart of the predictive control scheduling method for batch preparation and continuous order processing in the present invention is shown in the attached figure 1 shown. Taking the electroplating process in the semiconductor back-end manufacturing process as an example to illustrate, figure 2 , image 3 Result plots of different scheduling methods. in, figure 2 In order not to predict in advance, an example diagram of manual scheduling that is commonly used by enterprises to start processing after a certain batch is met; image 3 An example diagram of predictive control scheduling proposed by the present invention. Comparing these two figures, it can be known that the use of the predictive control scheduling algorithm of the present invention meets the requirements of Makespan, minimizes the maximum completion tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com