Coast wave absorbing group pile structure

A technology of coastal and group piles, applied in the direction of coastline protection, shore piers, shore walls, etc., can solve problems such as pollution, limited role of embankment engineering, damage to the seabed environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

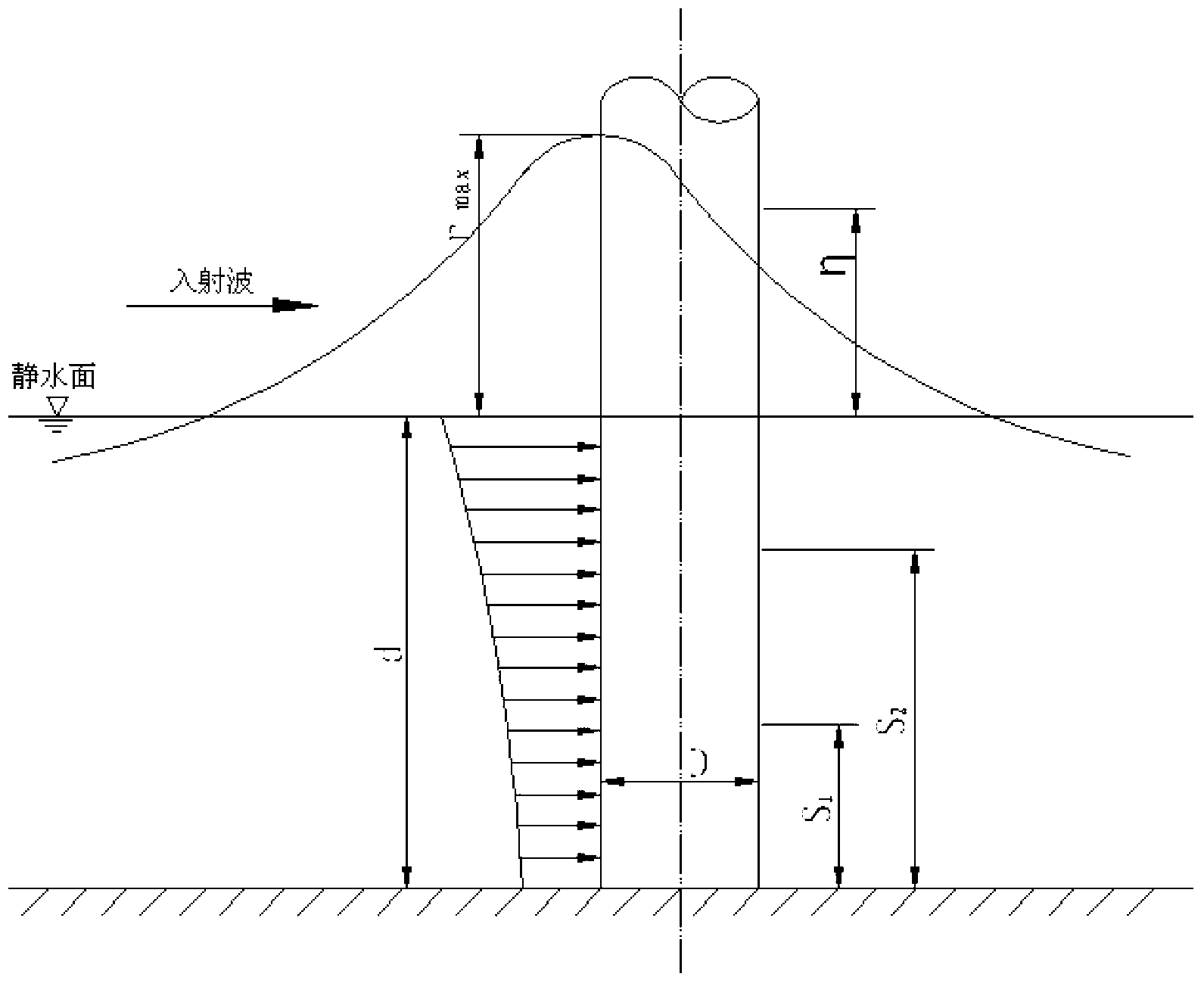

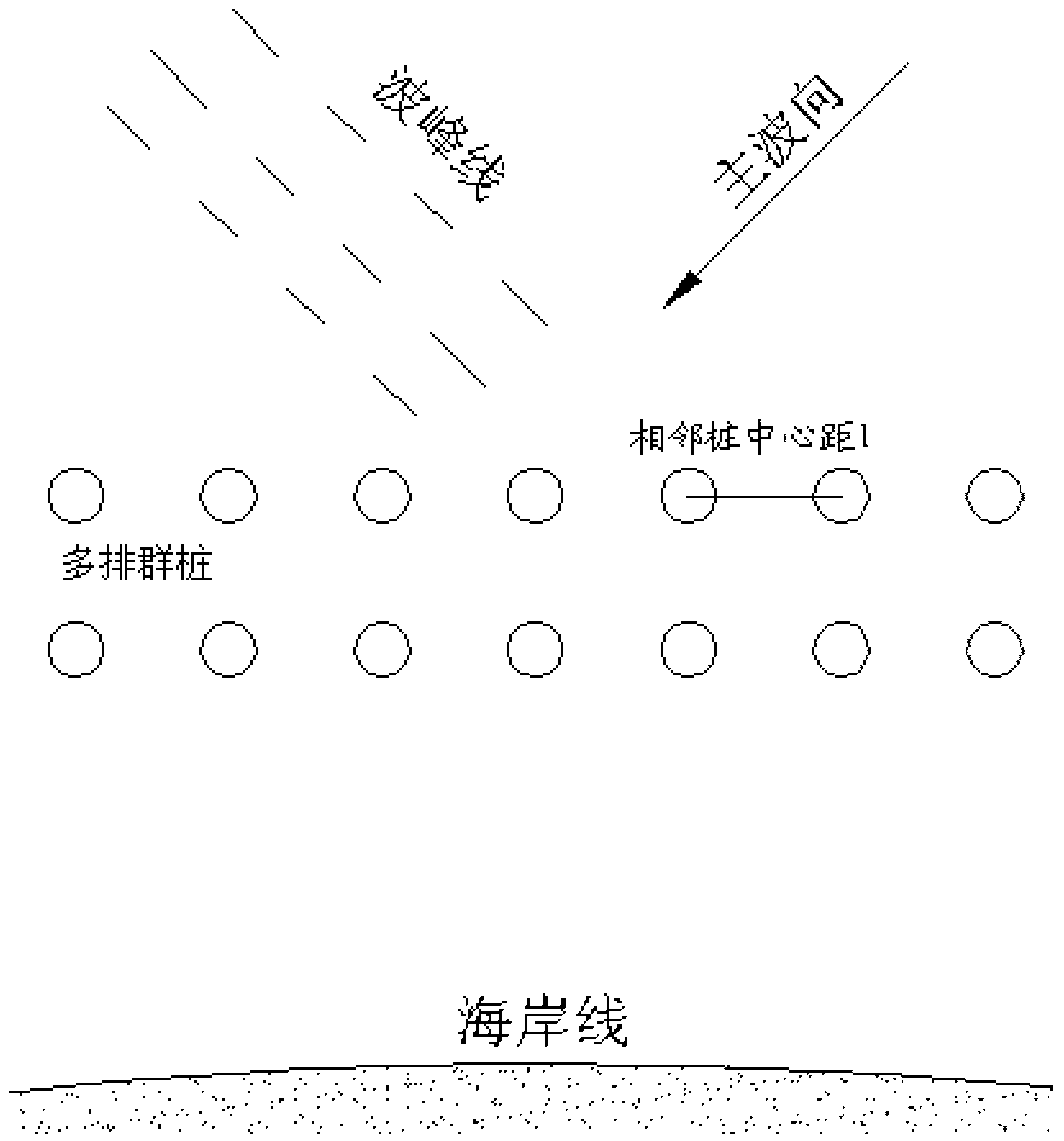

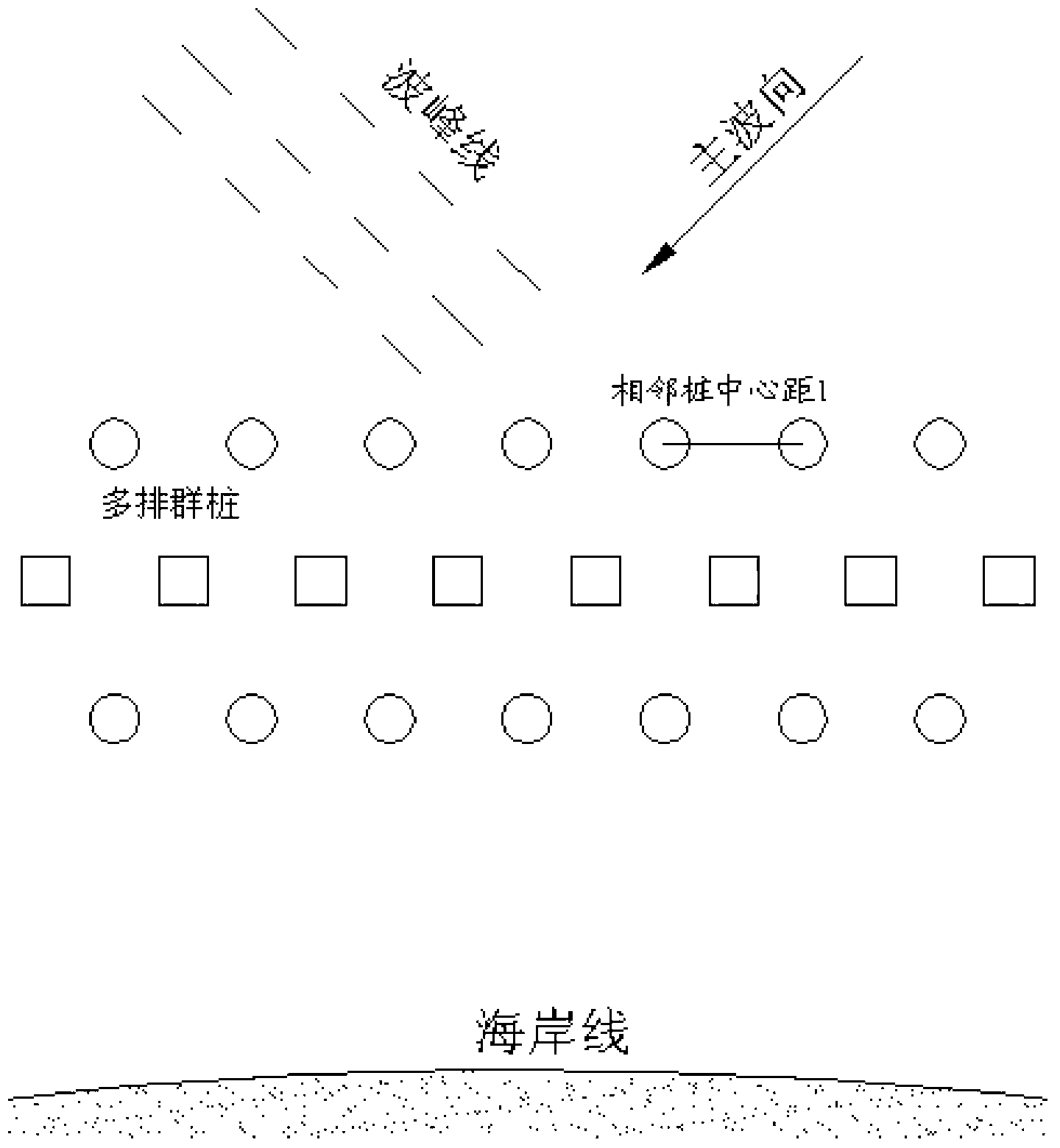

[0042] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0043] According to the specific situation, fully consider and design according to the lateral load borne by the pile, the properties of the entire soil layer through which the pile passes, the resistance coefficient of the pile side soil, the bending stiffness and strength of the pile body, among which the section size of the pile, Pile spacing and pile placement are major aspects of the design.

[0044] The construction of the pile group structure adopts prefabricated pile technology, and the construction scheme is formulated by referring to the construction methods of offshore platforms, cross-sea bridge piers and other high-pile underwater structures.

[0045] Concrete design steps of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com