SMT (Surface Mounting Technology) welding spot image segmentation method

An image segmentation and solder joint technology, applied in image analysis, image data processing, instruments, etc., can solve the problems of neglecting class cohesion, inability to segment, wrong segmentation, etc., to improve segmentation quality, avoid wrong segmentation and inability to split effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

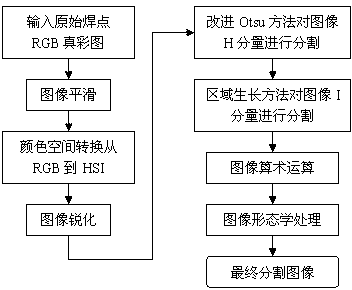

[0031] A method for segmenting images of SMT solder joints, comprising the following steps:

[0032] 1. Preprocessing the original solder joint RGB true color image: including the smoothing of the solder joint color image, the conversion of the color space from RGB to HIS, and the sharpening of the solder joint image.

[0033] (1) Smoothing of color images of solder joints:

[0034] The specific form of solder joint color image smoothing is:

[0035] f _ ( x , y ) = 1 N Σ ( x , y ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com