Device and method for rolling forming of spindle nose of vehicle axle of semi-trailer difficult to form

A semi-trailer axle and roll technology, applied in the direction of metal rolling, can solve the problems of increasing energy consumption and reducing the output of rolling mills, achieving significant technological progress, avoiding secondary rolling, and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings.

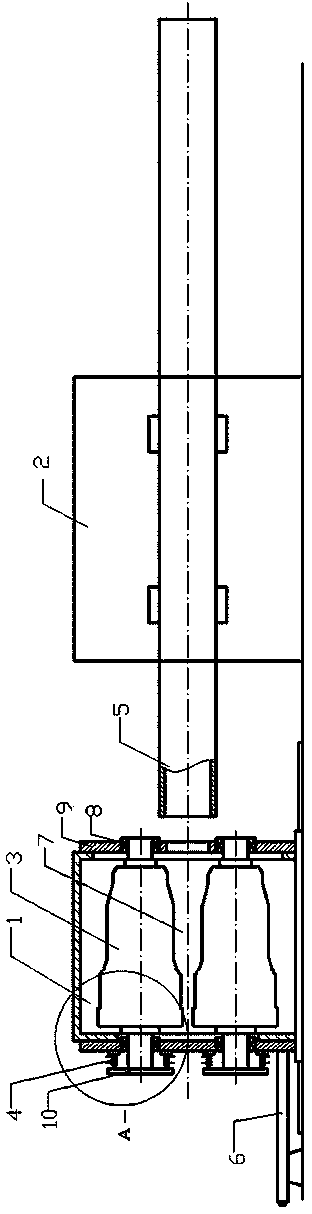

[0020] Such as figure 1 As shown, the axle end rolling device mainly includes a roll box 1 (containing four rolls 3 arranged symmetrically in the circumferential direction of the shaft blank) and a shaft blank rotating box 2 (holding and driving the shaft blank 5 to rotate). The non-feeding end of each roll 3 is provided with two symmetrically distributed hydraulic mechanisms 4, through which the axial position of the rolls can be adjusted.

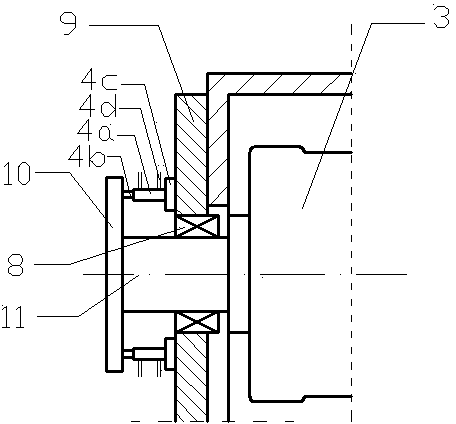

[0021] On the basis of the existing semi-trailer axle shaft head rolling equipment, an axial adjustment device is added to each roll. Such as figure 2 As shown, both ends of each roll are equipped with axially movable bearings 8, and the axial movement of the rolls is realized by hydraulic mechanism 4. The hydraulic mechanism 4 is composed of a hydraulic cylinder 4a, a piston rod 4b, a base 4c of the hydraulic cylinder, and a hydraulic pipe 4d. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com