Rail rolling production line and rail rolling process applying same

A production line and track technology, applied in the track rolling production line and track rolling technology field, can solve the problems of difficulty in adapting to the production of light rail and elevator guide rail products, poor product quality control, low production efficiency, etc., and reduce the production capacity per ton of steel The effect of reducing consumption and labor intensity of workers, improving product quality and product yield, increasing rolling speed and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

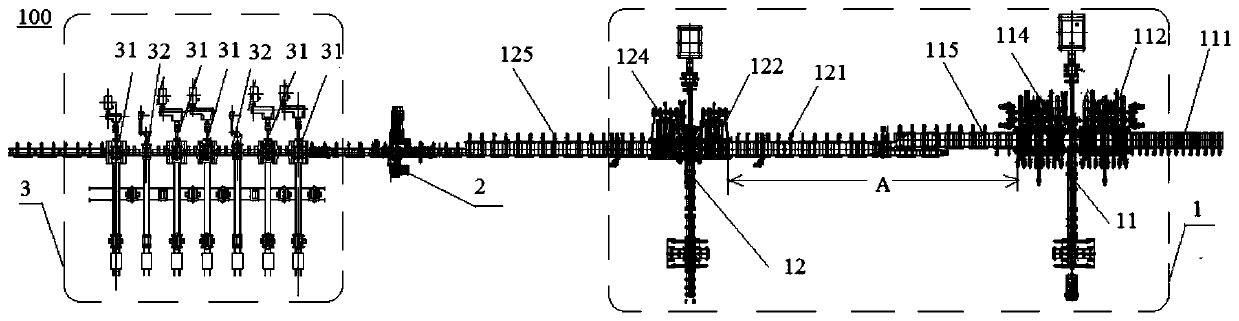

[0025] figure 1 It is a structural schematic diagram of the track rolling production line 100 according to the present invention. The orbital rolling production line 100 comprises: a rough rolling unit 1, the rough rolling unit 1 includes a first billet mill 11 and a second billet mill 12 which are arranged off the head; a finish mill unit 3 arranged behind the second billet mill 12 , the finishing rolling group 3 includes at least four finishing rolling stands arranged in sequence; Wherein, both the first blanking machine 11 and the second blanking machine 12 are configured to be capable of reciprocating rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com