A Welding Process of Automobile Handle

A welding process and technology for automobile handles, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve problems affecting the performance of handles, shape changes of pads and body assembly surfaces, etc., to solve assembly problems and avoid unnecessary The effect of weld seam and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with specific embodiments.

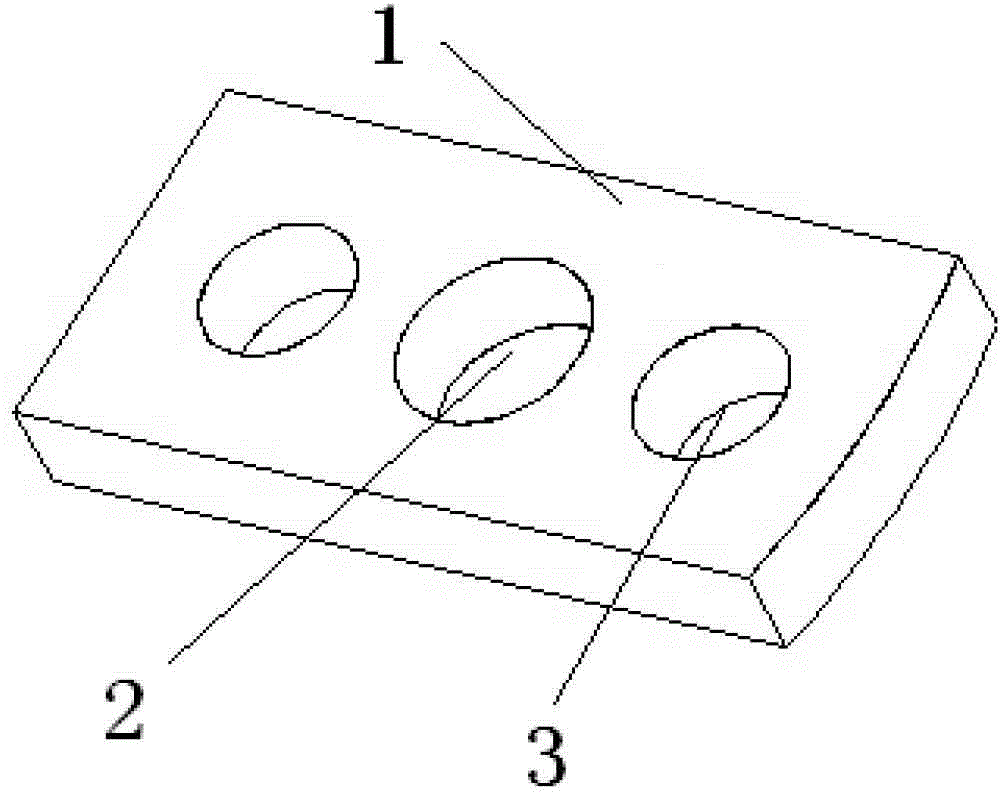

[0014] In this embodiment, a rectangular steel plate is selected as the block 1 of the automobile handle, and a mounting hole 2 and two welding process holes 3 are processed on the plate. The structure of the block 1 is as follows figure 1 As shown, the length is 45 mm, the width is 20 mm, and the thickness is 5 mm. The welding process hole 3 is located on both sides of the mounting hole 2, and the distance from the mounting hole is 4 mm. The diameter of the welding process hole is 8 mm.

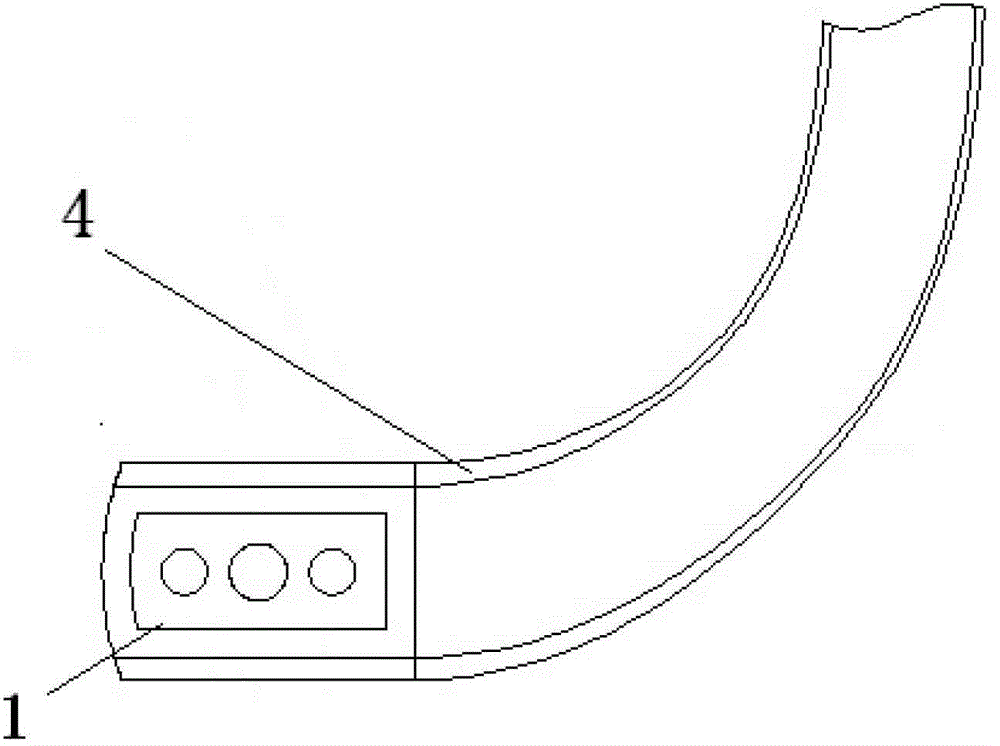

[0015] Then pad 1 is attached to the welded part on the handle body 4, as figure 2 As shown, align the mounting hole 2 with the bolt hole on the handle body. After positioning, use carbon dioxide shielded welding for welding. The tip of the welding torch is aimed at the gap between the pad in the welding process hole and the handle body, and welded to the gap. When the metal welding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com