Multi-dimensional controllable modularization six-roller mill

A six-high rolling mill, modular technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve problems such as difficult to overcome roll buffer force, unfavorable rolling control, unfavorable control stability, etc. Achieve the effect of improving the comprehensive controllability and adaptability, improving the dimensional accuracy of rolling control, and improving the controllability of multi-directional adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

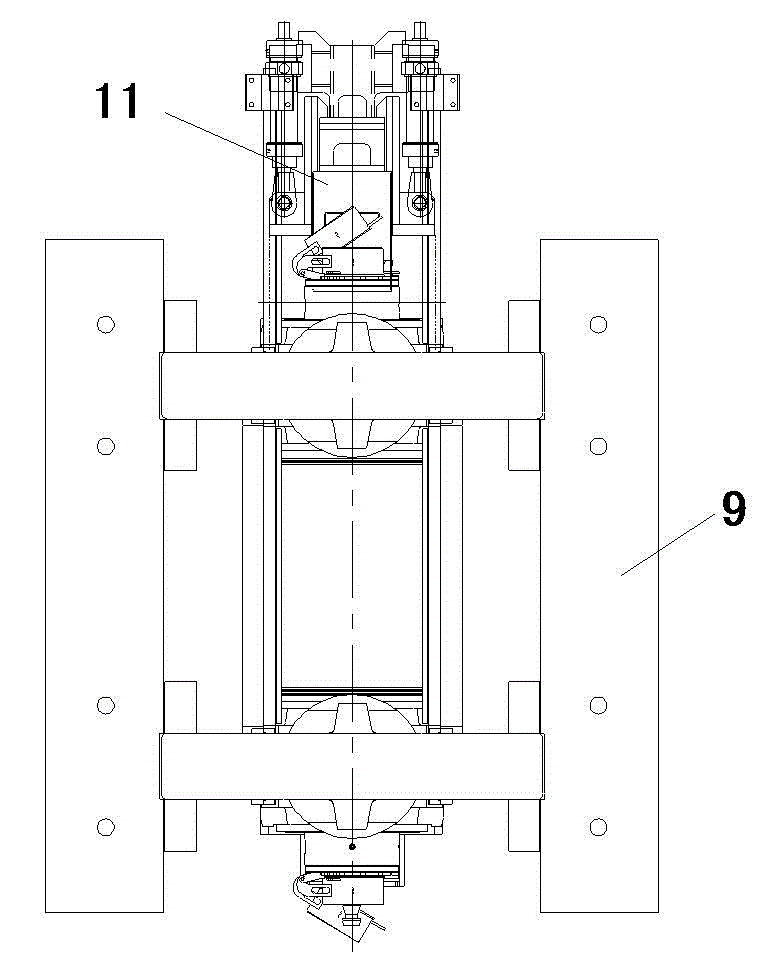

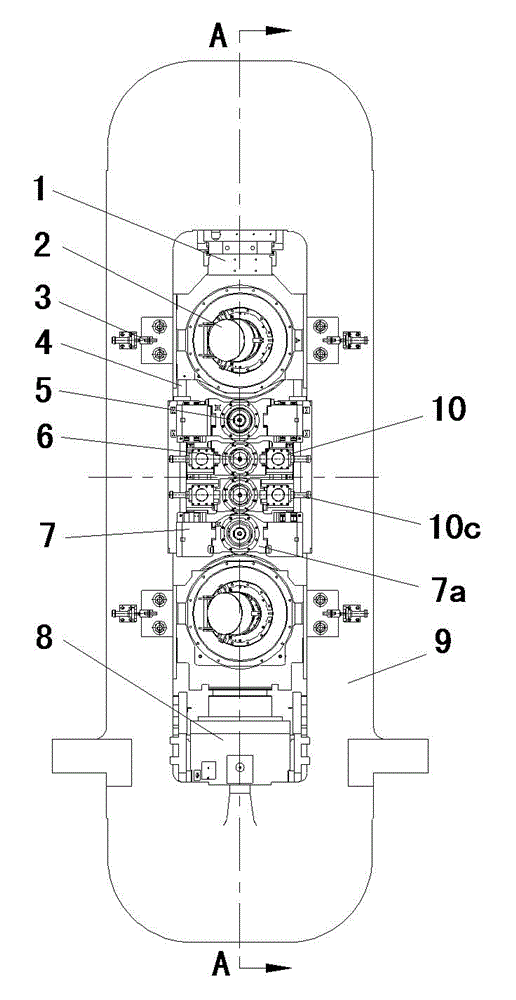

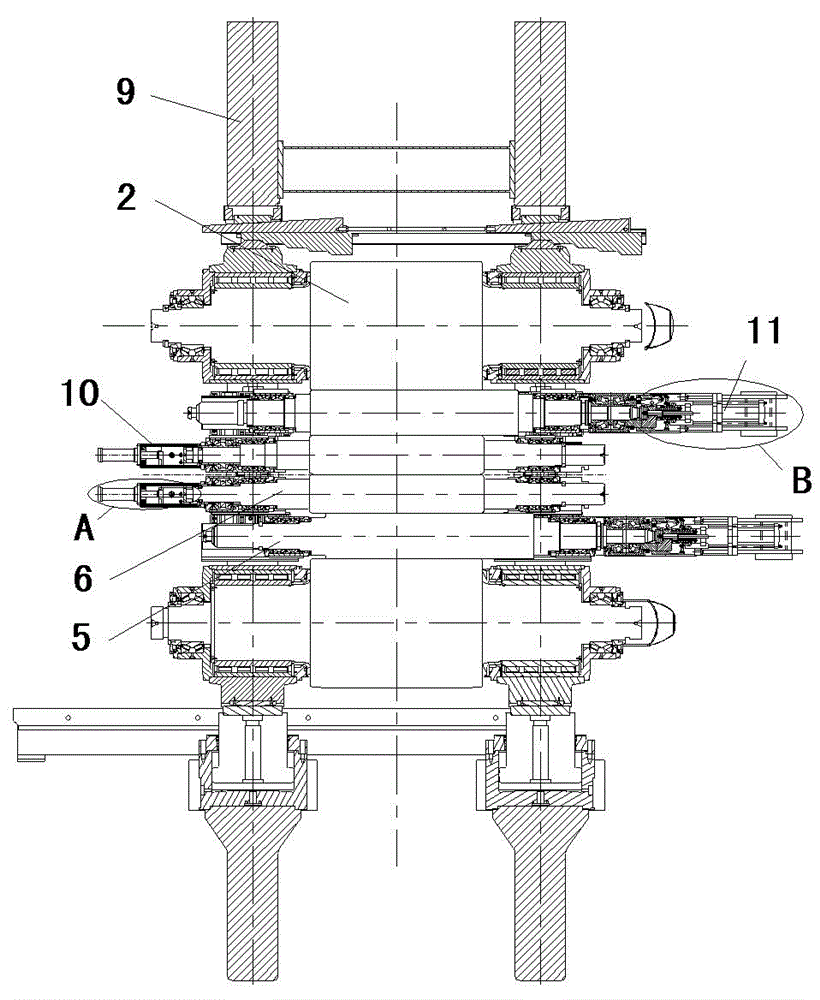

[0039] Such as figure 1 As shown, it is a schematic structural diagram of an embodiment of a multi-dimensional controllable modularized six-high rolling mill of the present invention; figure 2 for figure 1 bottom view of image 3 for figure 2 A-A cutaway view.

[0040] The multi-dimensional controllable modularized six-high rolling mill of this embodiment includes a archway 9, a roll system, an axial locking device 3 installed on the operation side of the archway 9 and connected with the backup roll 2, installed on the The hydraulic roll bending device 7 on the window in the middle of the archway 9, the backup roll balancing device 4 installed on the archway 9 and connected to the backup roller 2, the roll compensation device 1 installed on the top of the archway 9 and the roller system compensation device 1 installed on the archway 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com